Method for making closed composite partition wall board

A technology of composite partition wall and manufacturing method, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of inconvenient laying of lines and switch sockets, and is not suitable for partition boards, etc., and achieves simple and fast construction, waterproof and moisture-proof performance Good, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

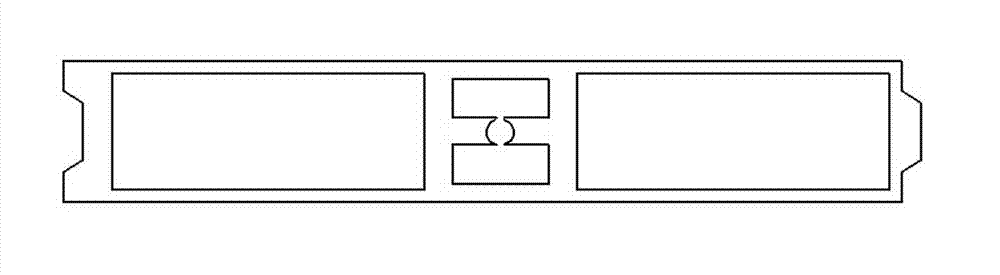

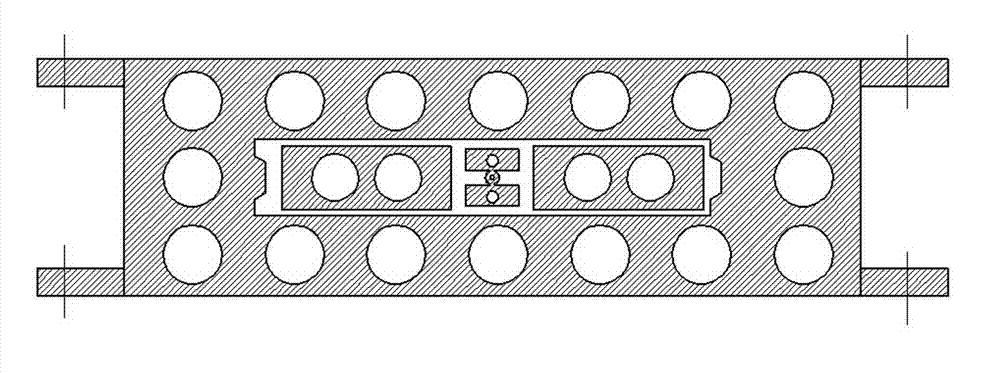

[0019] A method for making a closed composite partition wall panel, comprising the following steps,

[0020] (1) First, make the raw materials for the closed composite partition board shell; the mass parts of each component in the raw materials are 100 parts of PVC, 0.5 parts of wood flour, 0.6 parts of foaming agent, 7 parts of calcium carbonate, and 0.45 parts of PE wax 8 parts, 8 parts of stearic acid, 2.6 parts of stabilizer, 0.2 part of microsilica fume, the raw materials are added in the high-speed mixer according to the above ratio, and the high-speed rotation is mixed evenly to obtain the mixed material;

[0021] (2) Then, extrude the closed composite partition board shell; transport the mixed material to the hopper and enter the extruder cavity, the temperature in the cavity is kept at 161°C, and the mixed material is melted under the above temperature conditions Slurry, as the screw of the extruder rotates, the melted slurry is transported into the integrated shaping...

Embodiment 2

[0024] A method for making a closed composite partition wall panel, comprising the following steps,

[0025] (1) First, make the raw materials for the closed composite partition board shell; the mass parts of each component in the raw materials are 100 parts of PVC, 0.6 parts of wood flour, 0.7 parts of foaming agent, 8 parts of calcium carbonate, and 0.5 parts of PE wax 9 parts, 9 parts of stearic acid, 2.7 parts of stabilizer, 0.3 part of microsilica powder, the raw materials are added in the high-speed mixer according to the above ratio, and the high-speed rotation is mixed evenly to obtain the mixed material;

[0026] (2) Then, extrude the closed composite partition board shell; transport the mixed material to the hopper and enter the extruder cavity, the temperature in the cavity is kept at 163°C, and the mixed material is melted into a material under the above temperature conditions Slurry, as the screw of the extruder rotates, the melted slurry is transported into the i...

Embodiment 3

[0029] A method for making a closed composite partition wall panel, comprising the following steps,

[0030](1) First, make the raw materials for the closed composite partition board shell; the mass parts of each component in the raw materials are 100 parts of PVC, 0.7 parts of wood flour, 0.8 parts of foaming agent, 5 parts of calcium carbonate, and 0.3 parts of PE wax 10 parts, 10 parts of stearic acid, 2.8 parts of stabilizer, 0.1 part of micro-silica fume, the raw materials are added in the high-speed mixer according to the above ratio, and the high-speed rotation is mixed evenly to obtain the mixed material;

[0031] (2) Then, extrude the closed composite partition board shell; transport the mixed material to the hopper, enter the extruder cavity, and keep the temperature in the cavity at 165°C. Under the above temperature conditions, the mixed material is melted into a material Slurry, as the screw of the extruder rotates, the melted slurry is transported into the integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com