Anti-corrosion type fiber enhanced epoxy resin composite floor material and preparation method thereof

A technology of epoxy resin coating and epoxy resin, which is applied in the direction of epoxy resin coating, anti-corrosion coating, fire-proof coating, etc., and can solve the problems of short service life of the floor, harsh construction environment, easy hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

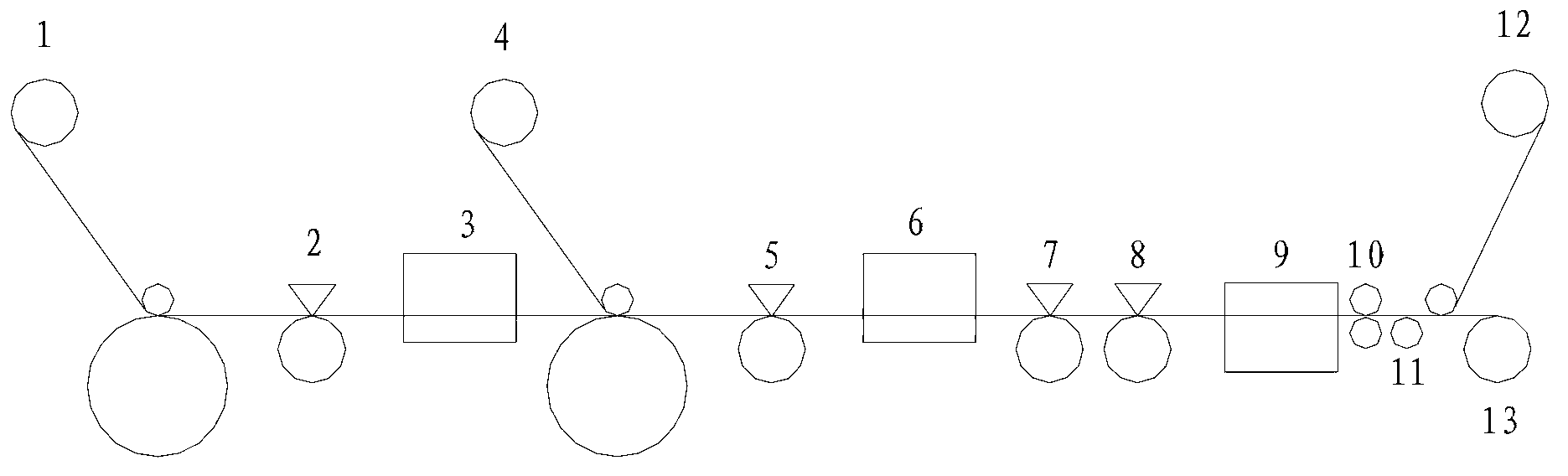

Image

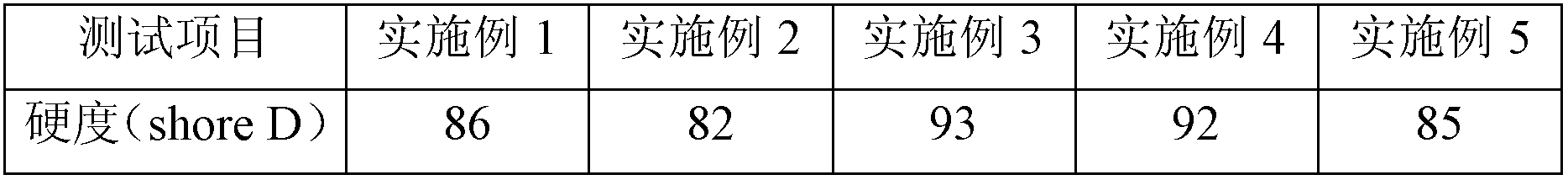

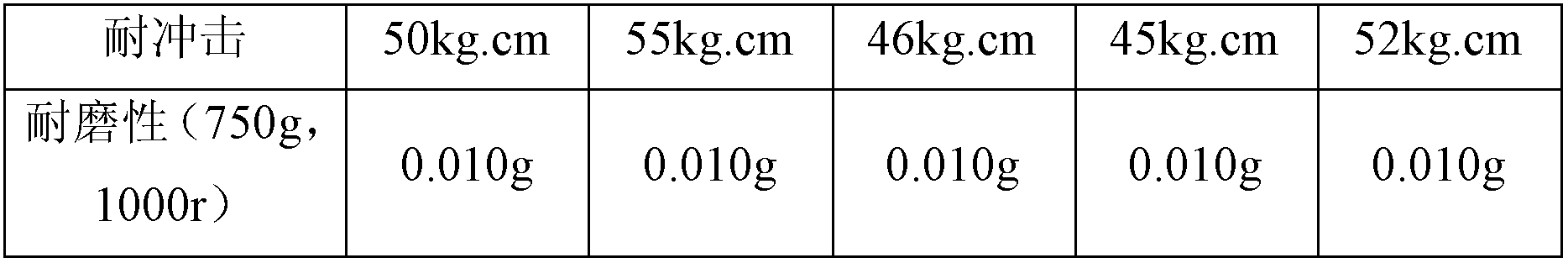

Examples

Embodiment 1

[0124] The preparation of anti-corrosion fiber-reinforced epoxy resin composite floor material comprises the following steps:

[0125] (1) Preparation of component A

[0126] (1-1) Preparation of nano-modified epoxy resin: add 5 parts of quaternary ammonium salt modified montmorillonite to 100 parts of epoxy resin (40 parts of which are E-03 resin, 60 parts are E51 resin) , high-speed stirring for 50 minutes to obtain nano-modified epoxy resin;

[0127] Among them, the preparation method of montmorillonite modified by quaternary ammonium salt: prepare sodium-based montmorillonite into a suspended aqueous solution with a mass fraction of 10%, stir and heat to 50-60°C, continue stirring for 30 minutes, add 10% mass fraction % cetyl dimethyl benzyl ammonium chloride aqueous solution, the mass ratio of the cetyl dimethyl benzyl ammonium chloride aqueous solution to sodium montmorillonite is 0.5%, heated to 50-60 ° C, Stirring was continued for 6h, and the reactant was suction fi...

Embodiment 2

[0142] The preparation of anti-corrosion fiber-reinforced epoxy resin composite floor material comprises the following steps:

[0143] (1) Preparation of component A

[0144] (1-1) Preparation of nano-modified epoxy resin: add 5 parts of quaternary ammonium salt modified montmorillonite to 100 parts of epoxy resin (40 parts of which are E-03 resin, 60 parts are E51 resin) , high-speed stirring for 50 minutes to obtain nano-modified epoxy resin;

[0145] (1-2) be 75% nano-modified epoxy resin by weight percentage, 5% resol type phenolic resin (number average molecular weight 460, solid content 75%), 5% mica (1200 order), 3% Toughener EP-2000, 3% zinc borate, 8% thinner BGE, 0.2% leveling agent BYK-307, 0.2% defoamer BYK088 and 0.6% anti-scratch agent polydimethylsilane The oxane is mixed evenly to obtain the A component.

[0146] The preparation of the B component, the C component and the D component is the same as in Example 1, and the A component and the B component are mi...

Embodiment 3

[0152] (1) Preparation of component A

[0153] (1-1) Preparation of nano-modified epoxy resin: Add 9 parts of quaternary ammonium salt modified montmorillonite to 100 parts of epoxy resin (20 parts of which are E-03 resin, 80 parts are E51 resin) , high-speed stirring for 50 minutes to obtain nano-modified epoxy resin;

[0154] (1-2) 60% nano-modified epoxy resin, 15% resol type phenolic resin (number average molecular weight 460, solid content 75%), 8% toughening agent Qishi QS-BE, 3% of zinc borate, 11.4% of diluent AGE, 0.3% of leveling agent BYK-307, 0.3% of defoamer BYK088 and 2% of anti-scratch agent polydimethylsiloxane were mixed uniformly to obtain A components.

[0155] The preparation of the B component, the C component and the D component is the same as in Example 1, and the A component and the B component are mixed in a ratio of 10:1 by weight to obtain the first epoxy resin coating; the C component and Component B was mixed in a weight ratio of 10:2 to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com