Low-noise switching mode power supply transformer and low-noise switching power supply

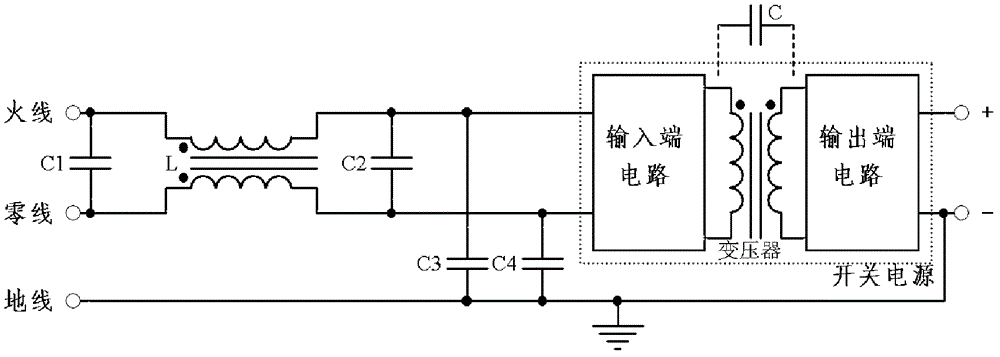

A low-noise switching, switching power supply technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, output power conversion device, etc. and other problems to achieve the effect of suppressing common mode interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

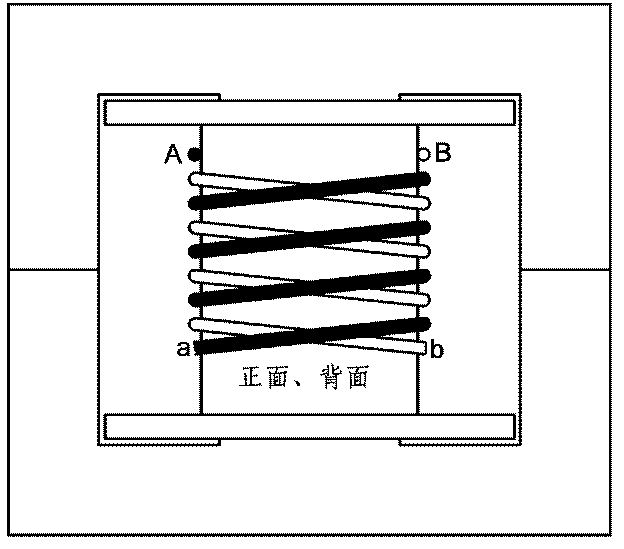

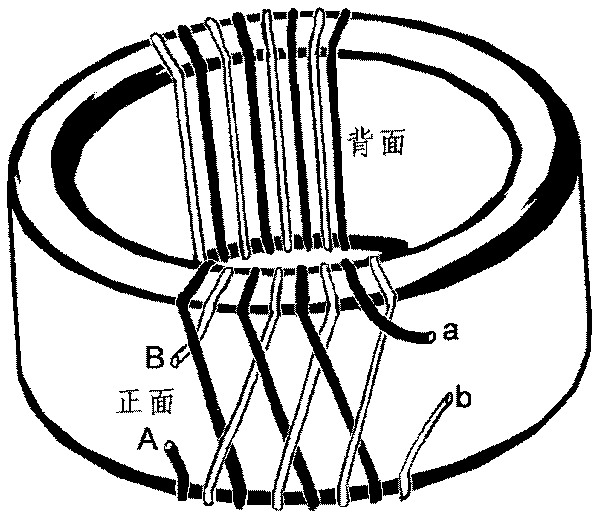

[0024] see Figure 4 , The half-bridge switching power supply includes a transformer, half-bridge drive tubes Q1, Q2, diodes D1, D2 and capacitor C. The primary and secondary windings each have two symmetrical windings with opposite ends. The A terminal of the primary winding is connected between the half-bridge drive tubes Q1 and Q2, the a terminal is connected to the b terminal and then grounded through the capacitor C; the B terminal of the primary winding is suspended, and the b terminal is connected to the a terminal; one end of the secondary winding is connected, The other end is two opposite ends, one of which is connected to the diode D1, and the other is connected to the diode D2. Diodes D1 and D2 are used for full wave rectification. At this time, the a-end and b-end of the primary winding are AC grounded through the capacitor C, and there is no high-frequency common-mode voltage to the earth; the high-frequency common-mode voltage distribution from A-end to a-end ...

Embodiment 2

[0026] see Figure 5 , The push-pull switching power supply includes a transformer, push-pull drive tubes Q1, Q2, diodes D1, D2. The primary and secondary windings each have two symmetrical windings with opposite ends. The push-pull drive tubes Q1 and Q2 are turned on in turn. Terminal A of the primary winding is connected to push-pull drive tube Q2, terminal B is connected to push-pull drive tube Q1, and terminals a and b are connected to a DC power supply VCC. One end of the secondary winding is connected, and the other end is two opposite ends, wherein one opposite end is connected to the diode D1, and the other end is connected to the diode D2. Diodes D1 and D2 are used for full wave rectification. At this time, the a-terminal and b-terminal of the primary winding are connected to VCC, and there is no high-frequency common-mode voltage to the ground; the high-frequency common-mode voltage distribution generated at any position from A-terminal to a-terminal, B-terminal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com