Preparation method for solid phase microextraction recognizable adsorption coating

A recognition and coating technology, applied in the field of sample pretreatment in analytical chemistry, can solve problems such as interference, and achieve the effect of improving the ability to identify adsorption, improve the ability to identify adsorption, and increase the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

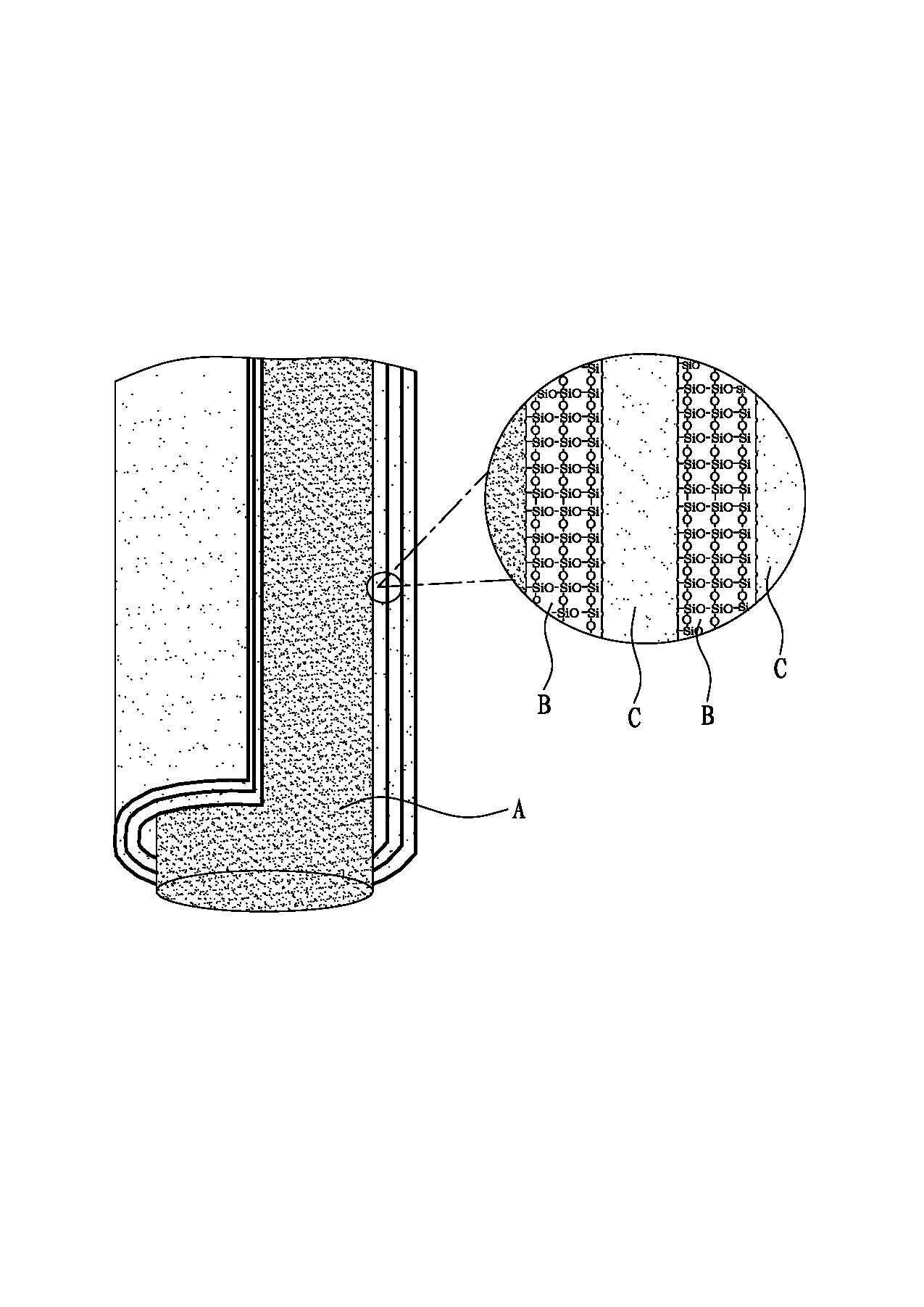

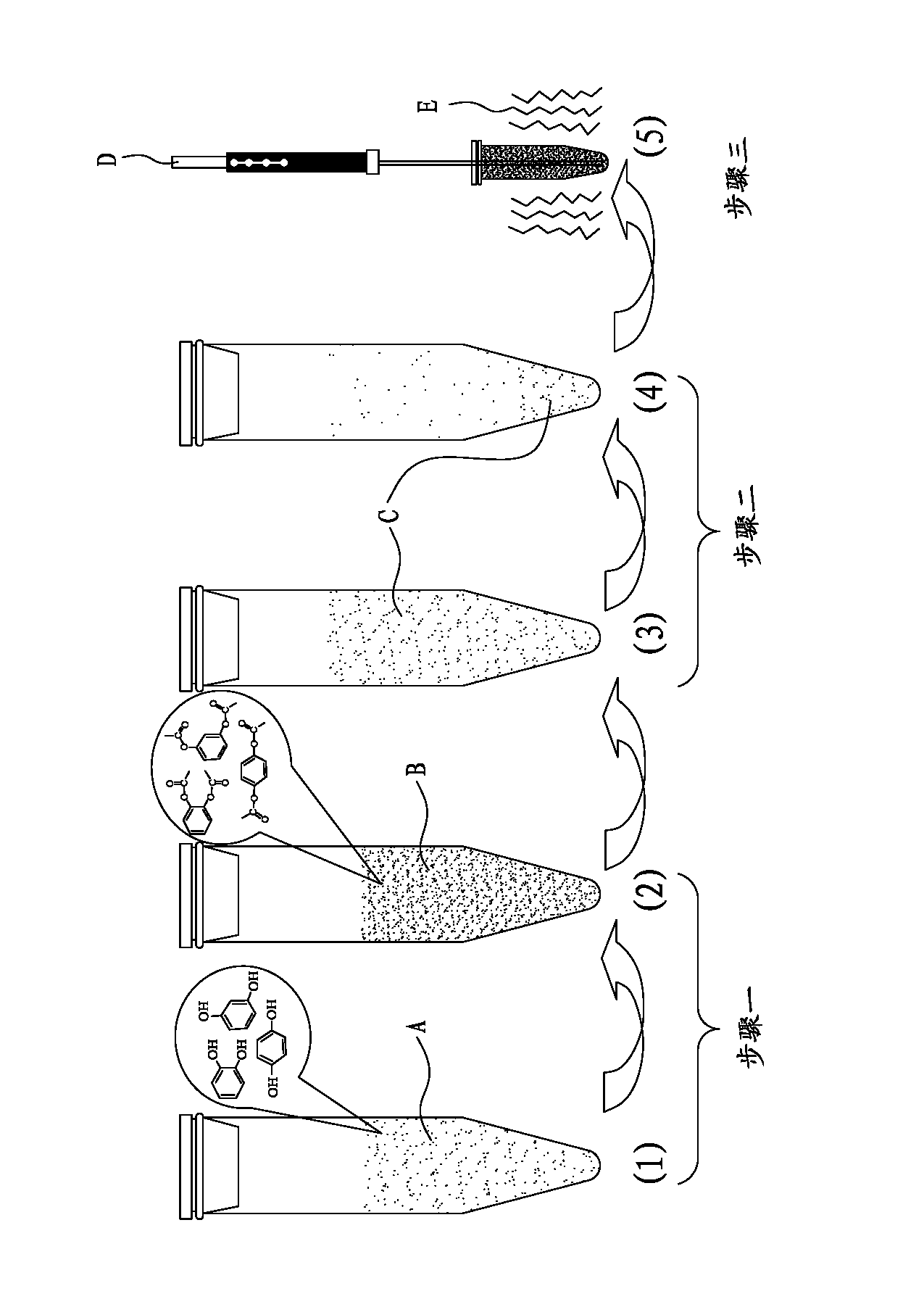

[0031] Cooperate figure 1 , 2 As shown, the present invention discloses a layer-by-layer alternating structure SiO 2 / Preparation method of carbon nanotube-supported molecularly imprinted membrane (CNTs-MIP) solid-phase microextraction adsorption coating, the specific contents include:

[0032] Step 1. Pretreatment of supporting stainless steel wire

[0033] The 1.5 cm end of the supporting stainless steel wire fiber was corroded with hydrofluoric acid for 3 h, and then washed with deionized water, methanol, acetone, and chloroform in sequence, and left to dry at room temperature.

[0034] Step 2. Activation of carbon nanotubes (CNTs)

[0035] Add CNTs to the mixed solution of concentrated sulfuric acid and concentrated nitric acid ( V : V =3:1), ultrasonically disperse and acidify at 70°C for 3 h, so that the CNTs can be charged with -OH, -COOH, -CH 3 Such activated groups are beneficial to the coating of organic polymers.

[0036] Step 3, SiO 2 Preparation of sol so...

Embodiment

[0045] Embodiment (dimethyl phthalate layer alternating structure SiO 2 / Preparation and application of SPME recognition adsorption coating of CNTs-MIP)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com