Photoetching method and system using metal glass as photoresist

A metal glass and photolithography system technology, applied in the field of micro-nano device manufacturing, can solve the problems of high price, limitation, and the edge of the groove is not steep enough, and achieve the effect of high output rate, high cost performance, and loose operating environment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

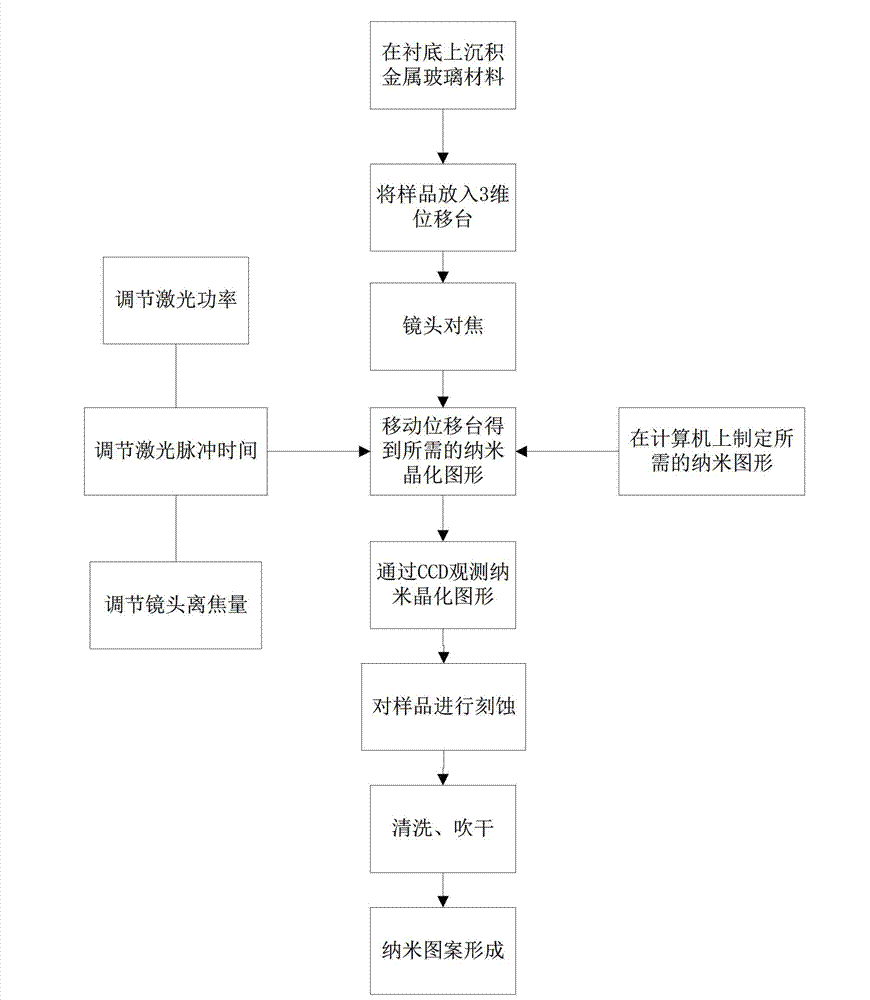

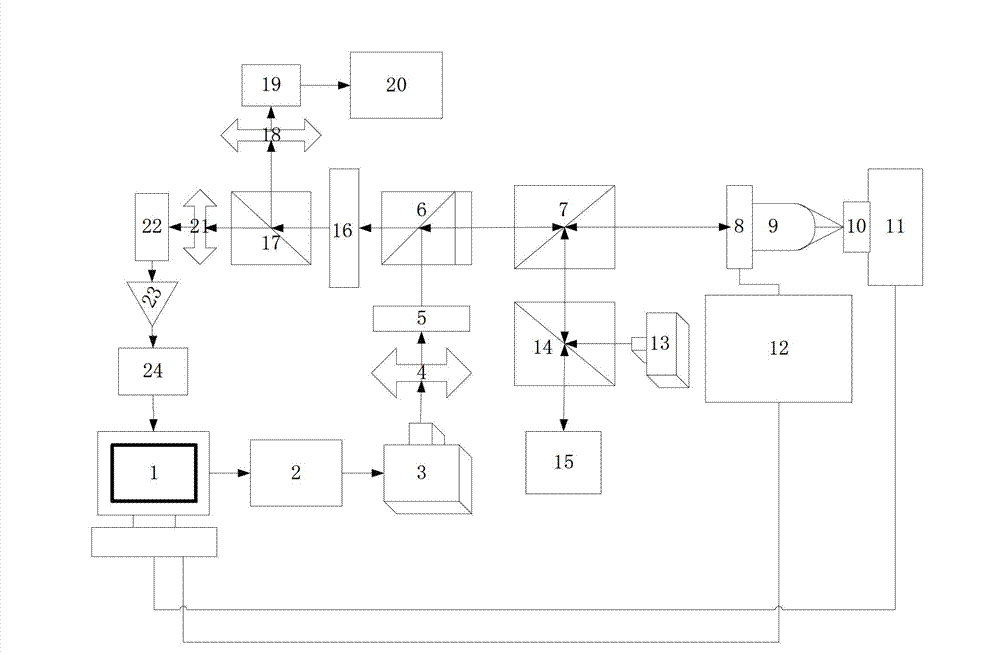

Method used

Image

Examples

Embodiment 1

[0058] MgCuY metallic glass material was prepared on a quartz substrate by magnetron sputtering method, the sputtering parameters were: power 60W, Ar pressure 0.5Pa, sputtering time 20min, target base distance 100mm;

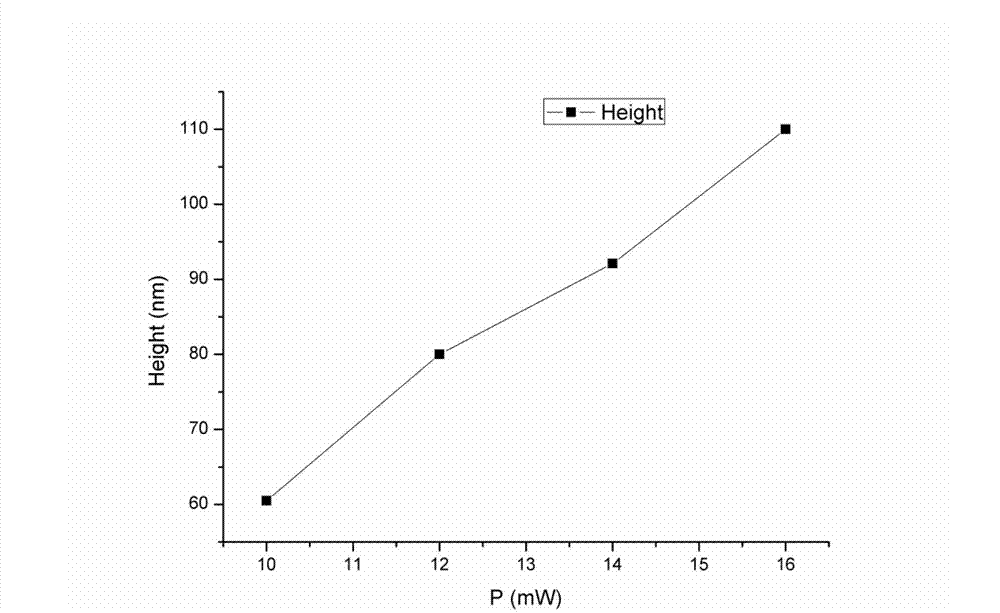

[0059] Photolithography of MgCuY metallic glass material, using Corrent-660-100-C semiconductor laser, Japan Sigma focusing lens (NA=0.4), the minimum crystallization point diameter obtained after photolithography is 600nm, which is much smaller than the spot diffraction of this lens The limit is 2.013um; expose the sample, the exposure power is 10mW, 12mW, 14mW, 16mW, and the moving rate of the three-dimensional translation stage is 100um / s; put the exposed sample into 3%HNO 3 solution for 60s, the obtained step height is as follows image 3 Shown:

[0060] It can be seen from the figure that as the laser power increases, the crystallization degree of the MgCuY metallic glass sample increases, and the step height after etching increases with the increase of la...

Embodiment 2

[0062] Exposure steps:

[0063] Using Corrent-660-100-C semiconductor laser, Japan Sigma focusing lens (NA=0.4), using magnetron sputtering method to prepare ZnS-SiO on the substrate 2 , AlNiGd, ZnS-SiO 2 The 3-layer thin film can control the lithographic crystallization line width by controlling the laser pulse time, power, and lens defocus degree;

[0064] Figure 4 is the relationship between the laser pulse time and the lithographic linewidth of the multilayer metallic glass sample; it can be seen from the figure that under the same laser power condition, the crystallization linewidth of the above three-layer film sample increases with the increase of the laser pulse time, When the pulse time is 180ns, the crystallization linewidth is 1.41um; when the pulse time is 80ns, the crystallization linewidth is 0.52um; the crystallization linewidth can be changed in a small size range by simply changing the laser pulse time; and It can be seen that at 80ns, the lithographic lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com