Method for removing boron in polycrystalline silicon

A polysilicon and silicon liquid technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high consumption of slag-forming agents and expensive high-temperature plasma equipment, reducing silicon loss, reducing boron removal effect, and increasing effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

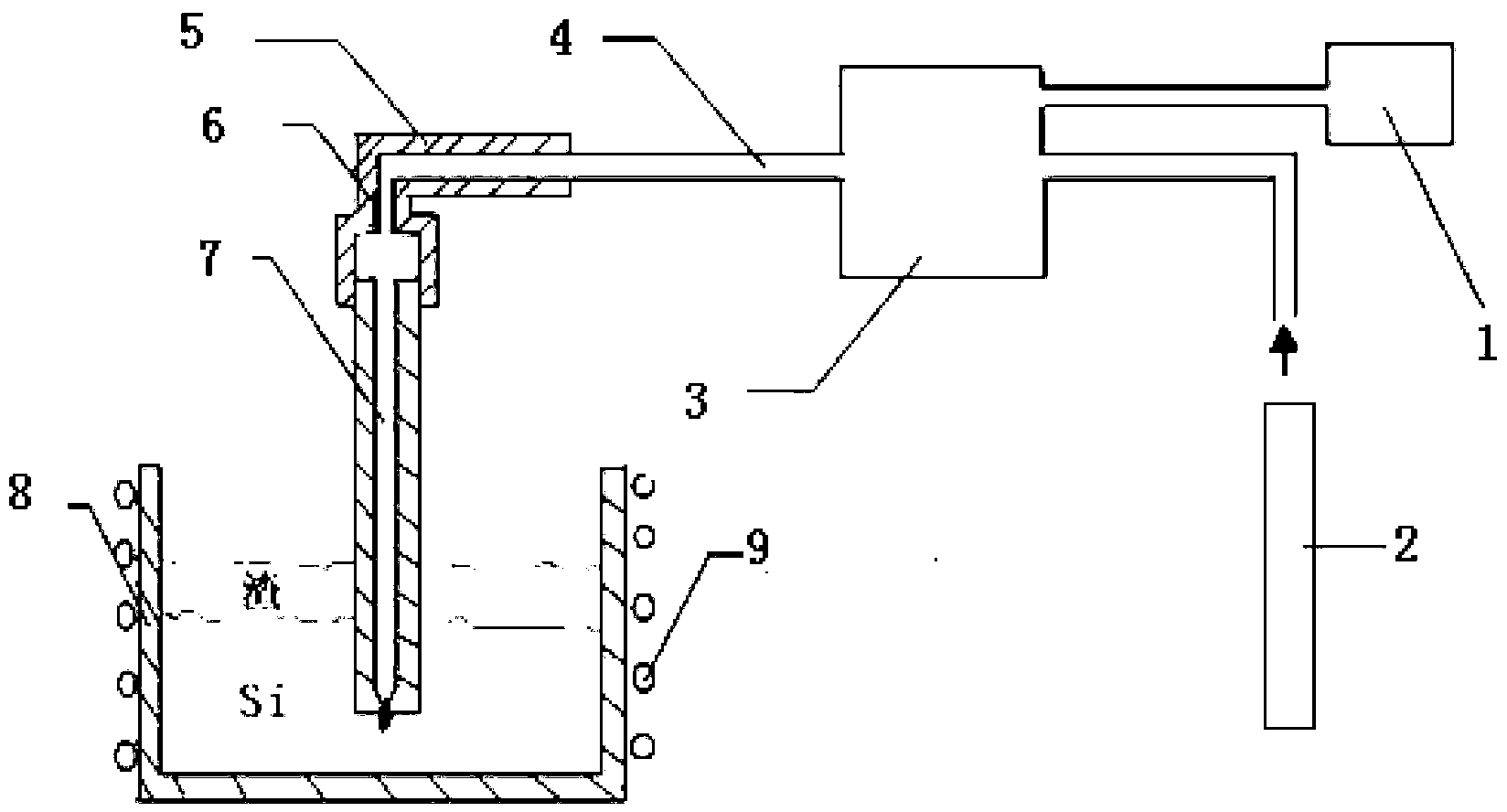

Image

Examples

Embodiment 1

[0036] Weigh 50 kg of raw material industrial silicon, heat the silicon block into a graphite crucible of an intermediate frequency induction furnace, and melt it into a silicon liquid, keeping the temperature at 1500 ° C.

[0037] Weigh the composite slag forming agent NaCl~KCl~SiO2, by weight percentage, of which NaCl is 20%, KCl is 20%, SiO2 is 60%, and the mass ratio of composite slag agent to industrial silicon is 0.6:1, that is, 30kg.

[0038] Put the powdery composite slagging agent into the silicon liquid, continue heating to completely melt the slagging agent, and keep the temperature of the silicon liquid at 1500°C,

[0039] Preheat the graphite rod with the ventilation channel, insert the ventilation rod into the above-mentioned silicon liquid after preheating and start to pass oxygen, the gas flow rate of the oxygen is 5L / min, and the ventilation reaction time is 25min.

[0040] Turn on the high-voltage plasma generator, ionize part of the oxygen in the pipeline in...

Embodiment 2

[0043] Weigh 50 kg of industrial silicon as raw material, heat the silicon block in a graphite crucible of an intermediate frequency induction furnace, and melt it into a silicon liquid, keeping the temperature at 1700°C.

[0044] Weigh the composite slagging agent NaCl~KCl~SiO 2 , by weight percentage, where NaCl is 25%, KCl is 25%, SiO2 is 50%, and the mass ratio of composite slagging agent to industrial silicon is 0.8:1, that is, 40kg.

[0045] Put the powdery composite slagging agent into the silicon liquid, continue heating to completely melt the slagging agent, and keep the temperature of the silicon liquid at 1700°C.

[0046] Preheat the graphite rod with the ventilation hole, insert the ventilation rod into the above-mentioned silicon liquid after preheating and start the oxygen flow, the gas flow rate of the oxygen is 10L / min, and the ventilation reaction time is 30min.

[0047] Turn on the high-voltage plasma generator, ionize part of the oxygen in the pipeline into o...

Embodiment 3

[0050] Weigh 50 kg of raw industrial silicon, put the silicon material into a graphite crucible of an intermediate frequency induction furnace, heat it, and melt it into silicon liquid, keeping the temperature at 1800°C.

[0051] Weigh the composite slagging agent NaCl~KCl~SiO 2 , by weight percentage, of which NaCl is 30%, KCl is 30%, SiO2 is 40%, and the mass ratio of composite slagging agent to industrial silicon is 1:1, that is, 50kg.

[0052] Put the powdery composite slagging agent into the silicon liquid, continue heating to completely melt the slagging agent, and keep the temperature of the silicon liquid at 1800°C.

[0053] Preheat the graphite rod with the ventilation channel, insert the ventilation rod into the above silicon liquid after preheating, and start to ventilate the gas. The gas flow rate of the oxygen is 12L / min, and the ventilation reaction time is 35min.

[0054] Turn on the high-voltage ion generator, ionize part of the oxygen in the pipeline into oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com