Manufacture method of break piston

A manufacturing method and technology for pistons, which are applied in the directions of pistons, transportation and packaging, railway car body parts, etc., can solve the problems of complex process, unsmooth operation of the piston rod, reduced production efficiency and work efficiency, etc., so as to simplify the processing technology, improve the The effect of production efficiency and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, the structure and principle of the present invention will be described in detail with reference to the accompanying drawings.

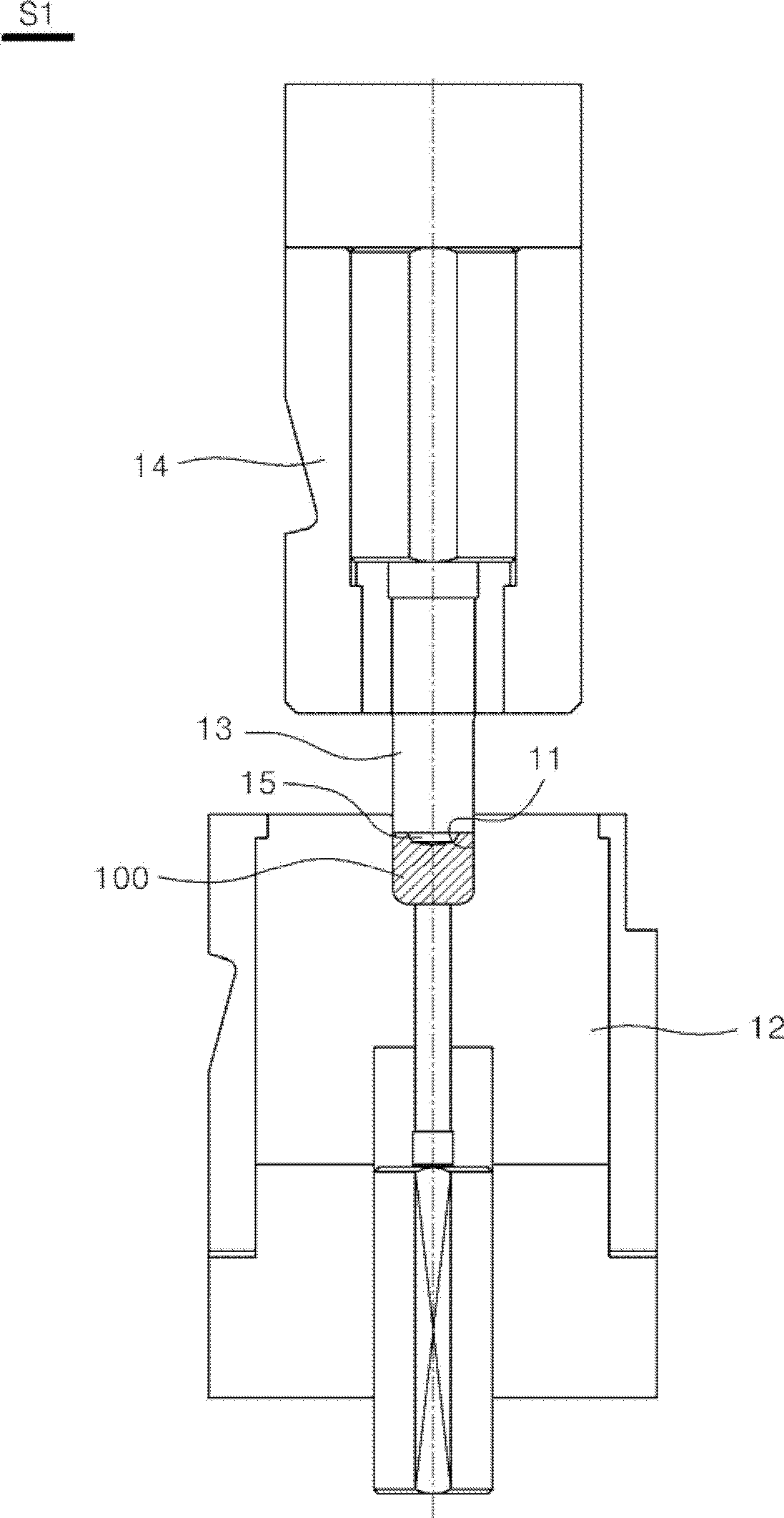

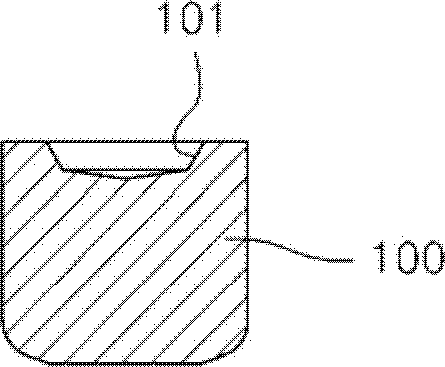

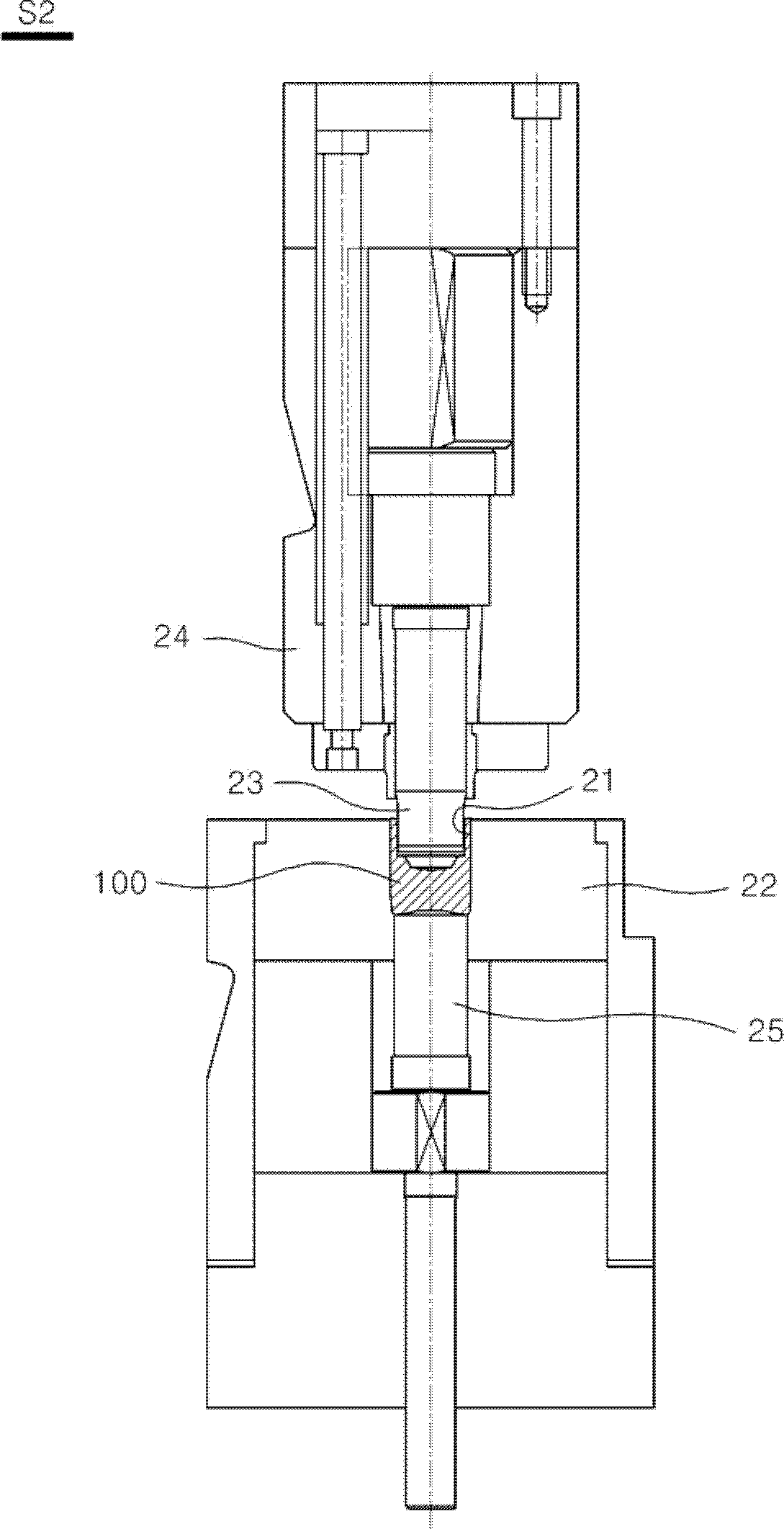

[0054] As shown in the figure, the manufacturing method of the brake piston of the present invention includes: the first process S1 of machining the positioning groove 101 on the casting 100 constituting the piston; the second process S2 of machining the first hollow part 102 on the casting 100; bevel machining on casting 100 The third process S3 of forming the channel groove processing surface 103 ; the fourth process S4 of processing the third hollow portion 104 on the casting 100 ; and the fifth process S5 of processing the second hollow portion 105 on the casting 100 .

[0055] The first process S1 is as figure 1 and figure 2 As shown, the casting 100 is introduced into the first casting introduction part 11 of the first molding die 12 with the first casting introduction part 11 formed on the inner surface of the upper end....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com