Method of solid phase preparation of nanometer zinc oxide photocatalyst by using lignin amine template method

A nano-zinc oxide and photocatalyst technology, which is applied in zinc oxide/zinc hydroxide, light water/sewage treatment, textile industry wastewater treatment, etc., to achieve good effect, excellent photocatalytic performance, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

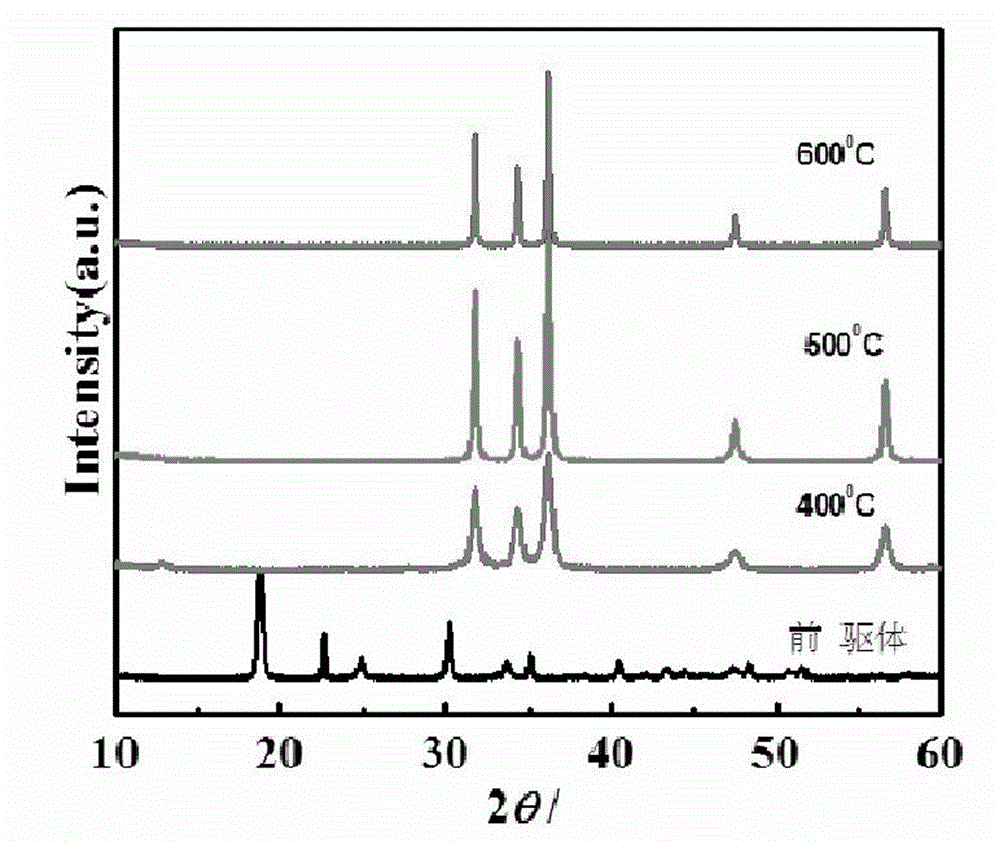

[0034] The solid-phase preparation of nano-zinc oxide photocatalyst by lignin amine template method, the specific steps are as follows:

[0035] 1. Take 5g of purified and degraded alkali lignin at room temperature and put it in a 250mL round bottom flask, add 30mL of deionized water and 0.5g of NaOH, stir for 10min, add 1.2mL of formaldehyde, stir for 10min, then add 1.50mL of tetraethylene Pentaamine, stirred for 10 minutes, heated and refluxed at 75°C for 3 hours, cooled to room temperature, filtered, added 10% potassium ferricyanide solution to the filtrate to completely precipitate the prepared ligninamine, filtered under reduced pressure, and washed several times Remove excess potassium ferricyanide, put the filter cake in a constant temperature drying oven at 60°C for 10 hours;

[0036] 2. Add 14.87g Zn(NO 3 ) 2 ·6H 2 O and 6.70 g NaC 2 o 4 Grind them in different mortars for 15 minutes, then transfer them to the same mortar, add 1.0 g of the ligninamine synthesize...

Embodiment 2

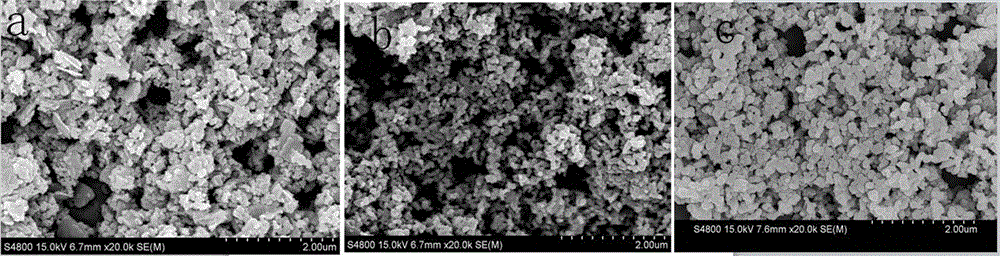

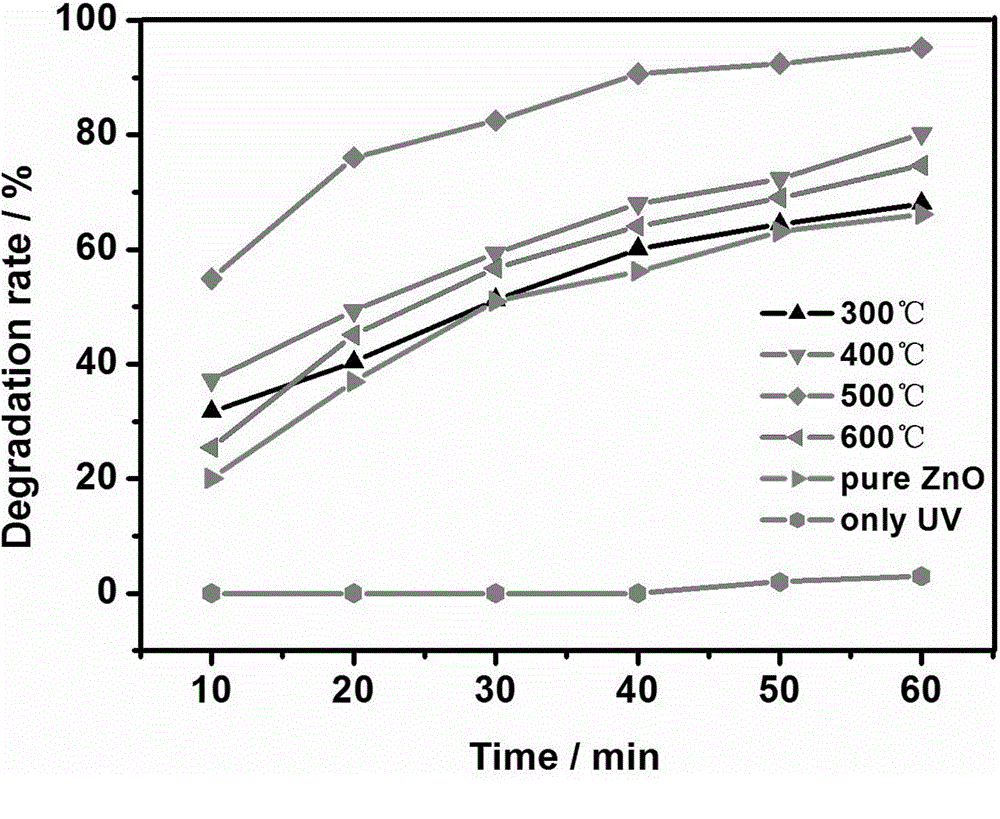

[0038] The preparation of nano-zinc oxide photocatalyst in solid phase by lignin amine template method is the same as in Example 1, except that the amine used is triethylenetetramine, and finally the sample is roasted at 400°C for 3 hours to obtain milky white nano-zinc oxide photocatalyst. Catalyst with an average particle size of 34nm. The obtained sample was subjected to a photocatalytic degradation test, using methyl orange as a model, and the degradation rate was 81% under 60 minutes of light.

Embodiment 3

[0040] Preparation of nano-zinc oxide photocatalyst in solid phase by lignin amine template method is the same as in Example 1, except that the sample is finally roasted at 500°C for 2h to obtain a white nano-zinc oxide photocatalyst with an average particle size of 18nm. In the photocatalytic degradation test, methyl orange was used as a model, and the degradation rate was 96% under 60 minutes of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com