Method for controlling secondary stickies through lipase

A technology of lipase and stickies, applied in the field of waste paper pulping and papermaking, to achieve the effects of low production cost, increased authenticity rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Use lipase to control the secondary glue in the production process of waste piles.

[0035] Take 30GDIP and OCC dried pulp and dilute 3%thickness. Under the amount of different lipase adding, the old news paper DIP and OCC pulp are treated.The hydrolysis rate of triglycerides is greater than 96%, lipase transfers, and lipid synthesis rates are less than 2%.120min.

[0036]According to the literature SARJA T, Zabihian M And Kourunen P. Control of Potential Secondary Stickies in Deinked Pulp. 2003 TAPPI FALL Technology Conference, Paper 22-2-2.The sedimentation of the sedimentation of the colloidal substance caused the turbidity value of the system. The difference in turbidity difference is the change value of the turbidity and initial turbidity of the initial turbidity when the mulchic acid regulates pH.There is a positive relationship between the difference between the quantity and the turbidity.Examples filter the slurry after treatment, and take the filtering solution to ...

Embodiment 2

[0044] Use lipase to control the secondary glue in white water.

[0045] Take 200ml of old news paper DIP pulp and OCC pulp machine white water samples, and process it under different lipase added.The lipidase live 20000U / ml, the pH value is 8.0, the additional amount is 0.001 to 0.5%of the weight of the white water sample of DIP and OCC pulp machines, the temperature is 20-60 ° C, and the time is 60-120min.

[0046] After processing the paper machine, the white water of the paper machine is centrifuged 15 minutes under 2000r / min to remove the small fiber and other components; test the demand and turbidity of the cationic cation of white water after the centrifugation, and then use the sulfuric acid to adjust the pH to the turbidity to determine it.Differences of turbidity.The test results are as follows when the amount of enzymes is 0.001%, 0.05%, and 0.5%is calculated as follows.

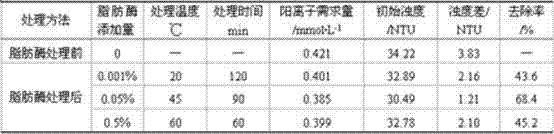

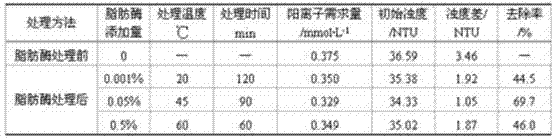

[0047] The results are shown in Table 3. Table 4:

[0048] Table 3 Lipse processed DIP Paper Paper...

Embodiment 3

[0054] Use lipase control mechanical slurry production process in the process of production.

[0055] Take 30g of dried dry ponytail TMP pulp and dilute 3%thickness. Under different lipase adding, the slurry is processed.The hydrolysis rate is greater than 96%, the liponase transfers, the lipid synthesis rate is less than 2%.

[0056] For the processing of slurry filtering, take the filtering solution to remove small fibers and other components by centrifugal fiber at 2000r / min; test the demand and turbidity of cationic ions after centrifugal water -like, and then use sulfuric acid to regulate the turbidity and then measure it. Calculate, calculateDifferences before and after pH adjustment.The test results are as follows when the amount of enzymes is 0.001%, 0.05%, and 0.5%is calculated as follows.

[0057] The result is shown in Table 5:

[0058] Table 5 The removal effect of the secondary adhesive in ponytail TMP slop

[0059]

[0060] Resin substances in mechanical slurry are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com