Defluorination process for drinking water

A drinking water and process technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the defluorination equipment cannot be used for a long time, the fluorine reaches the standard, and the defluorination filter material is used. Short life and other problems, to achieve the effect of long-term stable defluorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

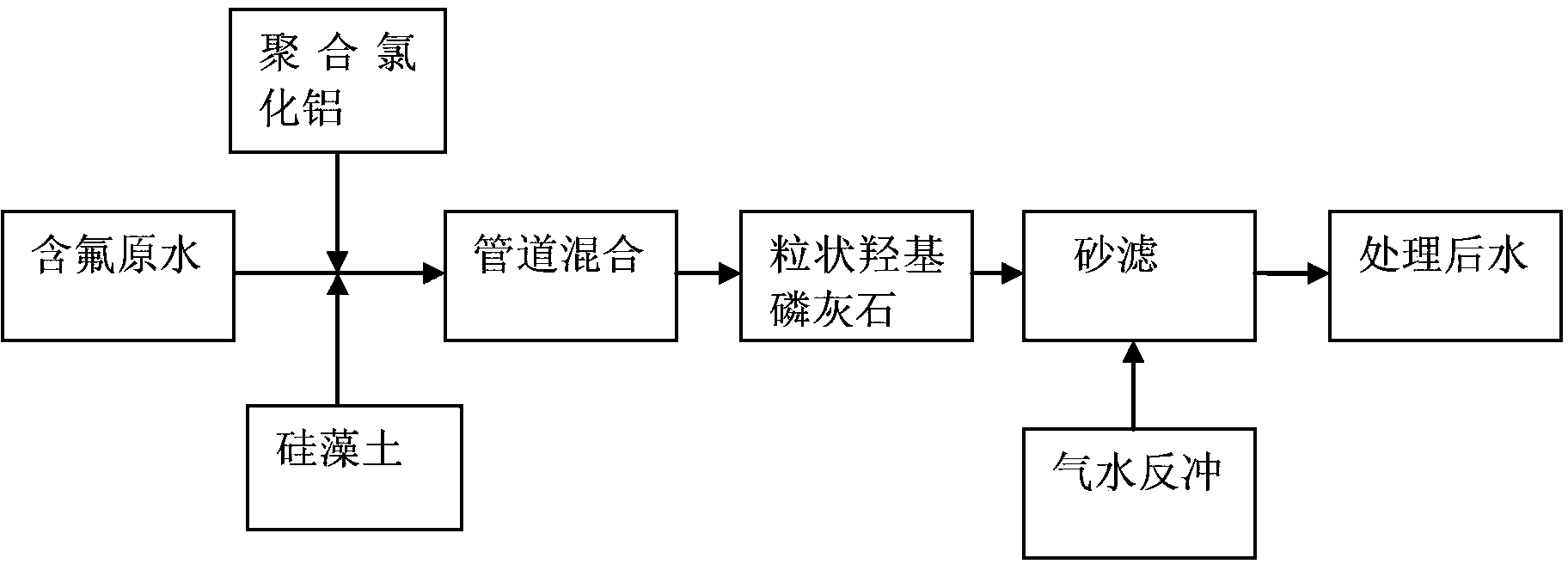

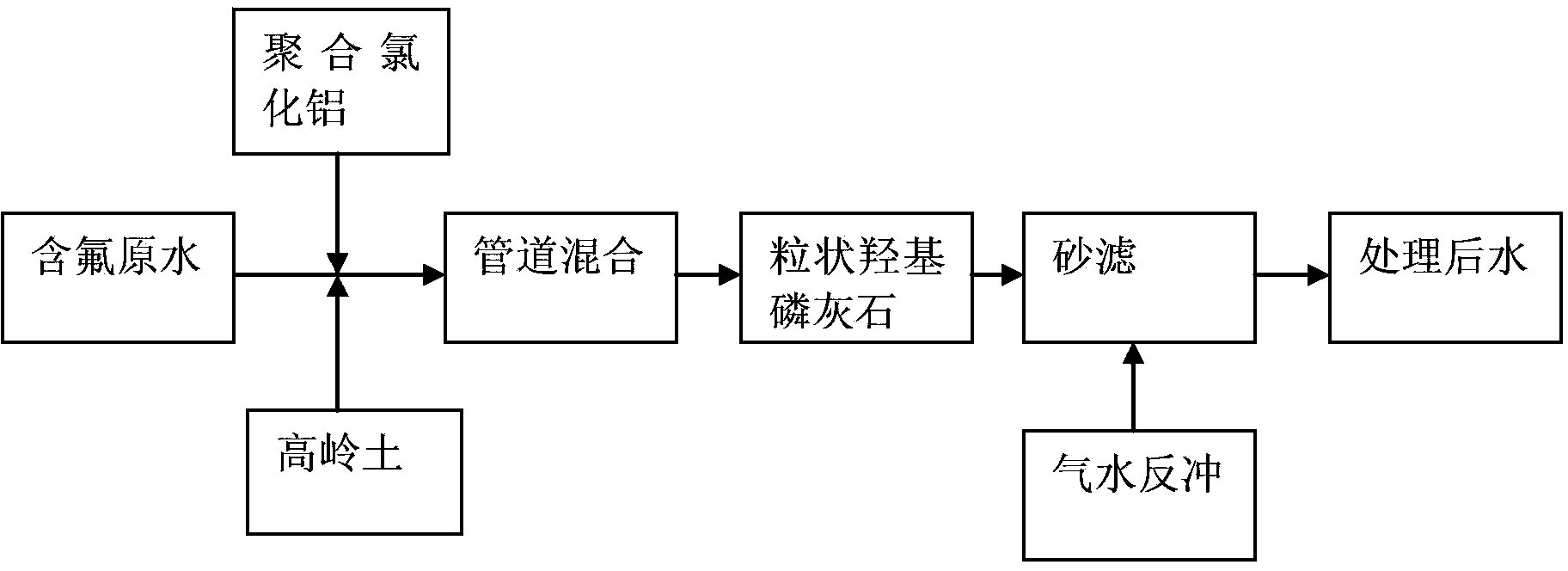

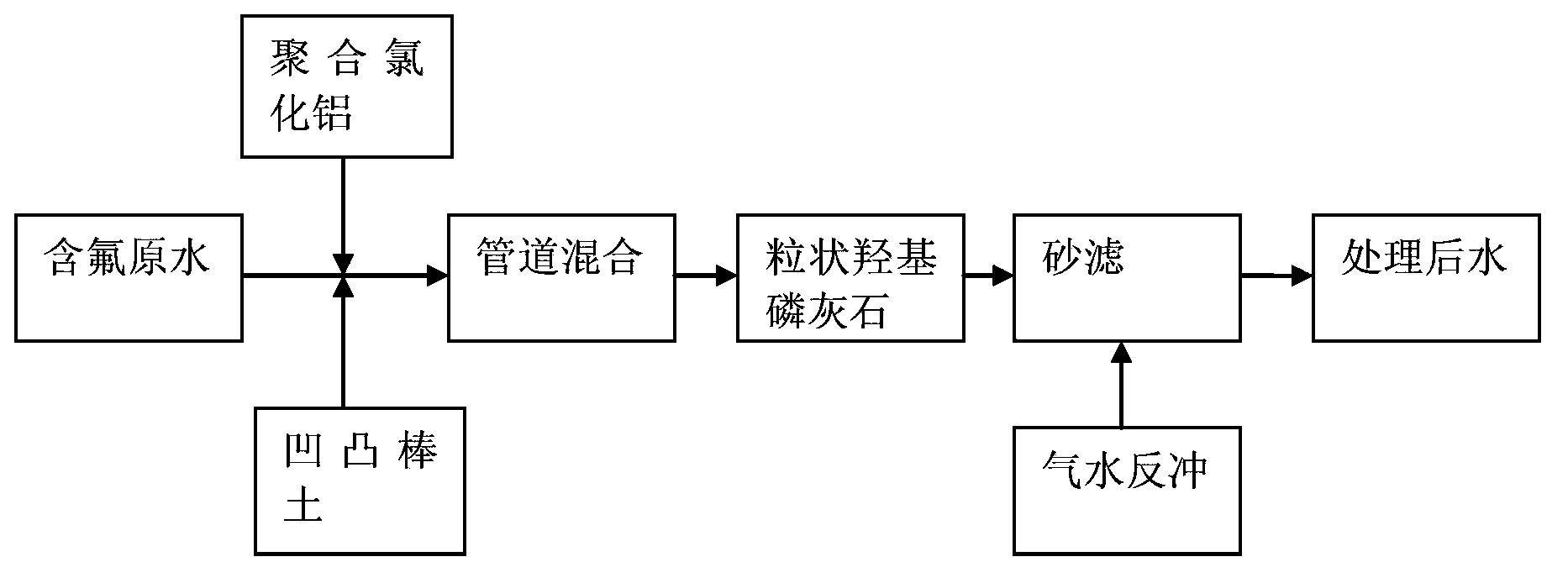

[0015] A kind of drinking water defluoridation process, the concrete steps of this process are:

[0016] (1) Add 50ppm-150ppm polyaluminum chloride to 1 ton of raw water to remove part of the fluorine in the water;

[0017] (2) Continue to add 10ppm to 50ppm of diatomite or kaolin or attapulgite to the water, and mix thoroughly after adding. The diatomite or kaolin or attapulgite will react with polyaluminum chloride to further reduce the water content. Reduce the residual amount of aluminum and reduce the content of fluorine, and the chemical composition of diatomite, kaolin and attapulgite is basically the same;

[0018] (3) Use granular hydroxyapatite filter material to filter and remove fluorine in part of the water; the granular hydroxyapatite filter material reacts with the hydrolyzed polyaluminium chloride, causing the surface of the granular hydroxyapatite filter material to fall off and expose the fresh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com