Color UV curable coating dedicated for oil couplings / color wheels

A curing coating and color technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as rust, economic loss, discoloration, etc., and achieve good storage stability, zero VOC emissions, and cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention uses a high-reactivity low-molecular-weight polyurethane acrylate resin with 4-6 functionalities that can improve the strength of the paint film and a medium-reactive middle-low molecular weight polyurethane acrylic acid with 2-3 functionalities that can improve the flexibility of the paint film. Ester resin is the main resin, adding reactive diluents, photosensitizers, etc. to form a film through UV light curing reaction, and is made by adding non-toxic coloring pigments, nano-powders, non-toxic anti-rust pigments, additives, and auxiliary agents.

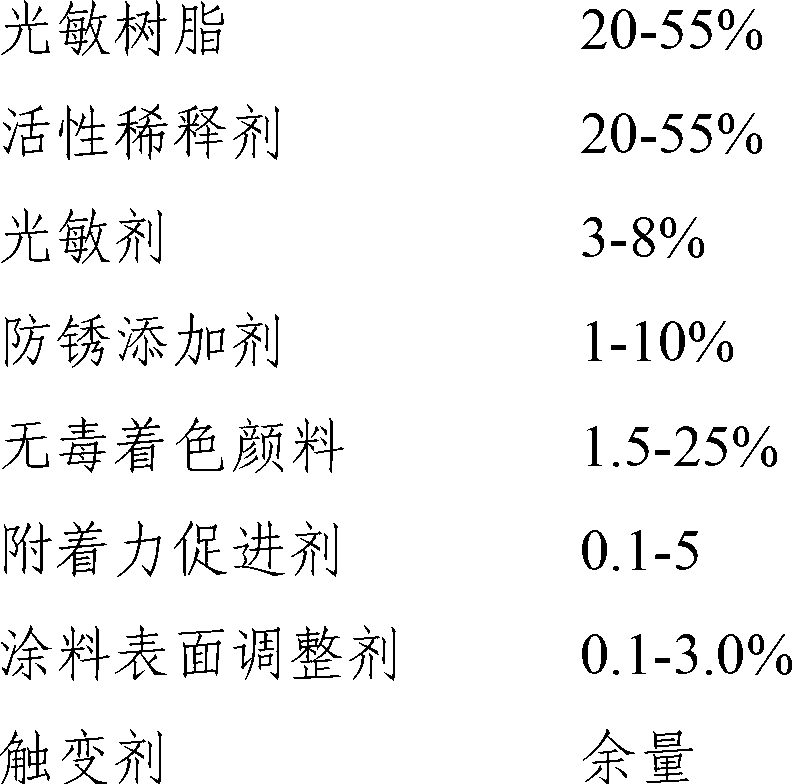

[0022] A special color UV curing coating for petroleum couplings / color rings, consisting of the following raw materials in weight percentages:

[0023]

[0024]

[0025] A kind of preparation method of the special color UV curable paint of petroleum coupling / color ring of the present invention is to put photosensitive resin, thixotropic agent, paint surface regulator, part of active diluent, anti-rust add...

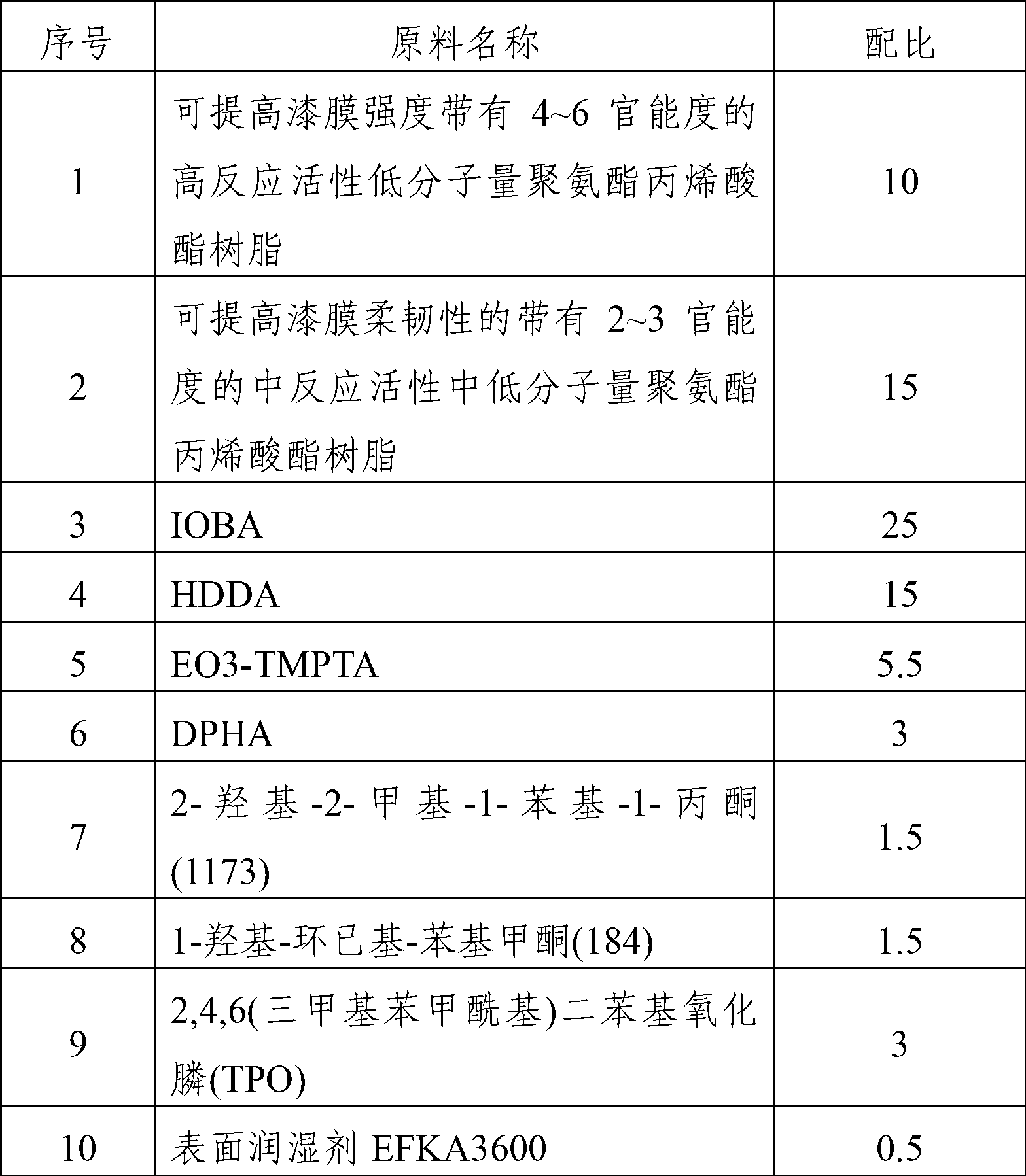

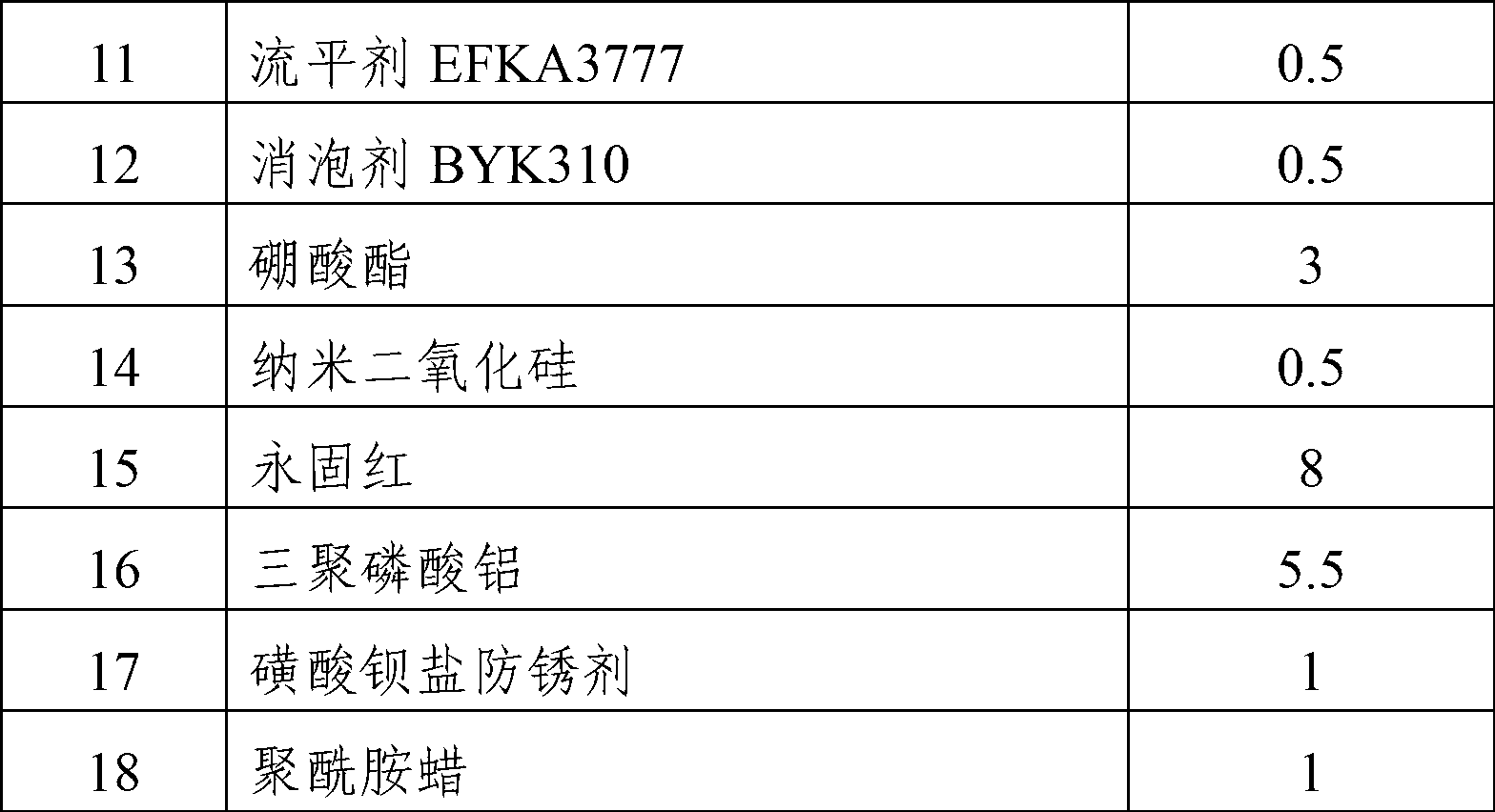

Embodiment 2

[0030] A special color UV curing coating for petroleum couplings / color rings, consisting of the following raw materials in weight percentages:

[0031]

[0032]

[0033] The specific implementation method is the same as the first embodiment.

Embodiment 3

[0035] A special color UV curing coating for petroleum couplings / color rings, consisting of the following raw materials in weight percentages:

[0036]

[0037]

[0038] The specific implementation method is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com