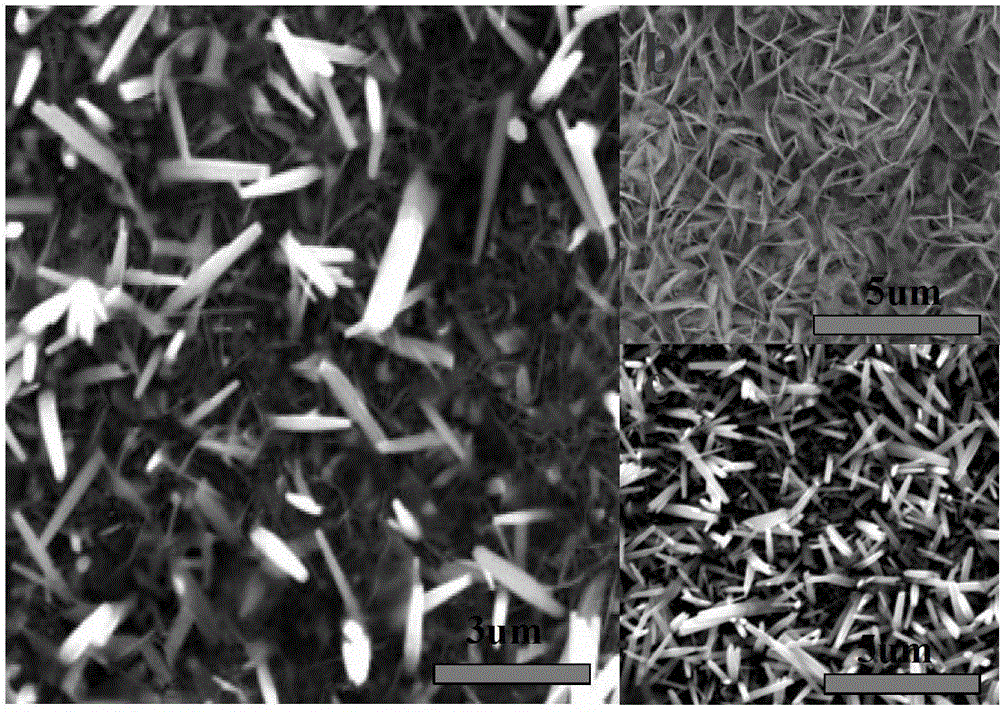

Preparation method of material adopting ZnO nanorod and ZnO nanosheet composite structure

A technology of nanosheet and composite structure, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that it is difficult to effectively improve the specific surface area of the photoanode, limit the amount of dye loading, and the photoelectric conversion of the battery Low efficiency and other issues, to achieve the effect of improving photoelectric replacement efficiency, uniform composite structure morphology, and high charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Clean the FTO substrate: ultrasonically clean with acetone for 10 minutes, then ultrasonically clean with deionized water and absolute ethanol for 20 minutes each. Remove the contamination layer on the FTO surface, and finally get a clean FTO substrate, which is dried at 60°C in a drying oven. The resistivity of the ultrapure water used must be above 16 Ω·cm;

[0014] 2. Configure 0.025M Zn (NO 3 ) 2 Put 20ml of the aqueous solution in a glass beaker and stir it until it is completely dispersed.

[0015] 3. Prepare 20ml of 0.025M urotropine aqueous solution in a glass beaker, stir magnetically until completely dispersed.

[0016] 4. Pour the urotropine aqueous solution in step 3 into the Zn(NO 3 ) 2 In the aqueous solution, continue to stir until uniformly dispersed.

[0017] 5. Carry out hydrothermal synthesis reaction: put the cleaned FTO substrate and a piece of aluminum oxide sheet in step 1 into a 50ml high-pressure reactor at the same time, and pour the m...

Embodiment 2

[0022] 1. Clean the FTO substrate: ultrasonically clean with acetone for 10 minutes, then ultrasonically clean with deionized water and absolute ethanol for 20 minutes each. Remove the contamination layer on the FTO surface, and finally get a clean FTO substrate, which is dried at 60°C in a drying oven. The resistivity of the ultrapure water used must be above 16 Ω·cm;

[0023] 2. Configure 0.022M ZnNO 3. Put 20ml of the aqueous solution in a glass beaker and stir it until it is completely dispersed.

[0024] 3. Configure 20ml of 0.023M urotropine aqueous solution in a glass beaker, stir magnetically until completely dispersed.

[0025] 4. Pour the urotropine aqueous solution in step 3 into the ZnNO in step 2 3. In the aqueous solution, continue to stir until uniformly dispersed.

[0026] 5. Carry out hydrothermal synthesis reaction: put the cleaned FTO and a piece of alumina film in step 1 into a 50ml high-pressure reactor at the same time, and pour the mixed solution obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com