Device for detecting layered condition of raw coal mixture

A technology for mixtures and raw coals, which is applied in measuring devices, using electrical devices, and using piezoelectric devices to measure the force of nature, etc. problems, to achieve the effect of ensuring the quality of sorting, ensuring the efficiency of equipment operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

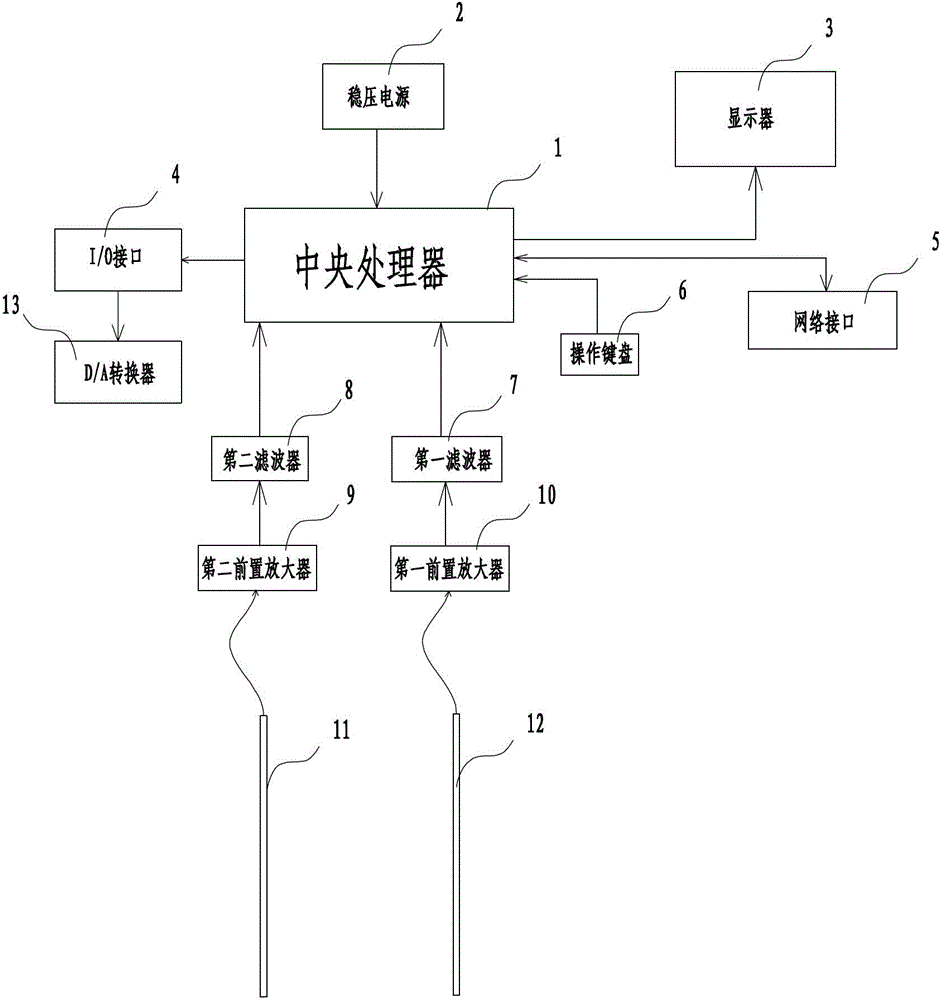

[0015] combined with figure 1 , a device for detecting the stratification of raw coal mixture, which includes a central processing unit 1, a stabilized power supply 2, a display 3, at least two detection units and an I / O interface 4 for outputting control signals to a raw coal conveying mechanism ; Stabilized power supply 2, display 3, I / O interface 4 and at least two detection units are all connected to the central processing unit 1, and the detection unit includes a filter, a preamplifier and is used to automatically detect the amount of vibration in the coal seam The electronic sensing rod, the filter, the preamplifier and the electronic sensing rod are connected in sequence, and the filter is connected to the central processing unit 1. During specific implementation, it includes two detection units, and the two detection units are a first detection unit and a second detection unit, and the first detection unit includes a first filter 7, a first preamplifier 10 and a first ...

specific Embodiment 2

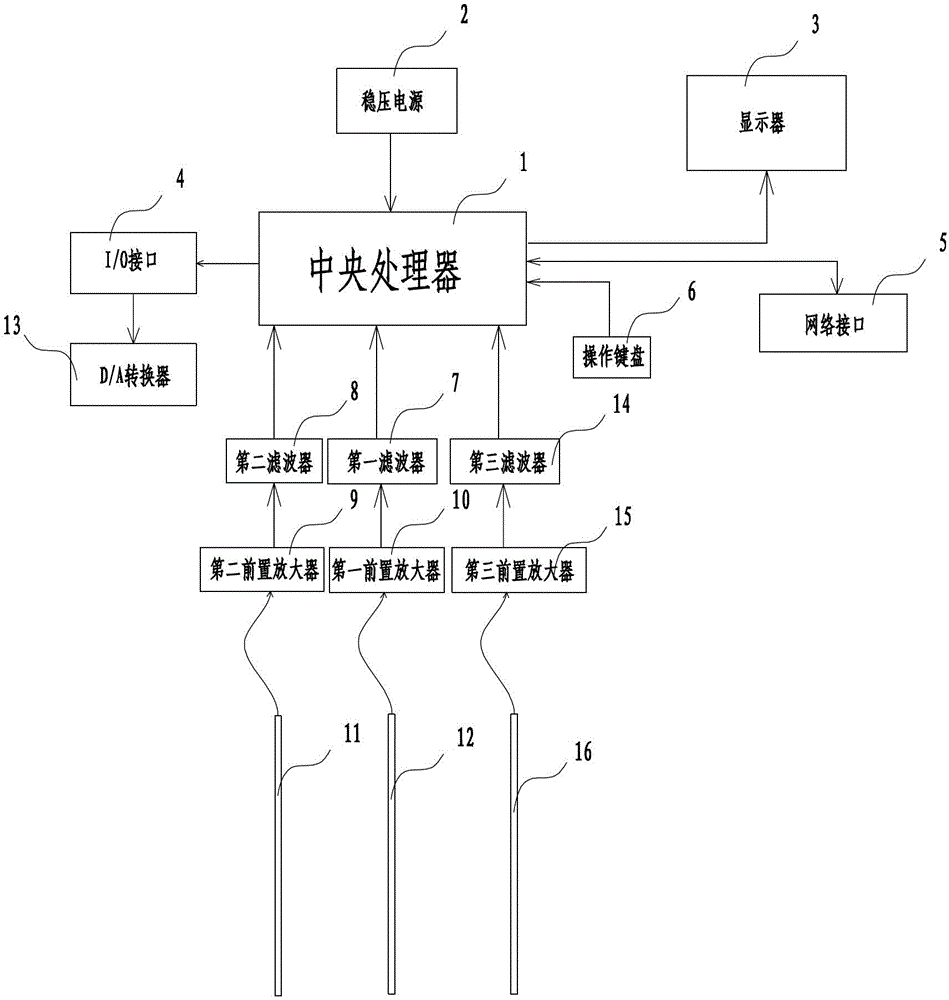

[0016] combined with figure 2 , a device for detecting the stratification of raw coal mixture, which includes a central processing unit 1, a stabilized power supply 2, a display 3, at least two detection units and an I / O interface 4 for outputting control signals to a raw coal conveying mechanism ; Stabilized power supply 2, display 3, I / O interface 4 and at least two detection units are all connected to the central processing unit 1, and the detection unit includes a filter, a preamplifier and is used to automatically detect the amount of vibration in the coal seam The electronic sensing rod, the filter, the preamplifier and the electronic sensing rod are connected in sequence, and the filter is connected to the central processing unit 1. During specific implementation, it includes three detection units, the three detection units are the first detection unit, the second detection unit and the third detection unit, and the first detection unit includes the first filter 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com