Method for processing pre-leached material of camellia seed through bulking

A camellia seed and pre-leaching technology, which is applied in the production of fat oil/fat and fat production, can solve the problems of poor quality, high solvent consumption, dark color of crude oil, etc., to save cost and space, and improve drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

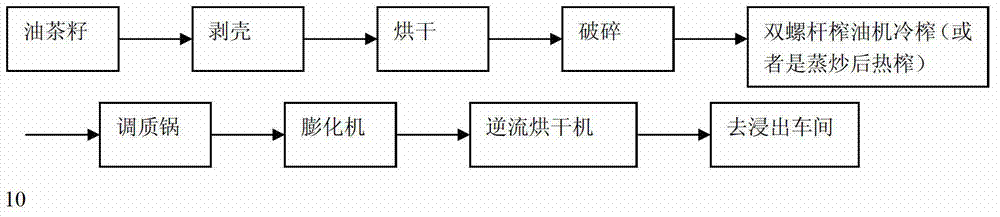

Embodiment 1

[0022] Embodiment 1: After shelling the camellia seed, dry it. The oil content of the dried material is 45% as determined, and the dried moisture is 8%. The dried camellia seed is oil-pressed by a twin-screw cold press. The pre-pressed cake after oil extraction, with a residual oil content of 7.6%, enters the elevator through the scraper, and is tempered through the tempering pot. The first and second layers of the tempering pot are sprayed with direct steam at a pressure of 0.1MPa in sequence. In the third layer of the tempering pot, the temperature is sprayed into hot water above 80°C. The amount of hot water added is based on the material moisture being no more than 14%, and the measured moisture is 12.8%. No hot water is sprayed, and the water content of the discharged material meets the requirements after inspection, and the hot water can be turned off.

[0023] After tempering, the pre-pressed cake enters the frying chamber of the long-screw extruder. When extruding, ad...

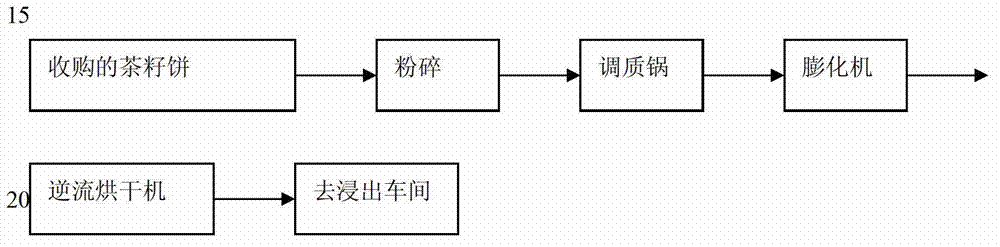

Embodiment 2

[0024] Embodiment 2: The tea seed cake purchased is pulverized, the particle size of pulverized is no more than 2mm, and the oil content of the material is measured to be 42%. After being pulverized and discharged, it enters the elevator through the scraper, and is tempered through the tempering pot. The first and second layers of the tempering pot are sprayed with direct steam at a pressure of 0.1MPa, and the third layer of the tempering pot Spray the hot water with a temperature of more than 80°C at the feed opening, the amount of hot water added is based on the fact that the moisture content of the material is no more than 14%, and the measured moisture content is 13.4%. If you do not spray hot water, the water content of the discharged material meets the requirements after inspection, and you can turn off the hot water.

[0025] The directly purchased tea seed cake after tempering enters the blast chamber of the long-screw extruder. When extruding, add direct steam with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com