Method for assembling novel substructure module type preformed assembled frame structure

A frame structure, prefabricated assembly technology, applied in infrastructure engineering, building construction, construction, etc., can solve the problems of too many on-site assembly nodes, poor safety performance, no operability, etc., to simplify design and production. Process, avoidance safety and quality, good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

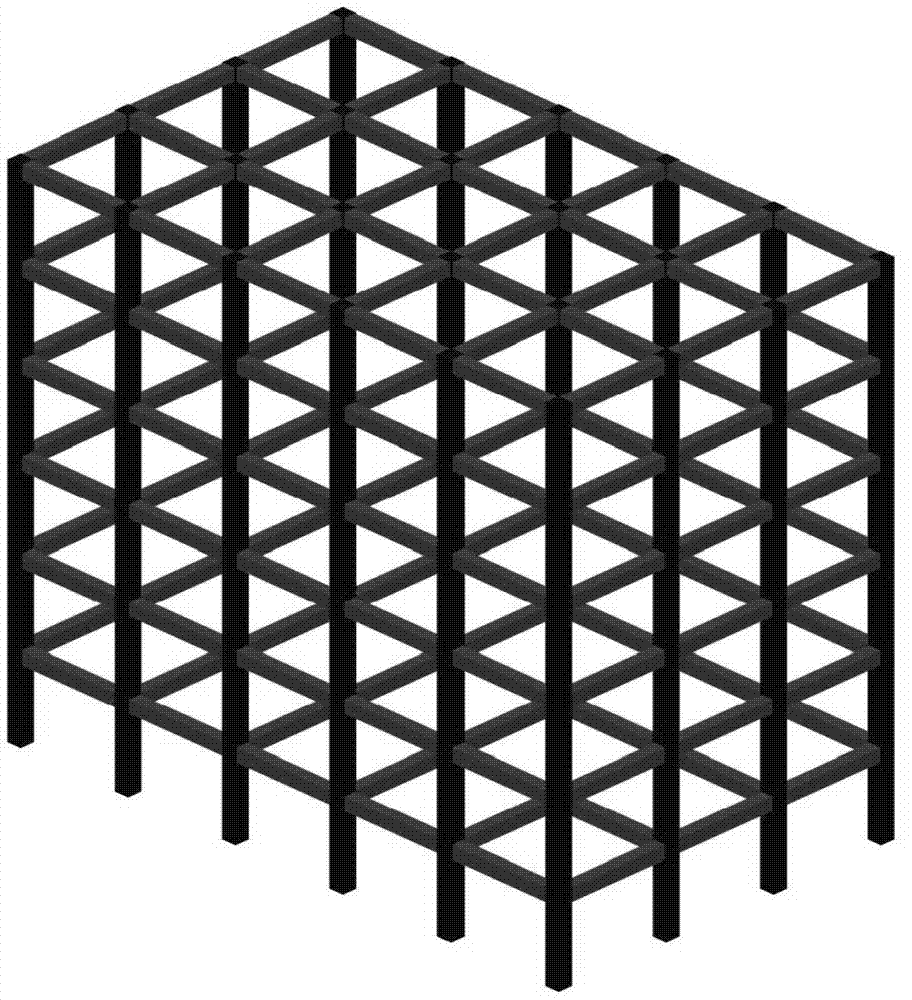

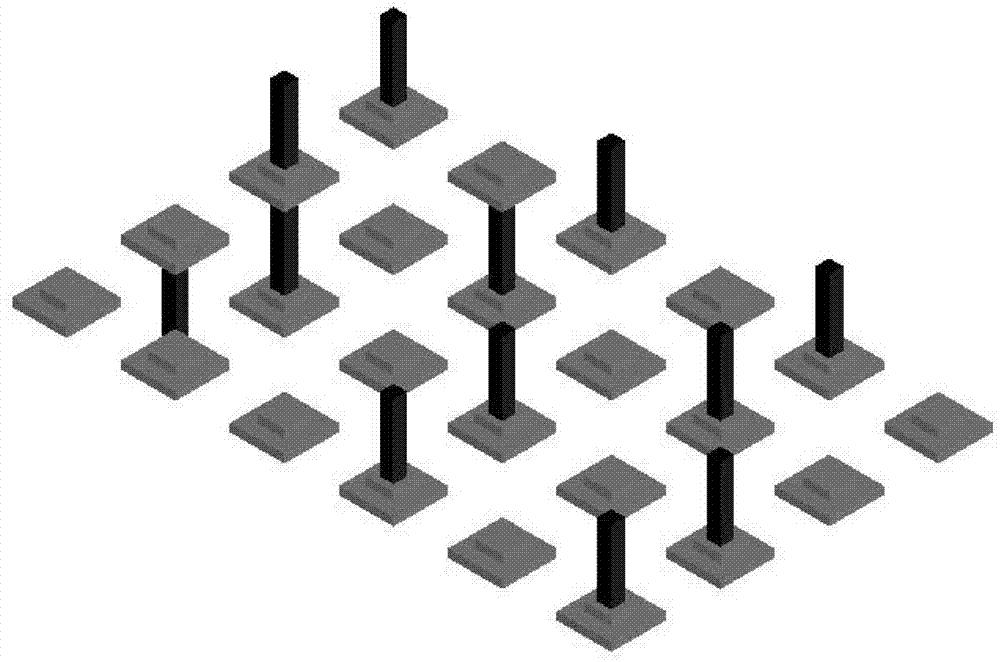

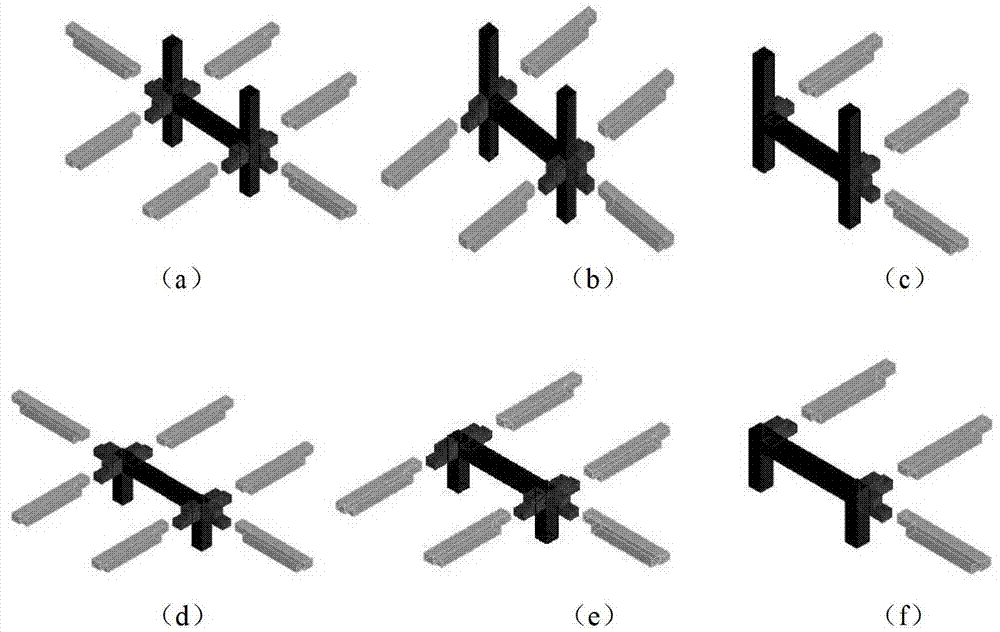

[0031] The patent of the present invention proposes a house assembly construction method based on a large prefabricated plane frame substructure, and its specific implementation process and method will be further described in conjunction with the accompanying drawings.

[0032] A novel substructure modular prefabricated assembled frame structure assembly method, characterized in that: (1) The whole building structure is divided into building foundation substructure, multiple prefabricated plane frame substructures and prefabricated beam substructures by adopting the idea of substructure modules , the prefabricated plane frame substructure is a single-story, double-layer or multi-story multi-span prefabricated plane frame substructure; (2) According to the hoisting capacity of the hoisting equipment and the building layout, each The substructure or prefabricated beam substructure is used as a separate assembly unit, and the structural form of the substructure assembly unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com