Energy-consumption-free dedusting system

A technology of dust removal system and dust collector, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of inestimable human, material and financial resources, large limitations of dust removal equipment, increased investment and cost, etc. Conducive to safe and civilized production, reducing installation costs and maintenance costs, and reducing related investment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

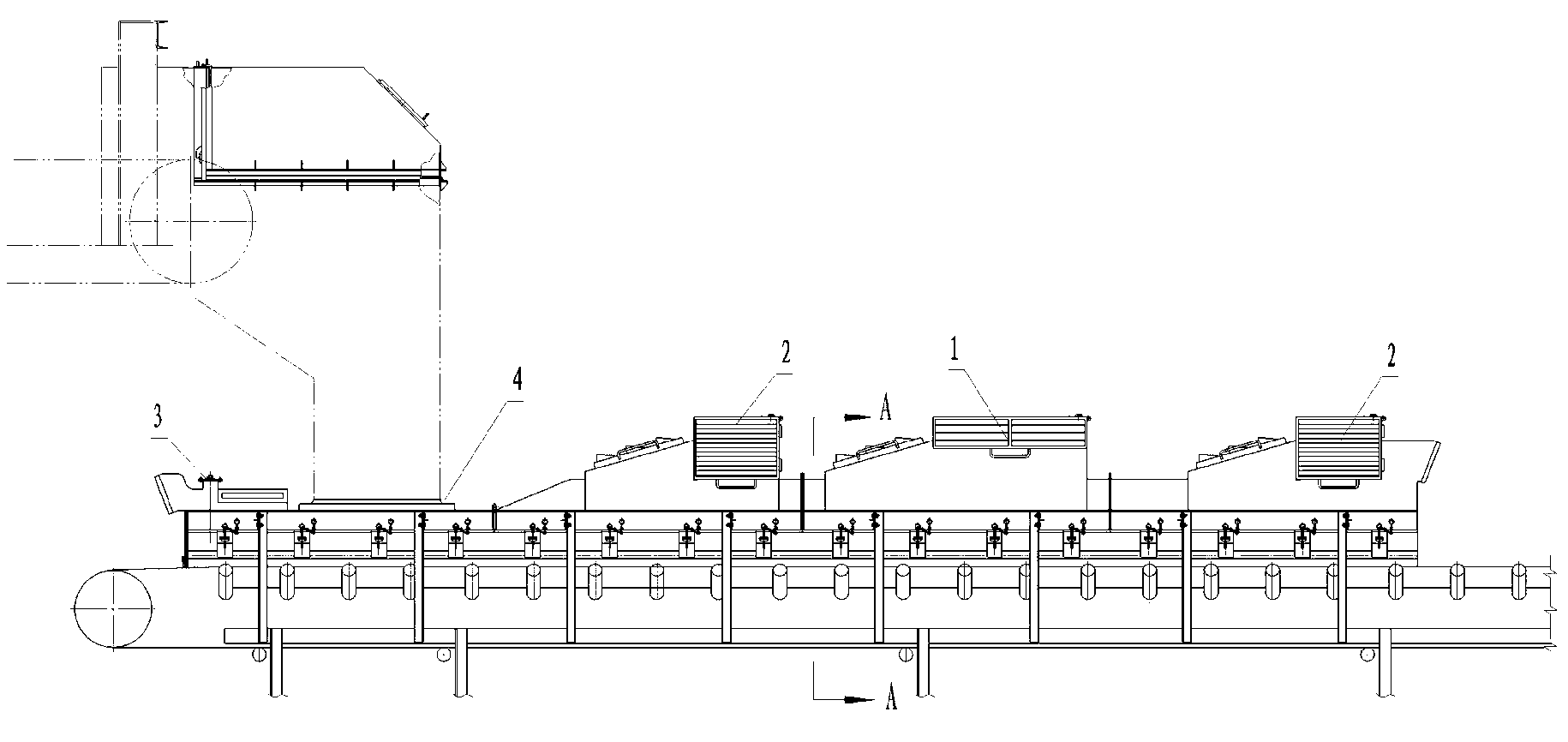

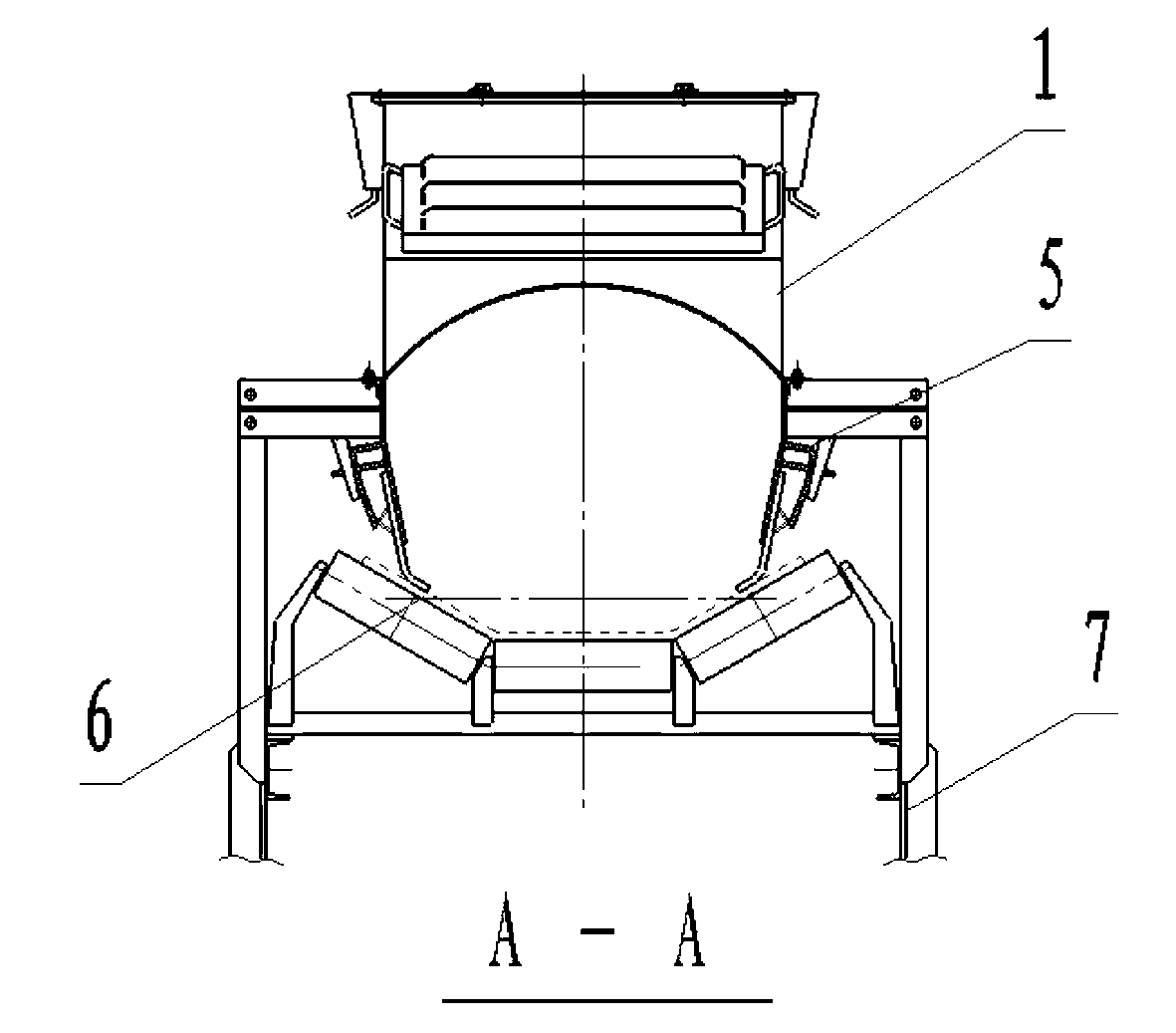

[0051] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 . The energy-free dedusting system, the present invention consists of the energy-free deduster 1, the tail pressure relief device 3 and the reduced energy-free deduster, that is, the auxiliary non-energy deduster 2, which are arranged and installed at the material receiving point of the belt conveyor 7. Composed above the guide groove 5 on the belt 6, wherein:

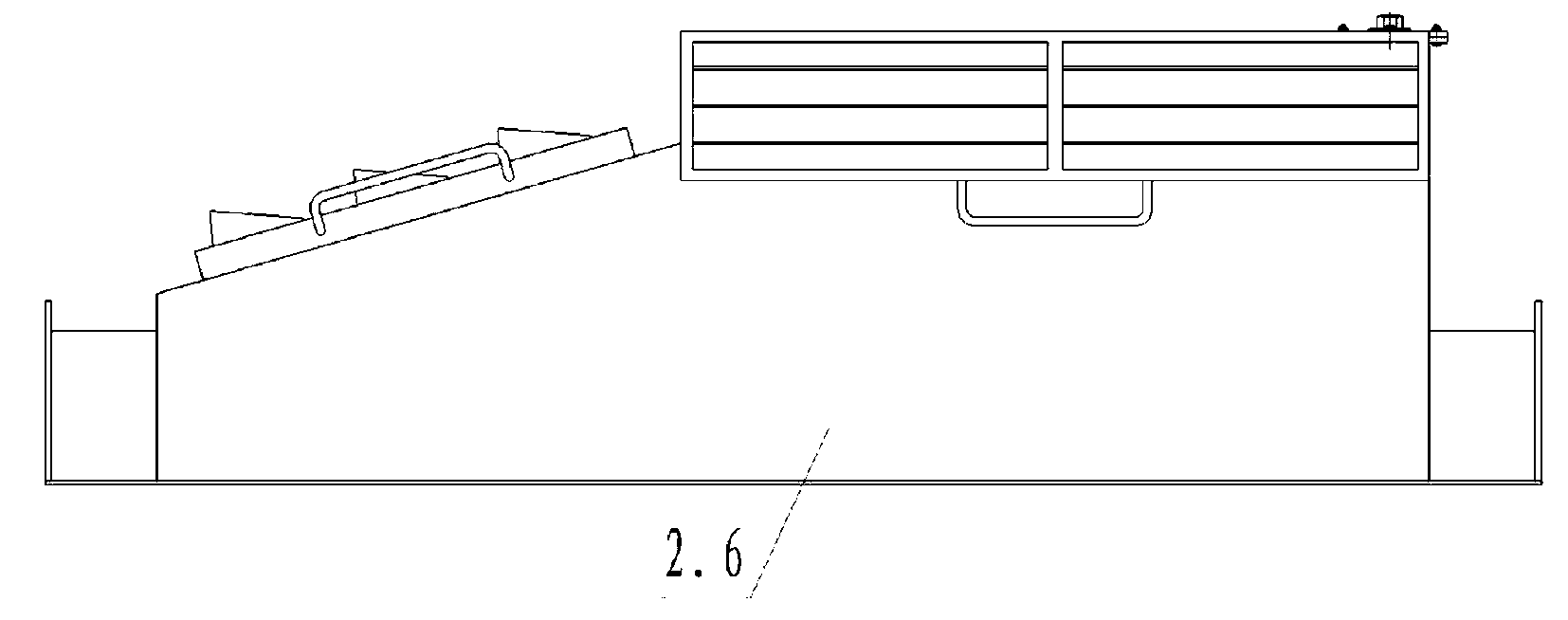

[0052] The energy-free dust collector 1 includes a bottom span 2.7 with a bottom surface of the shell 2.6, a manhole separation pressure relief device 2.1, a long fiber fleece retardation array 2.2, a diffusion condenser 2.3, and a top separation pressure relief device arranged in the shell 2.4. The air-blocking soft curtain is hung on the screw rod 2.5. Its connection structure is: the manhole separation pressure relief device 1.2 is arranged at the front end of the shell, the diffusion condenser 1.3 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com