Fermenting bed bioactive padding and preparation and application methods thereof

A bioactive, fermentation bed technology, applied in biochemical equipment and methods, microorganism-based methods, applications, etc., can solve problems such as imperfection and lack of bedding formula, and achieve pollution improvement, elimination of non-point source pollution, and good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

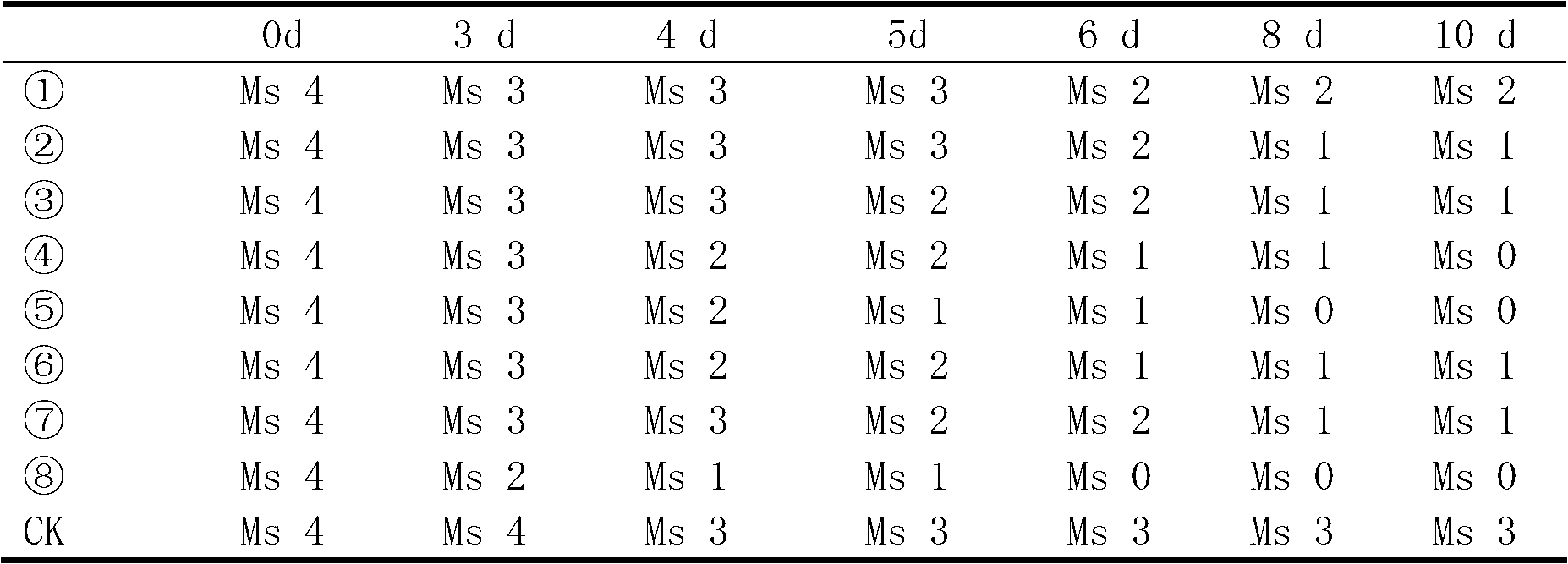

Image

Examples

Embodiment 1

[0061] Embodiment 1: the preparation of fermentation agent

[0062] 1) Preparation of fermentation product of Bacillus subtilis CGMCC1.1413

[0063] First, the Bacillus subtilis is activated on a slant, and the shake flask seeds are cultivated;

[0064] Then carry out fermenter culture: the medium loading in the fermenter is 40% to 50% of the total volume, the inoculation amount accounts for 0.1% to 0.3% of the medium volume, the fermentation temperature is 35°C to 37°C, and the air is stirred at 200rpm to 220rpm For cultivation, the ratio of aeration volume to fermentation broth volume is 1:1~1.1:1, tank pressure is 0.03MPa~0.05MPa; the end point of fermentation is that the number of spores is not less than 90% of the total number of bacteria, and the number of viable bacteria in the fermentation broth is 2.0 ×10 10 cfu / mL~2.2×10 10 Between cfu / mL; the mass percentage of each component of the fermenter medium is: glucose 0.4% to 0.6%, starch 0.3% to 0.5%, bean cake powder ...

Embodiment 2

[0074] The preparation of embodiment 2 fermented bedding material

[0075] (1) Expose sawdust, rice husk and straw to the sun for 1-2 days;

[0076] (2) Cut the straw into 1-2cm;

[0077] (3) Weigh each raw material according to the following weight:

[0078] 32kg of sawdust, 43kg of rice husk, 22kg of straw, 2.8kg of brown sugar, 0.2kg of compound microbial fermentation agent (the fermentation product prepared in Example 1 is mixed with protease, wherein the effective live bacteria content is 8.0×10 9 cfu / g, protease activity is 35U / g. The bacterial count percentage of Bacillus subtilis is 60%, and the bacterial count percentage of Lactobacillus casei is 40%. )

[0079] (4) Fully mix the brown sugar with the fermenting agent and dilute the fermenting agent;

[0080] (5) Mix the sawdust, rice husk and straw evenly in the fermentation tank, then mix the dilution of the fermentation agent with the above litter mixture evenly, and control the moisture content at about 50%;

...

Embodiment 3

[0082] The preparation of embodiment 3 fermented bedding material

[0083] (1) Expose sawdust, rice husks, and cotton stalks to the sun for 1-2 days;

[0084] (2) Crush the cotton stalk;

[0085] (3) Weigh each raw material according to the following weight:

[0086] Sawdust 36kg, rice husk 40kg, cotton stalk 21kg, brown sugar 2.7kg, compound microbial fermentation inoculant 0.3kg (the fermented product prepared in embodiment 1 mixes with protease, and wherein effective live bacteria content is 7.7 * 10 9 cfu / g, protease activity is 37U / g. The bacterial count percentage of Bacillus subtilis is 50%, and the bacterial count percentage of Lactobacillus casei is 50%. )

[0087] (4) Fully mix the brown sugar with the fermenting agent and dilute the fermenting agent;

[0088] (5) Mix the sawdust, rice husk and cotton stalk powder evenly in the fermentation tank, and then mix the diluted fermentation agent with the above litter mixture evenly again, and the moisture content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com