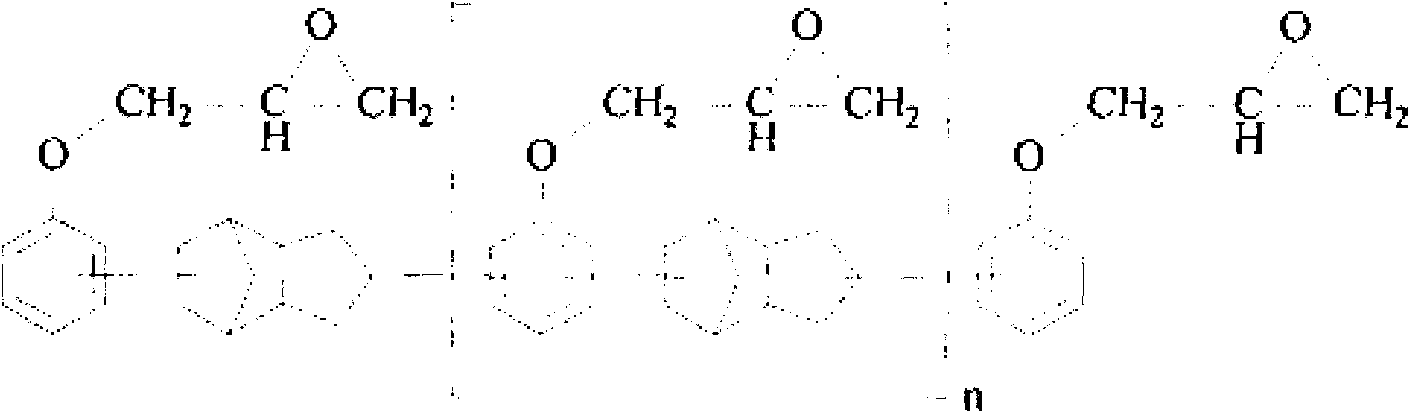

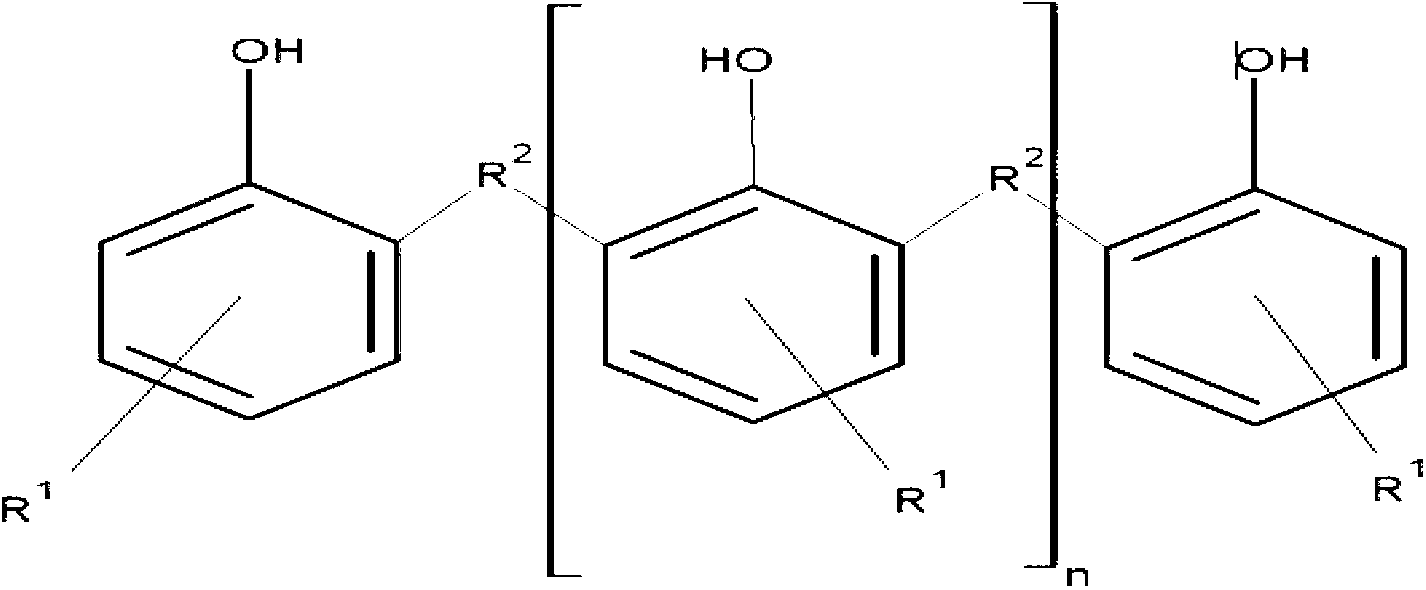

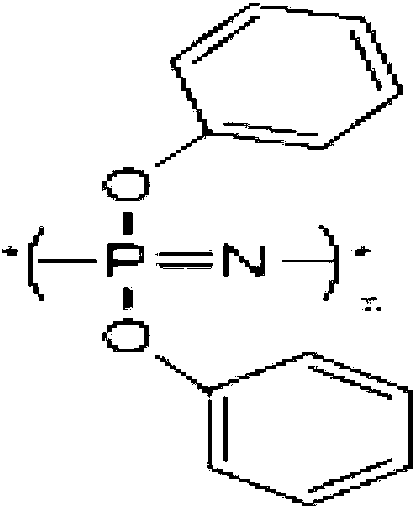

Halogen-free low dielectric epoxy resin composition

A technology of epoxy resin and composition, which is applied in the field of epoxy resin composition of laminates, can solve the problems of poor heat resistance and poor processability, and achieve the effects of low dielectric constant, high heat resistance and increased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific examples of the present invention to further describe the present invention, but the present invention is not limited to these examples.

[0031] The sources of all raw material components in the following examples are shown in Table 1, and the formulations of the epoxy resin compositions of Examples 1-6 are shown in Table 2.

[0032] Table 1

[0033]

[0034] Table 2

[0035]

[0036] The copper clad substrate is prepared through the following steps in sequence:

[0037] (1) Prepare the glue solution according to the formula in Table 2: add the components of the formula amount into the batching container at about 40°C, and stir evenly;

[0038] (2) Gluing: Bake the adhesive cloth soaked in the above glue (i.e. electronic grade fiber glass cloth) in an oven to make a prepreg, the baking temperature is 200-300°C, and the prepreg gluing speed is 8-12m / min;

[0039] (3) Hot pressing: After combining the cut prepreg and the electrolytic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com