Multi-stage tobacco leaf sorting equipment

A tobacco leaf and sorting technology, applied to tobacco, prepared tobacco, conveyor objects, etc., can solve problems such as slow response speed, inability to adapt to high-speed sorting, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

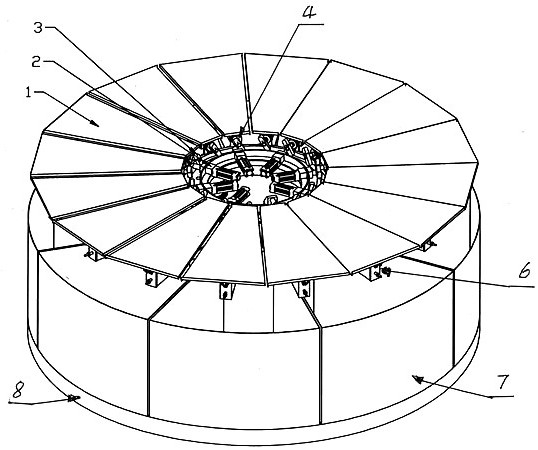

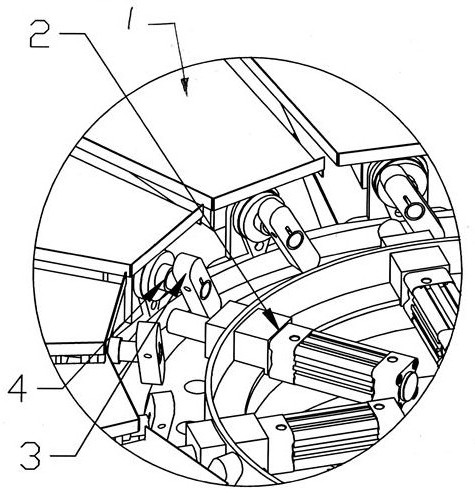

[0007] Describe embodiment in detail in conjunction with accompanying drawing, it comprises a fixed chassis 8, and above the fixed chassis, a support ring 9 is installed upwards in the center, and a rotary motor 5 is installed below the top plate of the support ring, facing the peripheral level on the top of the support ring There are a plurality of overturning rods 6 evenly distributed above the fixed chassis, and a circular fan-shaped overturning plate 1 is installed on each of the overturning rods, and a turning shaft 4 is installed on the inner end of each overturning rod. , a push rod cylinder 2 corresponding to its flip shaft is installed on the support ring corresponding to each flip shaft end, and a clamping block 3 is installed on the flip shaft head end corresponding to each push rod cylinder head, and on the fixed plate Collection boxes 7 are evenly distributed along the periphery of the support ring.

[0008] When working, driven by the rotating motor, the turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com