Lubricating grease supply system of conveying-type continuous plating device

An electroplating device and supply system technology, which is applied in the direction of engine lubrication, cleaning devices, conveyor objects, etc., to achieve the effect of improving power supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

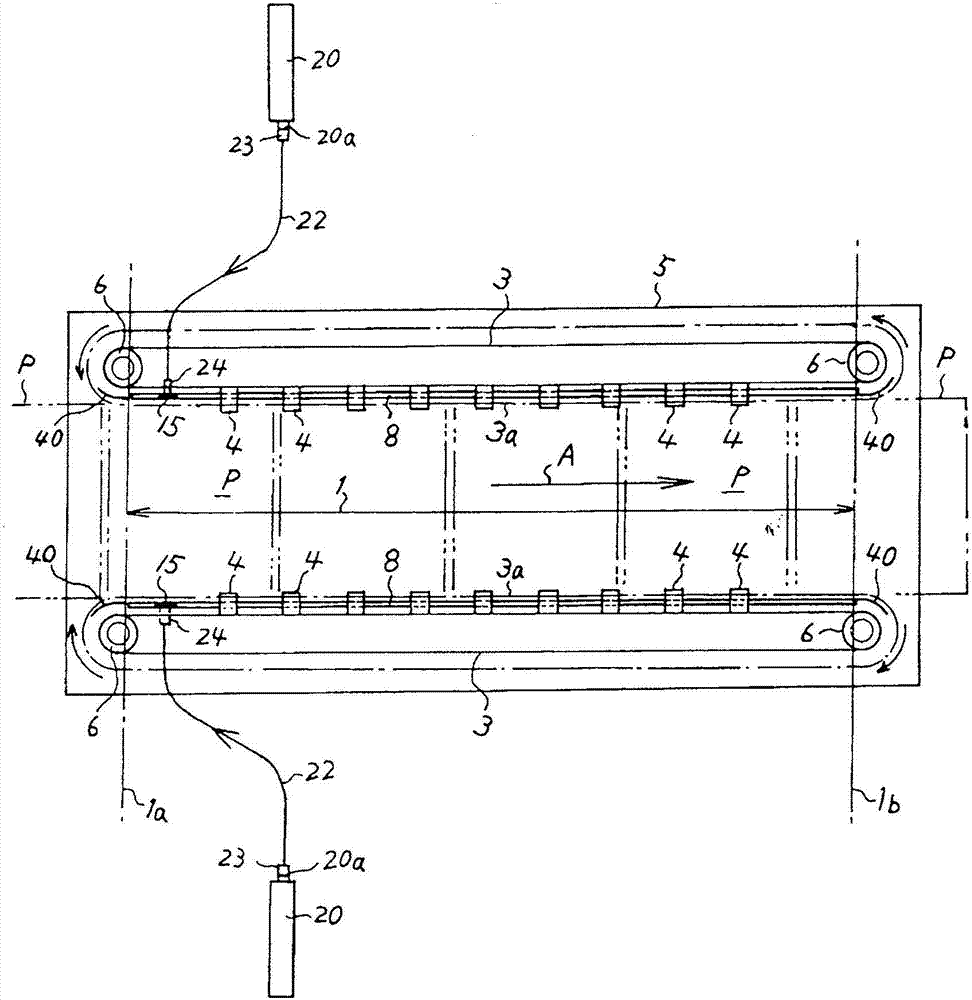

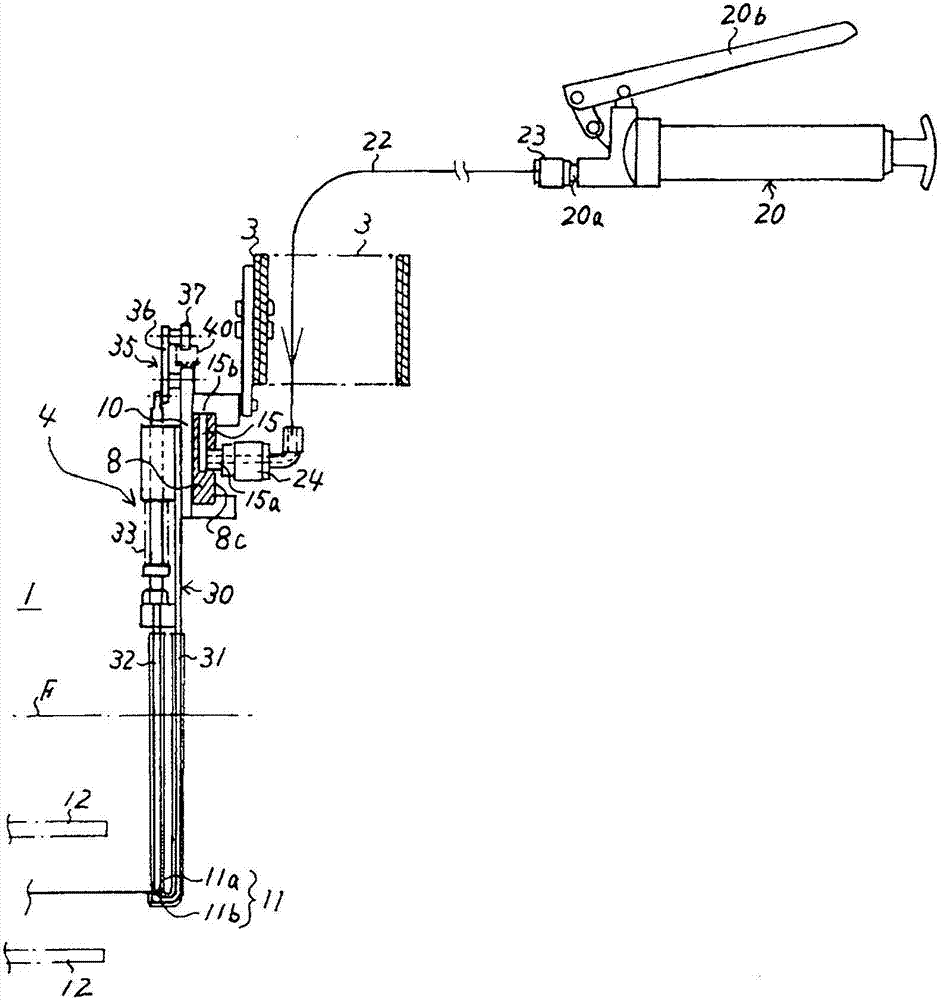

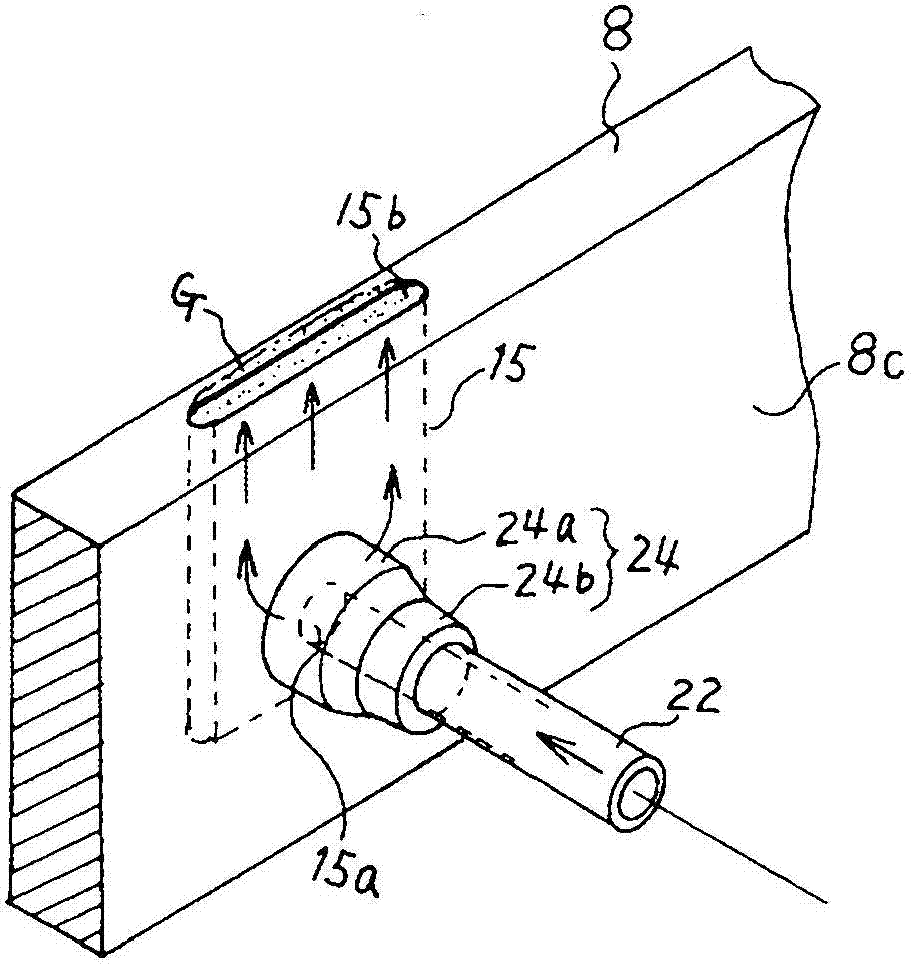

[0028] Next, embodiments of the present invention will be described based on the drawings. figure 1 It roughly represents the whole of the horizontal conveying type continuous electroplating device, figure 2 and image 3 An embodiment showing the main part of the device.

[0029] figure 1 The horizontal conveyance type continuous electroplating apparatus is a device as follows: On both sides of the conveyance path 1 that sandwiches a thin plate-shaped object such as a printed circuit board (hereinafter sometimes referred to as a thin substrate P) P, there are respectively equipped with The conveying parts of the conveying drive belts 3 and 3 that are driven in a circular rotation, are equipped with many clamping tools 4 at equal intervals on the conveying drive belt 3 . A plurality of clamping tools 4 moving on the inner linear drive path portion 3a, 3a clamps the both side edges of the flexible thin plate-shaped object P having parallel side edges from the up and down dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com