Metal nano electroplating technology

An electroplating process and metal nanotechnology, applied in electrolytic coatings, coatings, etc., can solve problems such as difficulty in dispersion, and achieve the effects of overcoming agglomeration, good binding force, and strong high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a metal nano-electroplating process with low porosity and good mechanical comprehensive properties of the electroplating layer, good manufacturability, simple equipment and low energy consumption.

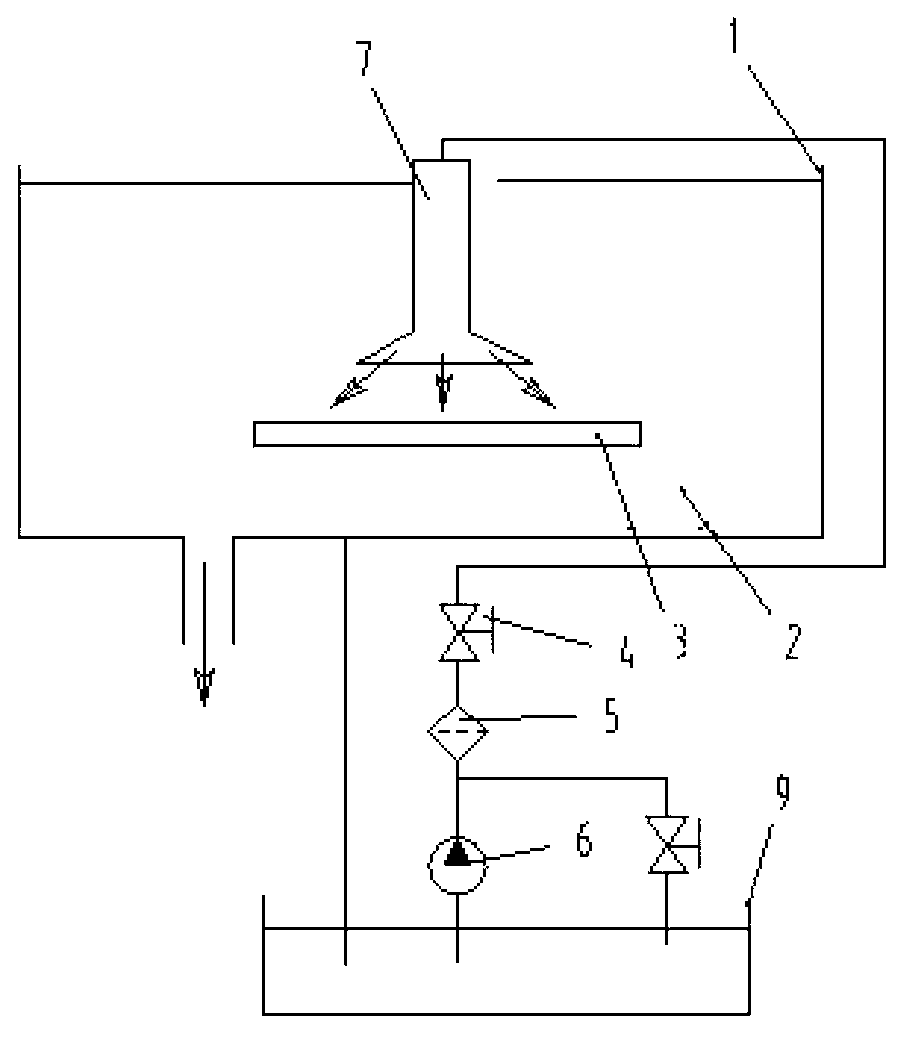

[0016] The device for electroplating process such as figure 1 shown. The mandrel 3 is made of No. 45 steel, placed in the electroplating tank 1, and the electroplating tank 1 is filled with the electroplating solution 2 from time to time. The electroplating solution in the liquid storage tank 9 is circulated and supplied by the pump 6 to keep the electroplating solution continuously updated. The upper part of the mandrel 3 is provided with the nozzle 7 , and the particle flow is sprayed onto the upper surface of the mandrel 3 through the nozzle 7 .

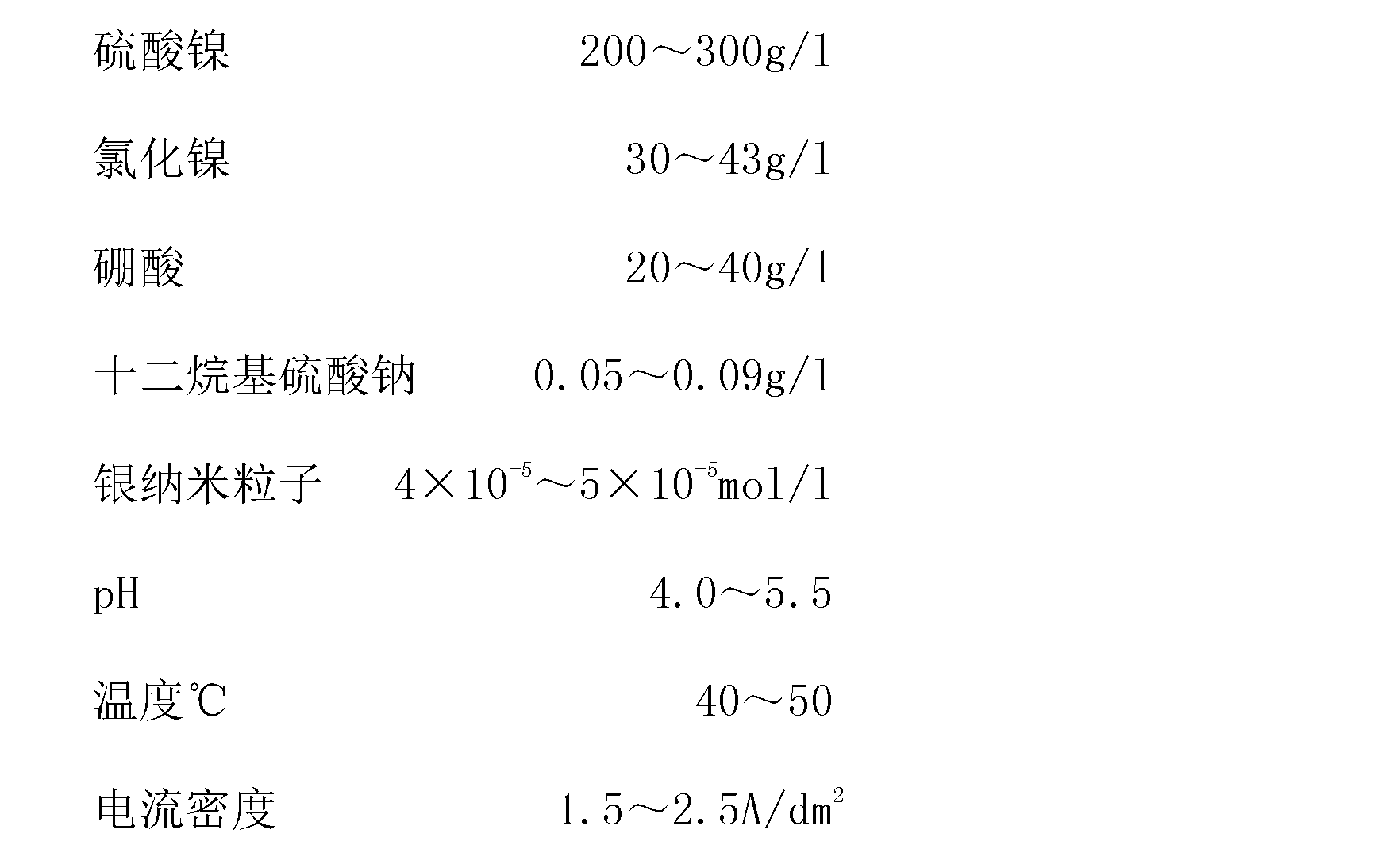

[0017] The formula and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com