Double differential pressure moisture flow measuring device based on long-throat-neck venturi

A measuring device, Venturi technology, applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detected by measuring pressure difference, etc., can solve the problem of low signal-to-noise ratio of measurement signal, low signal-to-noise ratio of pressure measurement signal, and affecting the system Discrimination ability and other problems, to achieve the effect of low signal-to-noise ratio of the measurement signal, optimize the expansion angle, and lengthen the length of the throat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the accompanying drawings.

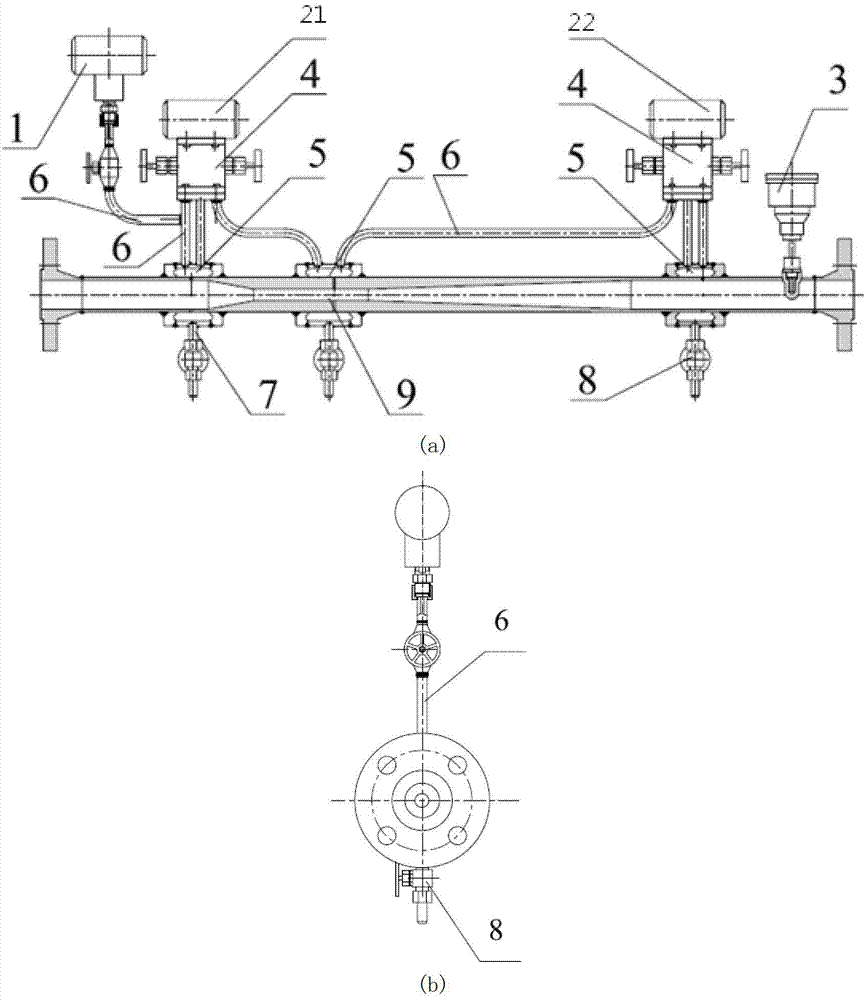

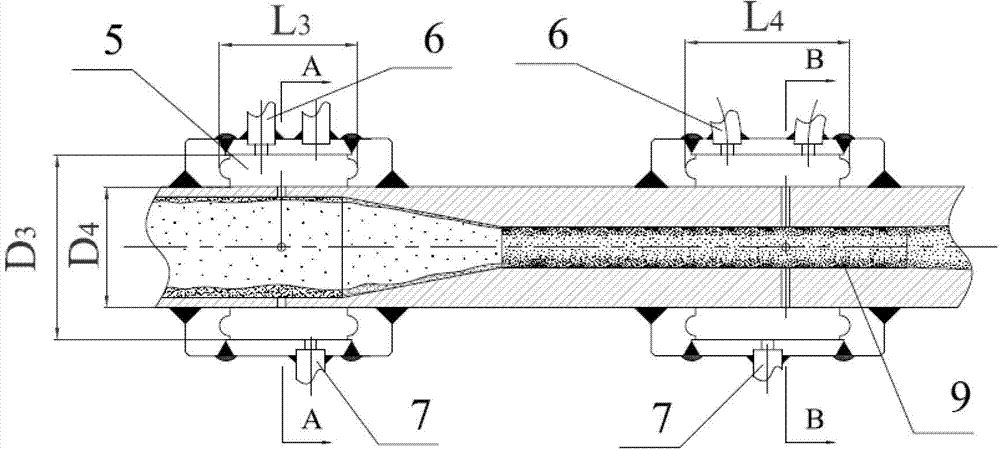

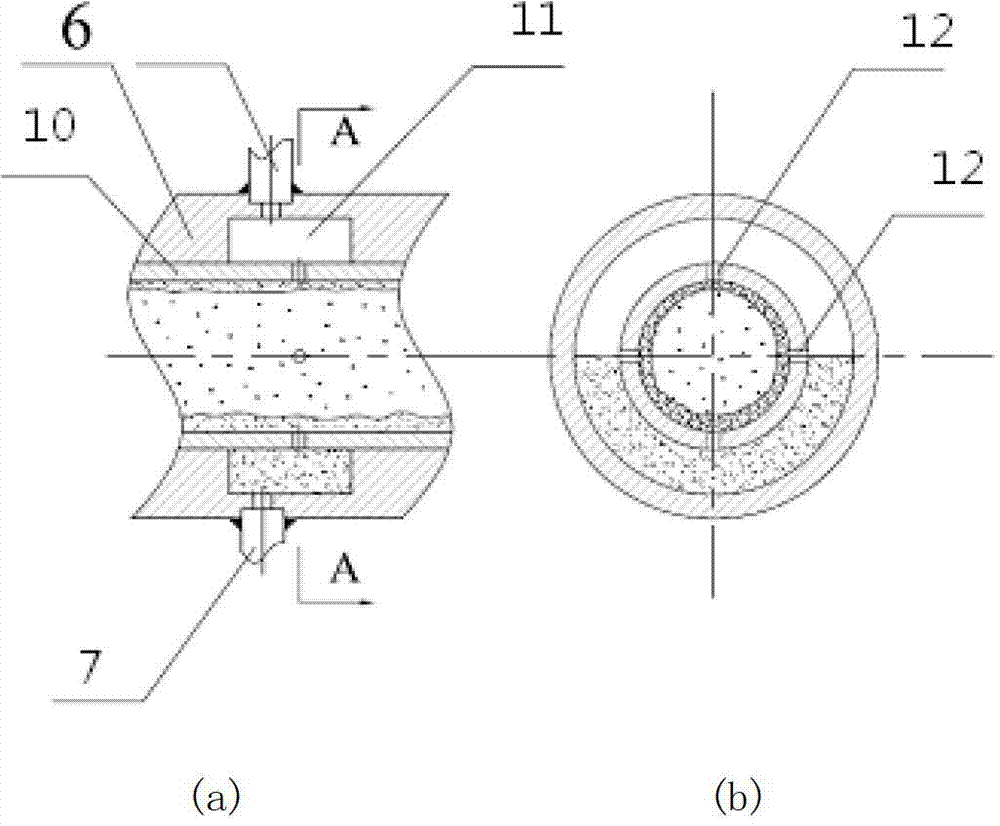

[0014] The invention is a double differential pressure wet gas flow measuring device based on a long throat Venturi. The present invention is different from the previous wet gas flow measuring device in that it adopts an annular chamber gas-liquid isolation pressure taker as the pressure takeover mechanism on the basis of the optimally designed Venturi structure.

[0015] The two transmitters share an annular gas-liquid isolation pressure taker at the throat. A pressure transmitter is installed at the upstream inlet, and the pressure introduction pipe of the transmitter can be bypassed by the upstream pressure introduction pipe of the first differential pressure transmitter. The temperature transmitter is fixed downstream of the device for measuring temperature.

[0016] like figure 1 As shown, the device of the present invention, the measuring pipeline is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com