Radial inclination compressive strength test device for round-section concrete-filled steel tube

A technology for concrete-filled steel tubular (CFST) and strength testing, which is applied in the direction of applying stable tension/compression to test the strength of materials. offset, reducing equipment requirements, eliminating the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

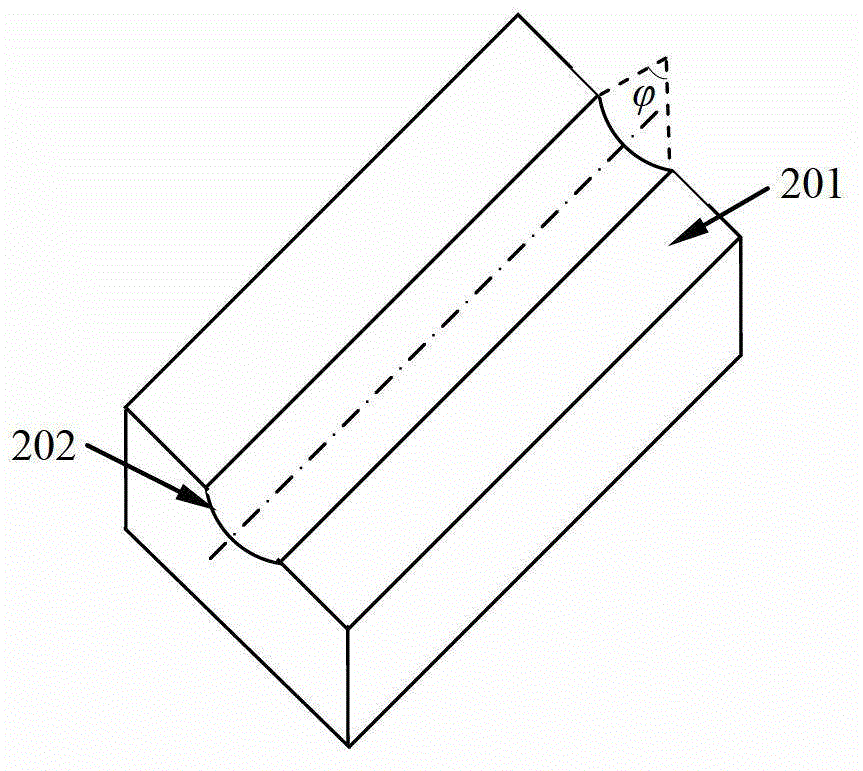

[0032] The present invention provides a test device for radially inclined compressive strength of circular cross-section concrete filled steel tubes. The specific implementation of the present invention will be further described below in conjunction with the examples and accompanying drawings.

[0033] figure 1 It is an embodiment of the present invention, a schematic diagram of a test device for testing the strength of a circular section concrete filled steel tube specimen under radially inclined compression.

[0034] The angle between the circular section concrete filled steel pipe 5 to be tested and the loading rod 6 is 45°, and the angles α and β between the inclined plane 10 and the inclined plane 11 of the main steel base 1 and the horizontal direction are 45° and 45° (90°) respectively. °-45°), to ensure that the loading bar 6 is in a vertical position after the circular section concrete filled steel tube 5 to be tested is placed. The width of the inclined plane 10 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com