A Method for Steadily Controlling the Pickling Quality of Titanium Coils

A technology for stable control and titanium strips, applied in the field of controlling the quality of titanium coil pickling stability, can solve the problems of uncontrollable pickling process speed of titanium coil pickling quality, reduced yield, and unclean cleaning, etc., and is conducive to environmental protection. , Easy to operate, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

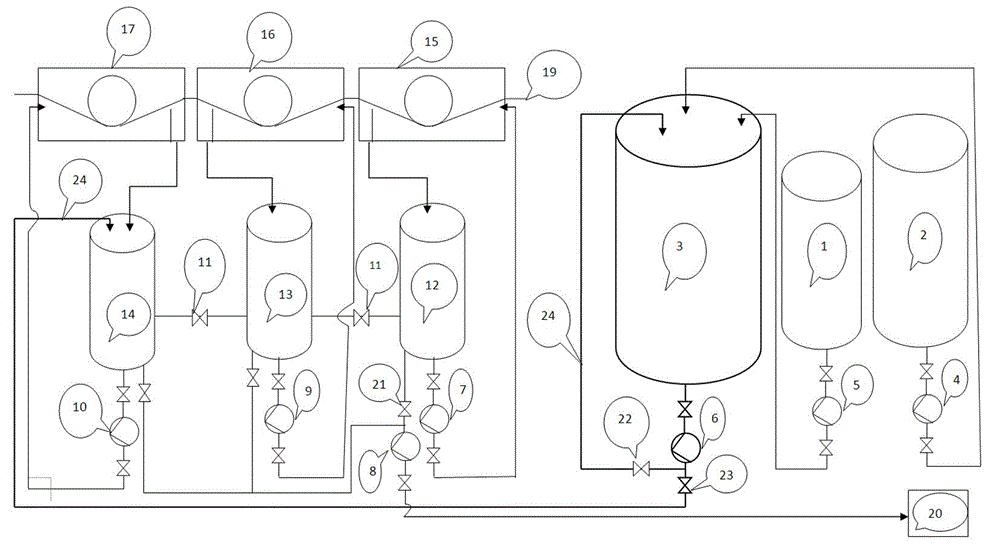

[0023] See figure 1 , a method for stably controlling the pickling quality of titanium coils, the invention comprises the following steps:

[0024] 1) The acid supply and discharge system for the pickling of titanium strip coil 19 includes the acid distribution system and the pickling process section;

[0025] 2) Acid distribution system includes HF tank 1, HNO 3 Tank 2, mixed acid tank 3 and supporting acid pumps 4, 5, 6;

[0026] 3) The pickling process section is divided into three sections, each section includes an acid tank, an acid tank and a set of acid circulation system; the first section includes 1# acid tank 12, 1# acid tank 15 and supporting acid pump 7; the second Section includes 2# acid tank 13, 2# acid tank 16 and supporting acid pump 9; the third section includes 3# acid tank 14, 3# acid tank 17 and supporting acid pump 10.

[0027] 4) The three acid tanks in the pickling section are connected at the lower 1 / 3 of the tank body with connecting pipes, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com