Spherical hollow porous MnO/C composite material and application thereof

A composite material, hollow technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor reaction kinetics, poor rate performance, material agglomeration, etc., to achieve excellent cycle stability, excellent rate performance, enhanced Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

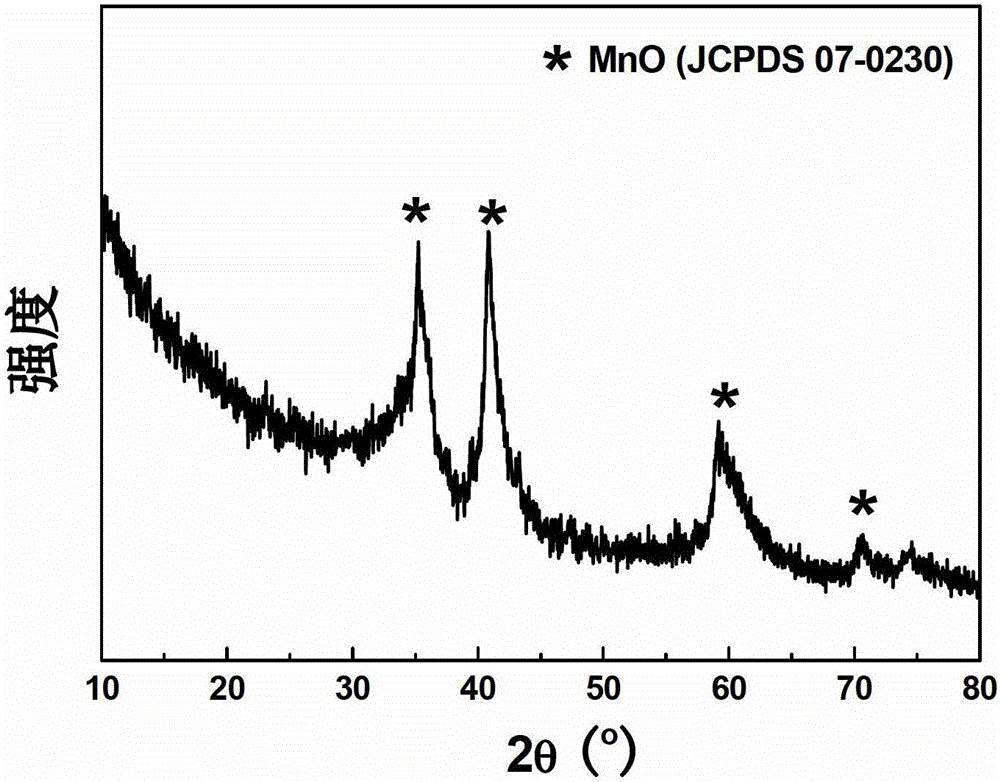

[0033] Firstly, 1.58g of potassium permanganate and 1.42g of sodium sulfate were evenly dispersed in 50mL of deionized water, and then 50mL of pretreated Nannochloropsis concentrate was added. After soaking for 1 hour, Nannochloropsis was separated from the solution, washed several times with deionized water, and placed at a temperature of 80 o It is dried in the oven of C to obtain the precursor product. Take 0.5g of the dried precursor powder and place it in a crucible, add 5mL of N,N-dimethylformamide solution containing 0.05g / mL polystyrene, and then place the crucible at a temperature of 500 o In the high-temperature fixed-bed reaction furnace of C, nitrogen with a flow rate of 200 sccm was introduced as a protective gas, and the final product was obtained after 2 hours of reaction, which was a spherical hollow porous MnO / C composite material. figure 1 It is the XRD diffraction pattern of the material, and it can be seen from the standard card that the obtained product i...

Embodiment 2

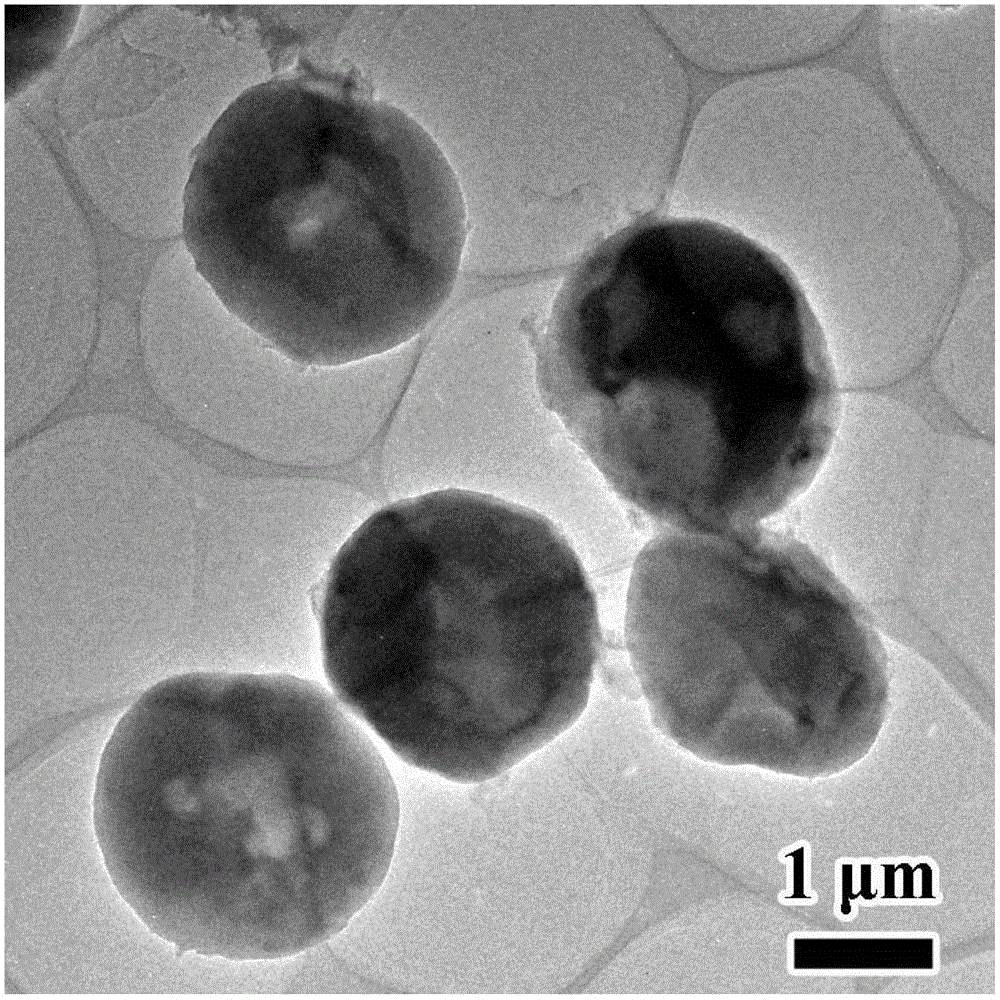

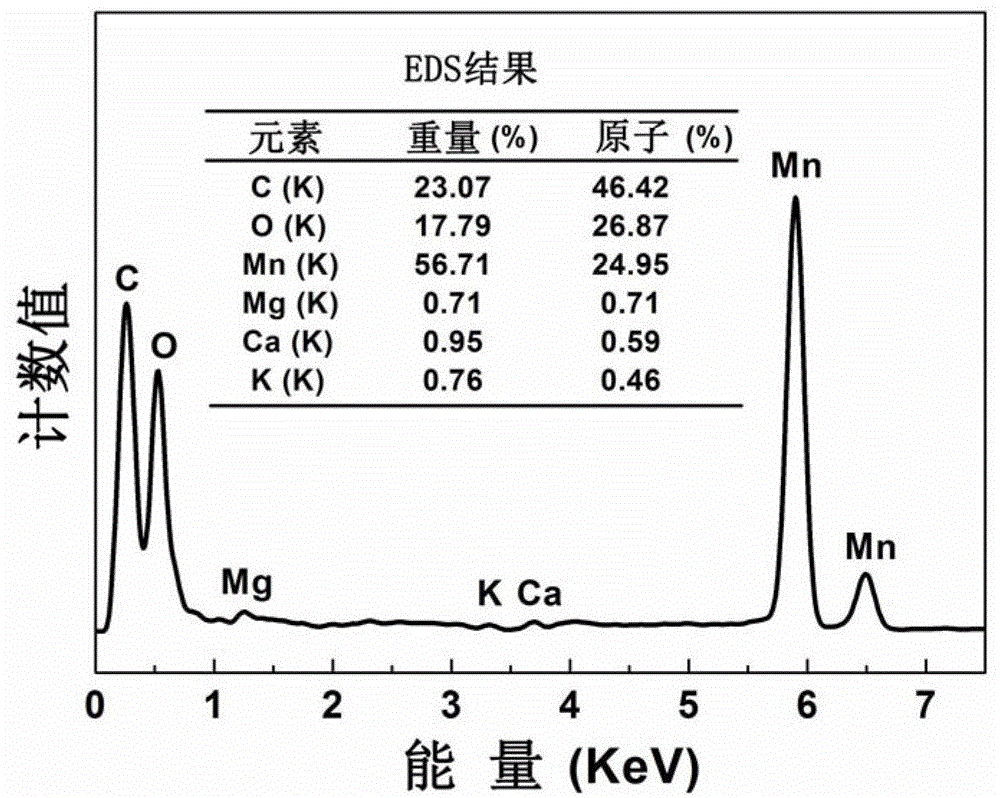

[0037] Firstly, 4.74g of potassium permanganate and 4.26g of sodium sulfate were evenly dispersed in 80mL of deionized water, and then 20mL of pretreated chlorella concentrate was added. After soaking for 1 hour, the chlorella was separated from the solution, washed several times with deionized water, and placed at a temperature of 80 o The oven of C dries it to obtain the precursor product. Take 1g of the dried precursor powder and place it in a crucible, add 6mL of 0.06g / mL glucose aqueous solution, and then place the crucible at a temperature of 600 o In the high-temperature fixed-bed reaction furnace of C, argon gas with a flow rate of 500 sccm was introduced as a protective gas, and the final product was obtained after 4 hours of reaction, which was a spherical hollow porous MnO / C composite material. The XRD pattern of the composite product is similar to figure 1 , looks like figure 2 , composed like image 3 .

[0038] The prepared spherical hollow porous MnO / C com...

Embodiment 3

[0040] Firstly, 7.9g of potassium permanganate and 7.1g of sodium sulfate were uniformly dispersed in 60mL of deionized water, and then 40mL of pretreated Schizochytrium concentrated solution was added. After soaking for 0.5 hours, the Schizochytrium was separated from the solution, washed several times with deionized water, and placed at a temperature of 80 o The oven of C dries it to obtain the precursor product. Take 2g of the dried precursor powder and place it in a crucible, add 8mL of 0.1g / mL citric acid aqueous solution, and then place the crucible at a temperature of 650 o In the high-temperature fixed-bed reaction furnace of C, nitrogen with a flow rate of 300 sccm was introduced as a protective gas, and the final product was obtained after 6 hours of reaction, which was a spherical hollow porous MnO / C composite material. The XRD pattern of the composite product is similar to figure 1 , looks like figure 2 , composed like image 3 .

[0041] The prepared spheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com