Preparation method of remote explosionproof high-power plasma catalyzed carbon dioxide

A technology for catalyzing carbon dioxide and plasma, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reporting, high operating costs, and large investment in technology implementation, and achieve lower conversion temperature, less equipment investment, The effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

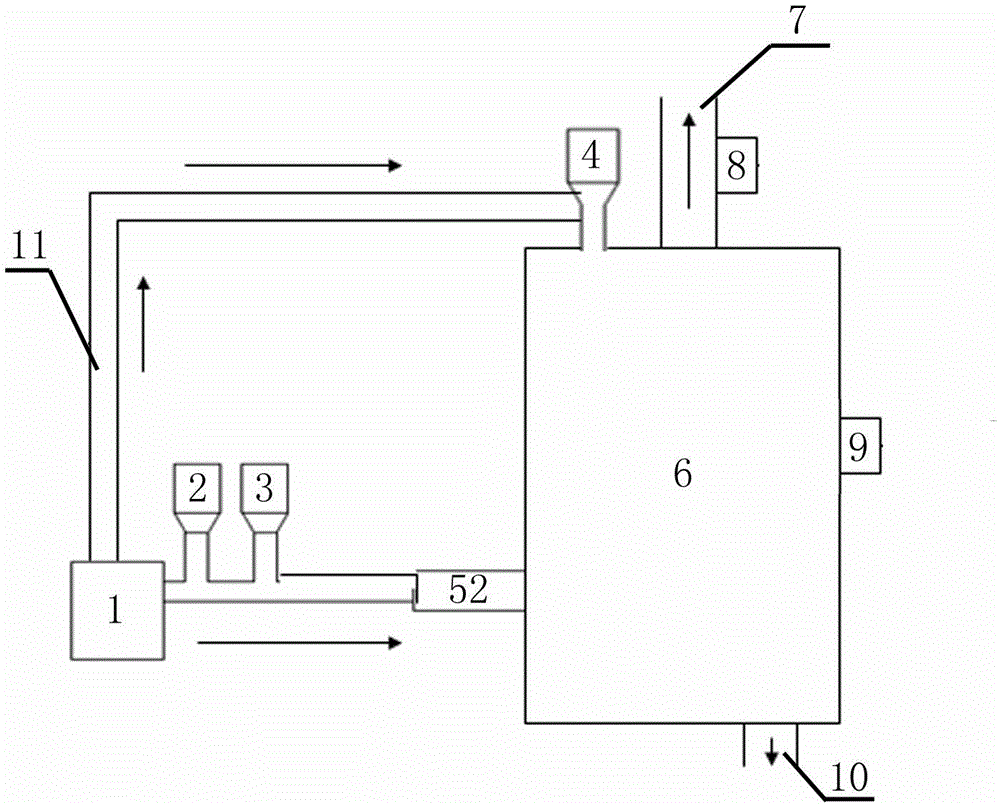

[0032] Embodiment 1: The preparation method of remote explosion-proof remote explosion-proof high-power plasma catalytic carbon dioxide is characterized in that comprising the following steps:

[0033] 1) The active agent sensor weighing device, the catalyst sensor weighing device, and the pulverized coal sensor weighing device respectively transport the active agent, catalyst, and coal powder into the pipeline according to the metering ratio, and the CO2 gas tank delivers carbon dioxide gas into the pipeline; The active agent, catalyst, and coal powder are blown through the 500W-8000KW plasma catalyst and then enter the catalytic reaction furnace; the catalyst in the control process is a metal element compound, and the weight ratio of the catalyst to carbon dioxide is 0.1%, and the active agent is plant chlorophyll powder. The weight ratio of agent and carbon dioxide consumption is 0.1%;

[0034] 2) The carbon dioxide and coal in step 1) are contacted and reacted in a catalyt...

Embodiment 2

[0054] Embodiment 2: The preparation method of remote explosion-proof remote explosion-proof high-power plasma catalytic carbon dioxide is characterized in that it comprises the following steps:

[0055] 1) The active agent sensor weighing device, the catalyst sensor weighing device, and the pulverized coal sensor weighing device respectively transport the active agent, catalyst, and coal powder into the pipeline according to the metering ratio, and the CO2 gas tank delivers carbon dioxide gas into the pipeline; The active agent, catalyst, and coal powder are blown through the 500W-8000KW plasma catalyst and then enter the catalytic reaction furnace; the catalyst is a metal element compound, and the weight ratio of the catalyst to carbon dioxide is 5%, the active agent is plant chlorophyll powder, the active agent and carbon dioxide The weight ratio of consumption is 5%;

[0056] 2) The carbon dioxide and coal in step 1) are contacted and reacted in a catalytic reactor under t...

Embodiment 3

[0076] Embodiment 3: The preparation method of remote explosion-proof remote explosion-proof high-power plasma catalytic carbon dioxide is characterized in that it comprises the following steps:

[0077] 1) The active agent sensor weighing device, the catalyst sensor weighing device, and the pulverized coal sensor weighing device respectively transport the active agent, catalyst, and coal powder into the pipeline according to the metering ratio, and the CO2 gas tank delivers carbon dioxide gas into the pipeline; The active agent, catalyst, and coal powder are blown through the 500W-8000KW plasma catalyst and then enter the catalytic reaction furnace; the catalyst is a metal element compound, and the weight ratio of the catalyst to carbon dioxide is 3%, the active agent is plant chlorophyll powder, the active agent and carbon dioxide The weight ratio of consumption is 3%;

[0078] 2) The carbon dioxide and coal in step 1) are contacted and reacted in a catalytic reactor under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com