Low-temperature phase transition material for storing cold energy and preparation method of low-temperature phase transition material

A low-temperature phase change and cold energy technology, which is applied in the field of composite materials, can solve problems such as poor cold storage capacity, high phase transition temperature of cold storage materials, and large fluctuations in cold energy supply, and achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] (1) Preparation of nanoporous graphite matrix: The nanoporous graphite matrix material is made of flake graphite, suitable oxidant and intercalation agent for intercalation reaction by thermochemical method, and then the nanoporous graphite material is prepared by microwave expansion method. The specific preparation The steps refer to the patented invention (preparation method of nanoporous graphite, patent number: ZL200410052871.4);

[0045] (2) Preparation method of low temperature phase change material for cold energy storage: nanoporous graphite matrix, TiO 2 Mix with the mixture in proportion (wt%) 2~5:98~95, and configure the solution through a high-temperature oil bath.

[0046] (3) Stir fully, mix evenly, let stand, cool to normal temperature, put into cryogenic test box, obtain the low-temperature phase-change material used for cold energy storage after completely solidifying.

[0047] Compositing of nanoporous graphite with nanometer metal matrix materials and ...

Embodiment 1

[0050] A method for preparing shallow-cooled nanoporous graphite and metal-based low-temperature phase-change materials: heptanol and ethyl bromide are selected as low-temperature phase-change materials.

[0051] Weigh 30 grams of heptanol and 6 grams of bromoethane into a 0.2L container, slowly add 1.5 grams of nanoporous graphite, 2.0 grams of TiO 2 , after fully absorbing, place the nanoporous graphite, titanium dioxide / heptanol, bromoethane phase change energy storage composite material in an ultrasonic oscillator at 150~160°C and stir for 10 minutes, and place it in an airtight container after it is mixed evenly. Put it in a cryogenic test box at -60°C, and after it is completely solidified, you can get a nanoporous and nanometal-based energy storage composite material for storing cold.

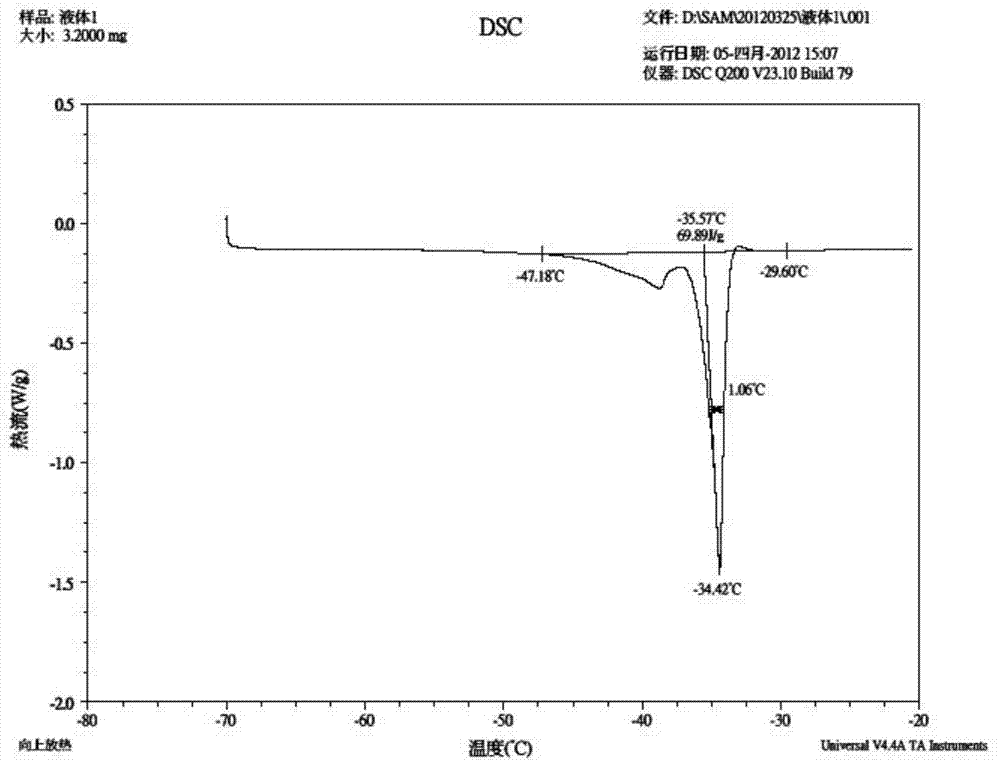

[0052] figure 1 It is the DSC figure of embodiment 1. The peak solidification phase transition temperature is -50.6 degrees, and the latent heat value of phase transition is 68.9~90J / ...

Embodiment 2

[0054] A method for preparing a nanometer metal-based low-temperature phase-change energy storage composite material: bromoethane and ethylene glycol are selected as low-temperature phase-change materials.

[0055] Weigh 13g of ethylene glycol and 7g of bromoethane into a 0.2L container, slowly add 0.5g of silicon dioxide, 0.2g of 80 Sipan, and after fully absorbed, phase change storage of secondary silica / bromoethane and ethylene glycol The energy composite material is placed in an ultra-deep wave oscillator at 150-160°C and stirred for 10 minutes. After it is mixed evenly, it is placed in a closed container and placed in a -60°C cryogenic test chamber. After being completely solidified, the nanometer metal matrix energy storage composite material for storing cold is obtained.

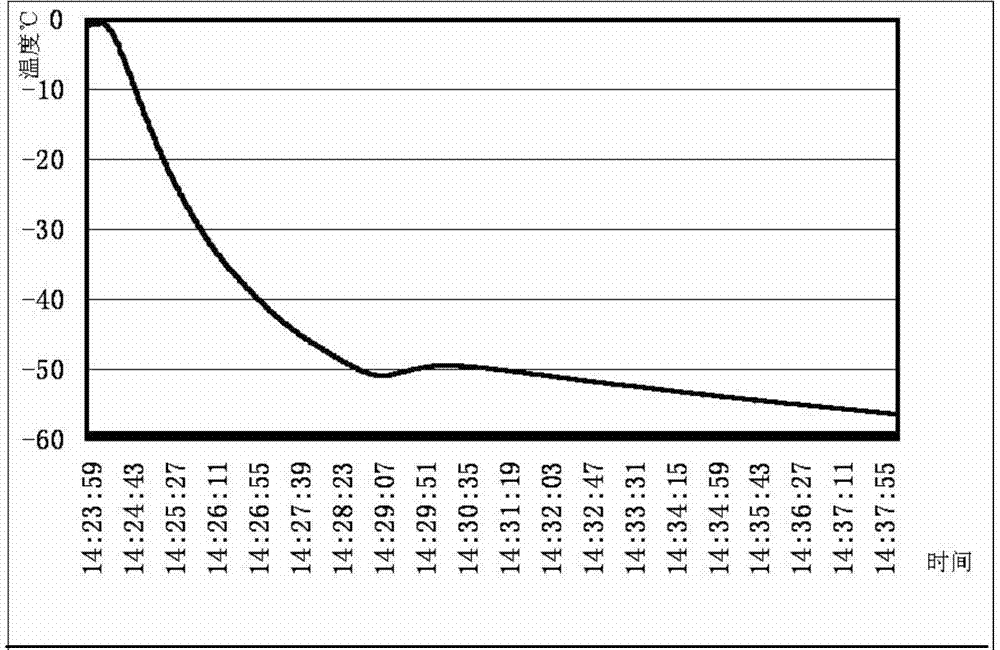

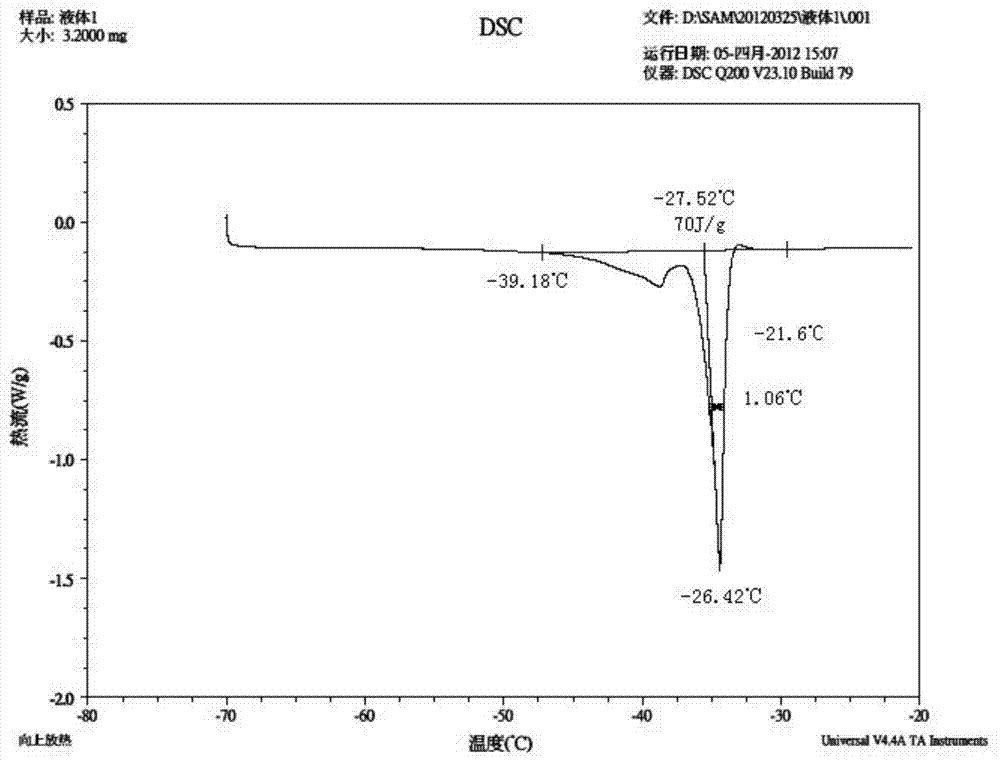

[0056] image 3 It is the DSC figure of embodiment 2. Its phase transition latent heat value is 70-83J / g, and its solidification phase transition temperature is -42 degrees. Figure 4 It is the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change latent heat value | aaaaa | aaaaa |

| Phase change latent heat value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com