Graphite plate, reaction chamber with graphite plate, and substrate heating method

A graphite disk and substrate technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of low yield and low uniformity of epitaxial chips, achieve improved uniformity, eliminate heating The effect of unevenness and uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

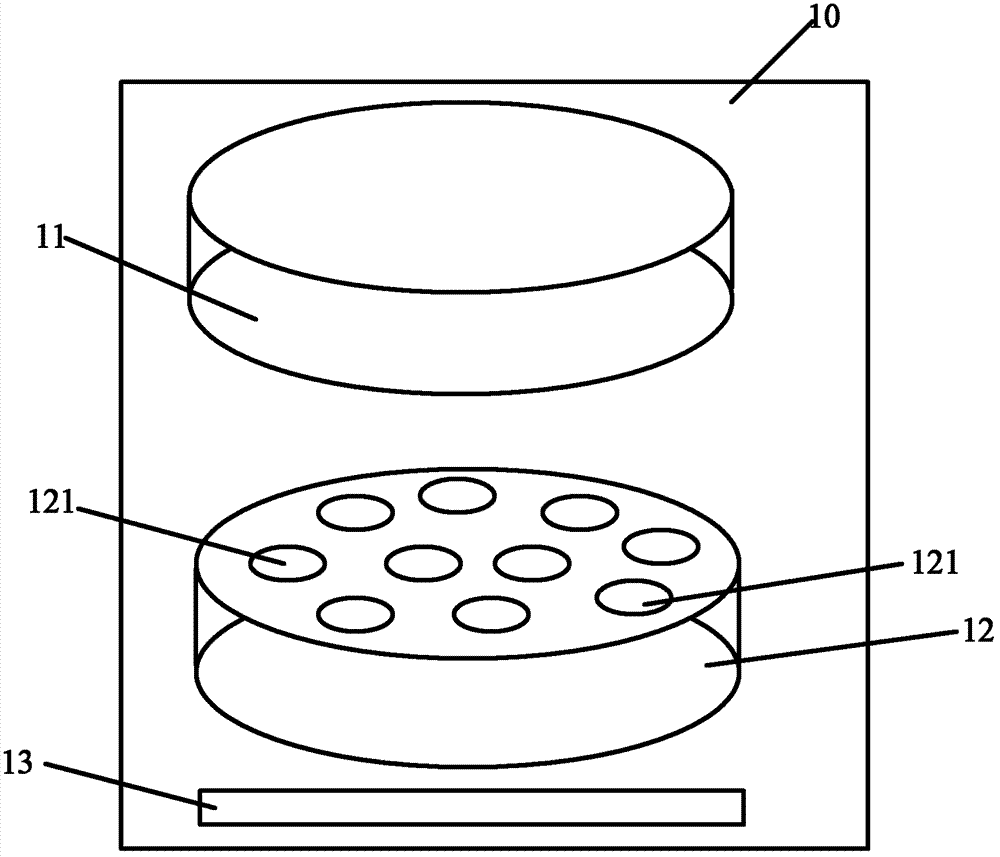

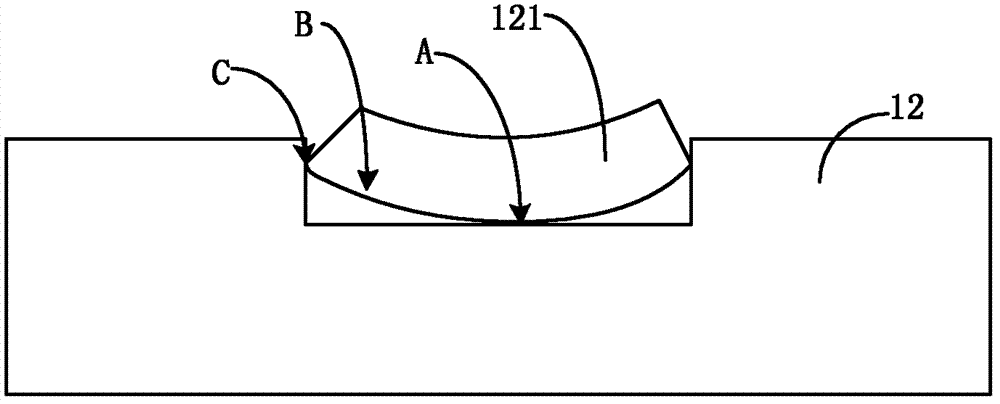

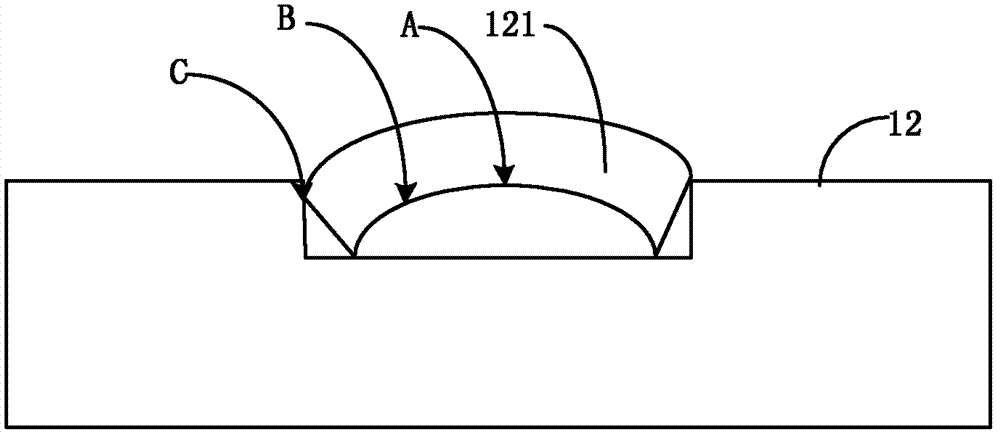

[0045] The uniformity of the chemical vapor deposition process in the prior art is not high, and the yield rate of the epitaxial chip is low. After research by the inventors, it is found that the epitaxial material layer formed on the substrate after the chemical vapor deposition process is not uniform due to uneven heating of the substrate (there is a temperature difference at each point of the substrate). One of the causes of uneven heating of the substrate is that the substrate is warped due to stress during the chemical vapor deposition process. Usually the substrate is placed in a graphite disk, and the two are in contact. The graphite disk can heat the substrate in two ways: heat conduction and heat radiation. When the substrate is warped and deformed, the distances between the points where the substrate should be in contact with the graphite disk and the graphite disk are different, so that the substrate is heated unevenly. Furthermore, the inventors also found that, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com