Backflow-type multistage sorting pulping machine

A pulper and fractionation technology, which is applied in the field of reflux type multi-stage sorting pulpers, can solve the problems of inability to classify and screen sand and gravel, increase sorting costs, and insufficient screening accuracy, so as to facilitate sorting, storage, and upgrading. The effect of distinguishing degree and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

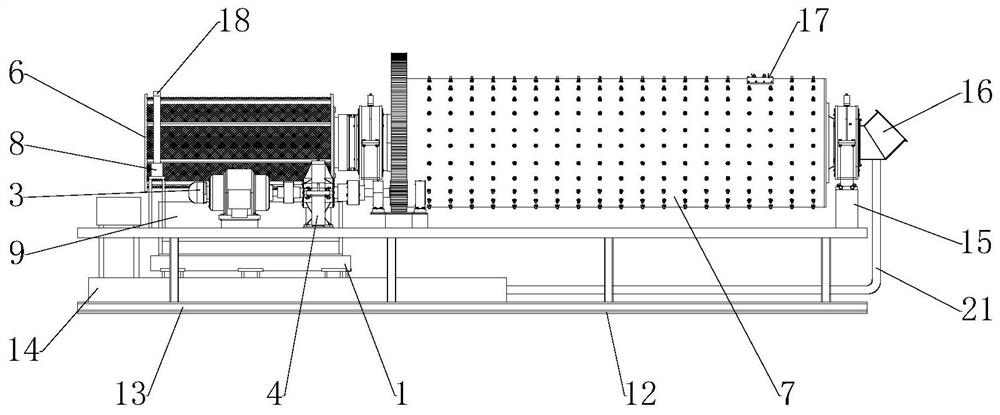

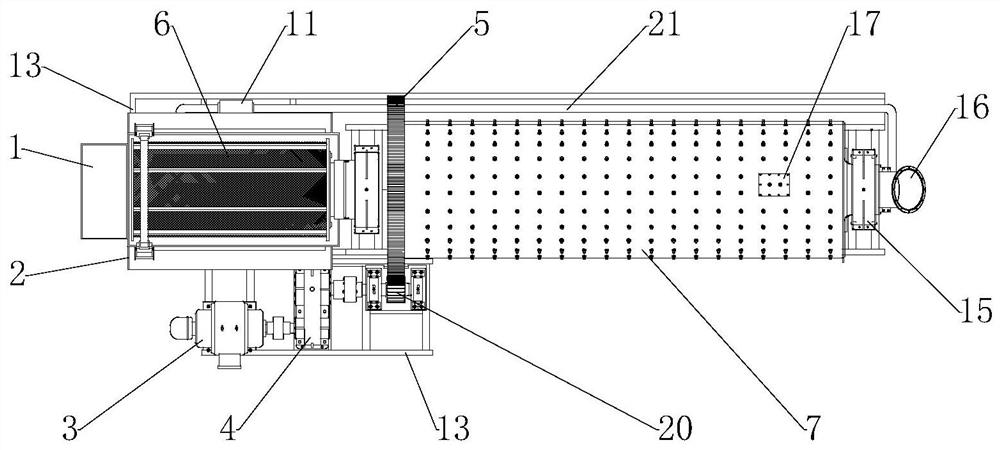

[0031] see Figure 1-Figure 6 As shown, the present invention provides a reflux type multi-stage sorting pulp machine, including a support base frame 13, the support base frame 13 is composed of a plurality of welded and fixed structural steels, and is used to provide support for the remaining parts, support The bottom frame 13 adopts a double-layer structure design, the upper layer is used to support the mixing cylinder 7, the sub-sieve cylinder 6 and the transmission equipment, and the lower layer is used to place components such as the sub-hopper 9, the liquid collection tank 14 and the collection box 1, and supports the bottom frame Above 13, a horizontally arranged mixing cylinder 7 is rotated and installed. The mixing cylinder 7 is a horizontally arranged cylindrical hollow cylinder for mixing water and materials to be sorted. The inner wall of the mixing cylinder 7 is fixed by bolts. A protective liner is installed to prevent the sand and gravel in the internal material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com