Titanium alloy superplastic-forming heating device

A heating device and titanium alloy technology, applied in the field of titanium alloy superplastic forming, can solve the problems of large energy consumption, long time consumption, and low production efficiency, and achieve the effects of simple equipment structure, improved production efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

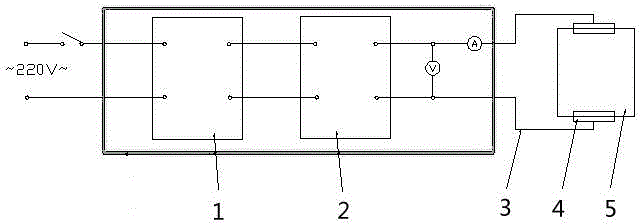

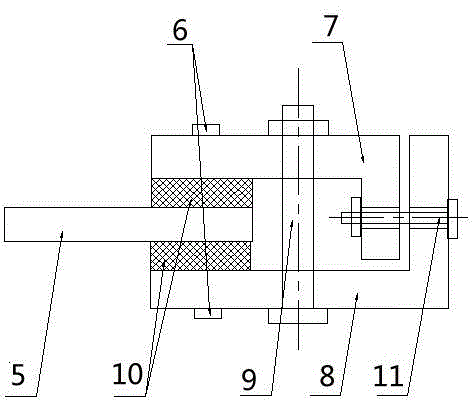

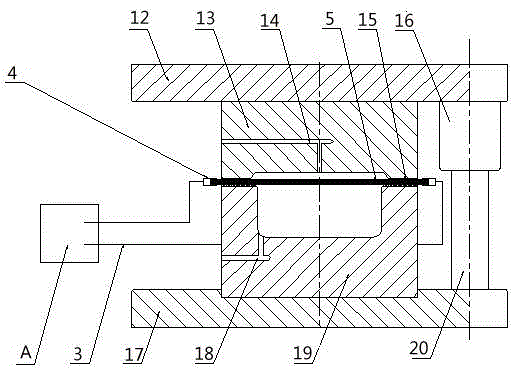

[0027] attached figure 1 It is a structural schematic diagram of a titanium alloy superplastic forming heating device of the present invention, with figure 2 It is a structural schematic diagram of the clamping device of the titanium alloy superplastic forming heating device of the present invention. In the figure, 1 is an oil-immersed induction voltage regulator, 2 is a high-current transformer, 3 is a connecting wire, 4 is a clamping device, and 5 is a clamping device. As can be seen from the figure, the titanium alloy superplastic forming heating device of the present invention includes an oil-immersed induction voltage regulator 1, a high-current transformer 2, a connecting wire 3 and a clamping device 4, and the power supply is connected to the oil-immersed induction voltage regulator 1, The output end of the oil-immersed induction voltage regulator 1 is connected to the high-current transformer 2 , and the output end of the high-current transformer 2 is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com