Hydrogen-production photocatalyst MoS2/ZnIn2S4 and preparation method thereof

A photocatalyst, znin2s4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as high cost and complex production process, and achieve improved hydrogen production performance, efficient reaction, effective Conducive to the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Composite photocatalyst MoS with efficient and stable photocatalytic hydrogen production 2 / ZIS preparation

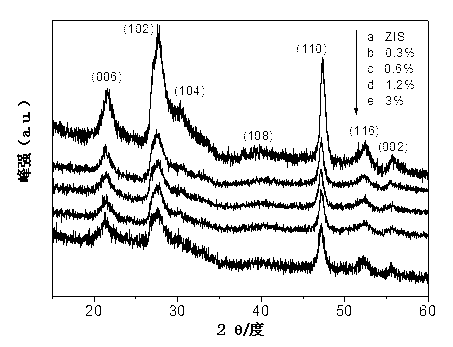

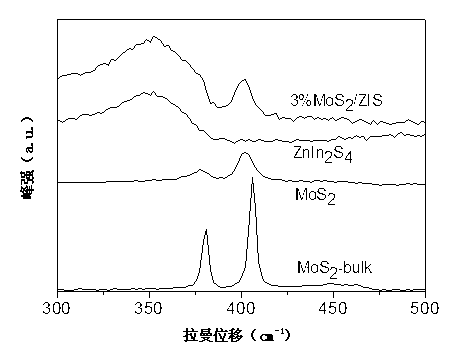

[0024] First prepare ZnIn 2 S 4 : 0.136g ZnCl with a molar ratio of 1:2:2 2 , 0.586g InCl 3 4H 2 O and 1.5 g of thioacetamide (TAA) were added to 70 ml of H 2 In O, a transparent solution was obtained after stirring for 2 hours, and the solution was transferred to a 100ml hydrothermal kettle, and reacted at 120°C for 10 hours to obtain it; then the MoS 2 The precursor ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ))) wets the ZnIn obtained above 2 S 4 , dried in a vacuum oven at 60°C to obtain the precursor (NH 4 ) 2 MoS 4 / ZIS, place the sample in H2 Calcined at 350°C for 3h in S atmosphere to obtain MoS 2 / ZIS photocatalyst; MoS 2 The amount of loading varies from 0.3wt% to 5wt%. figure 1 Demonstrating the present invention with different contents of MoS 2 / X-ray diffraction (XRD) pattern of ZIS, all diffraction peaks belong to ZnIn 2 S 4 Dif...

Embodiment 2

[0026] MoS 2 The precursor of (NH 4 ) 2 MoS 4 in H 2 Calcined at 350 °C for 3 h in S atmosphere to obtain MoS 2 as comparison.

Embodiment 3

[0028] Composite photocatalyst MoS 2 / ZIS and ZnIn 2 S 4 And the photocatalytic hydrogen production performance comparison of 1wt%Pt / ZIS under visible light.

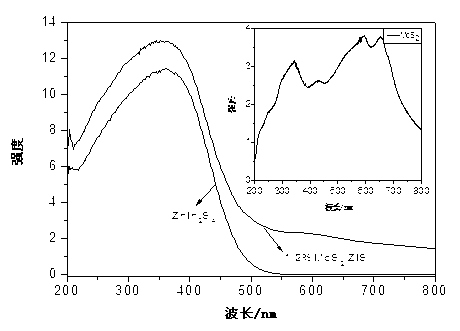

[0029] The resulting composite photocatalyst MoS 2 / ZIS is used for photolysis of water to produce hydrogen, weigh 50mg sample and add to 100ml containing 10.33g Na 2 S and 6.3g Na 2 SO 3 In the aqueous solution, after the photocatalytic hydrogen production system is evacuated, the light source is turned on for photocatalytic hydrogen production. The amount of photocatalytic hydrogen production was detected by chromatography (Fuli, China, TCD, argon as carrier gas, 0.5nm molecular sieve column). Composite photocatalyst MoS of the present invention 2 / ZIS and ZnIn 2 S 4 and 1wt% Pt / ZIS photocatalytic hydrogen production performance comparison under visible light as follows Figure 4 . It can be seen from the figure that 1.2wt% MoS 2 The hydrogen production rate of ZIS is about that of ZnIn 2 S 4 12 times th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com