Method for fast evaluating high temperate member residual service life on spot

A life and component technology, applied in the field of on-site rapid evaluation of remaining life of high-temperature components based on hardness testing, can solve problems such as industrial production interruption, high cost, and large economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

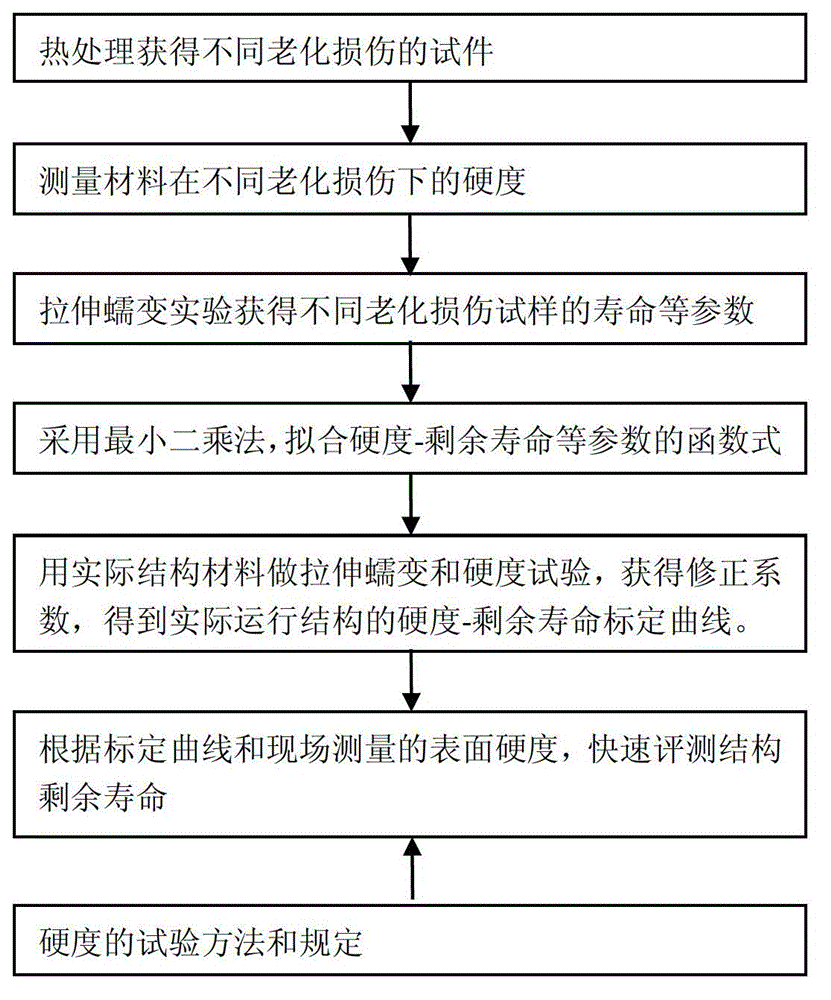

[0060] like figure 1 Shown is the flow chart of the on-site rapid evaluation method for the remaining life of high-temperature components based on hardness detection of the present invention, including the following steps:

[0061] (1) First determine the hardness testing instrument, and make high temperature test samples

[0062] For example, a Vickers hardness measuring instrument is used as a laboratory testing instrument. Determine the heating temperature of the test piece according to the national standard and the actual working temperature of high-temperature components. For example, the working temperature fluctuates above 735°C, and the test temperatures can be 685°C, 735°C and 800°C.

[0063] (2) Determine the number of tests for each group in the laboratory according to the temperature

[0064] Make hardness samples according to the national standard, and conduct at least 2 tests for each test condition. Because the higher the temperature, the more scattered the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com