Online monitoring control method based on environment-friendly, energy-saving and safe cement production period

A monitoring control and production cycle technology, applied in cement production, clinker production, etc., can solve the problems of monitoring control, thermal efficiency reduction, and enterprise production cost increase, and achieve the effect of ensuring safety, stability, and thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

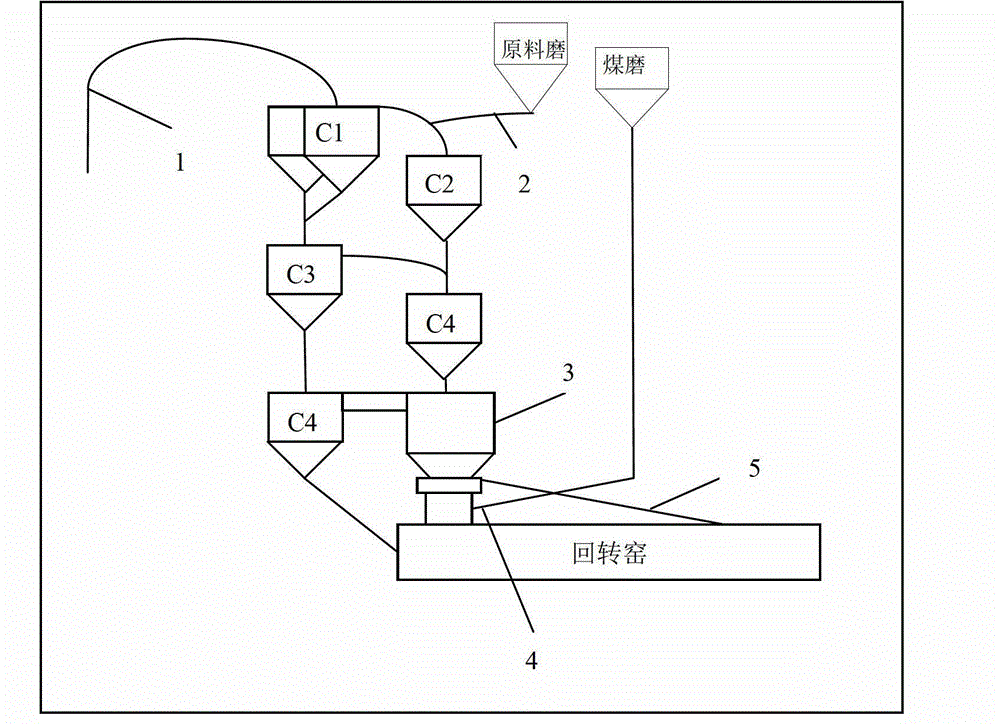

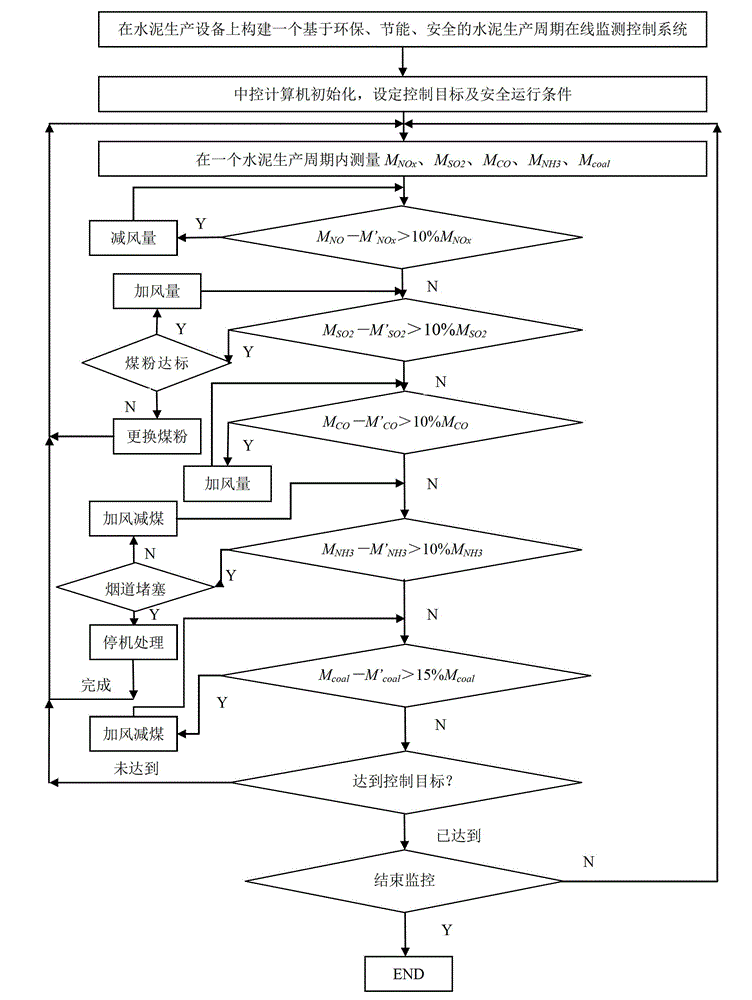

[0064] The following is based on the drawings in the description figure 1 , and the examples further illustrate the invention.

[0065] like figure 1 As shown in (1), it is installed at the exhaust pipe connected to the outlet of the preheater. The installation can monitor NOx, SO 2 , CO, NH 3 A comprehensive gas detector sensor for the emission and flow rate of air pollutants, and the sensor is connected to a computer located in the central control room. Among them, the measured value of NOx is completely converted into NO 2 count. According to the embodiment, the design scale of the production line is 5,000 tons of clinker / day, and the actual production scale is 5,800 tons / day. According to the actual situation of the cement plant, under the condition of continuous production within 3 hours, the integrated gas detection is continuously performed. The sensor measures the emission of the following gas pollutants. The emission is expressed by the concentration unit, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com