Modified cold-stirred and cold-spread room temperature bitumen and preparation method thereof

A normal temperature asphalt and bitumen technology, used in building thermal insulation materials, building components, buildings, etc., can solve the problems of reduced adhesion between asphalt and fine aggregates, complex treatment of rubber-modified asphalt, and complex preparation processes, and achieve high plasticity. , low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

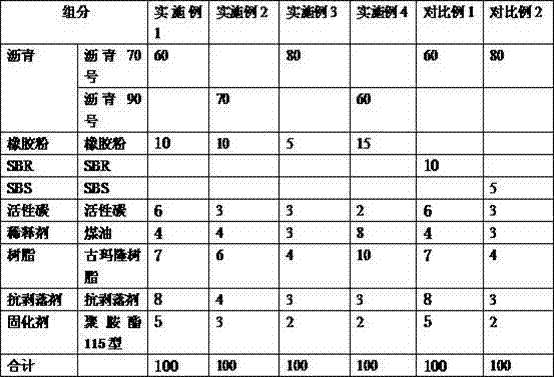

Examples

Embodiment 5

[0058] Example 5 Performance Test Comparison

[0059] Test the properties of the asphalt materials in Examples 1-4 and Comparative Examples 1-2, such as high-temperature performance, low-temperature performance, ease of construction, segregation, environmental impact, energy consumption, etc. The testing methods are all conventional methods in this field. The asphalt of the examples and the comparative examples were mixed with the fine aggregate to form a mixture, and the performance test was carried out according to the performance measurement experiment of JTG E-20-2011 [Sub-Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering]. The results are shown in Table 1 below:

[0060] performance Example 1 Example 2 Example 3 Example 4 Comparative example 1 Comparative example 2 high temperature performance excellent excellent excellent excellent poor it is good high temperature performance excellent excellent ...

Embodiment 6

[0061] Example 6 Marshall stability test

[0062] According to JTG E-20-2011 [highway engineering asphalt and asphalt mixture sub-test regulations] test the Marshall stability test of the mixture of the asphalt material of Examples 1-4 and the asphalt material of Comparative Examples 1-2. Keep the temperature at the specified temperature for 12 hours, and measure the stability. The results are shown in Table 2 below:

[0063] Table 2: Stability test results (unit KN)

[0064] The data in Table 2 show that the stability of the modified normal temperature asphalt of the present invention is better than or equal to that of SBS or SBR modified asphalt.

Embodiment 7

[0065] Example 7 technical indicators

[0066] According to the provisions of JTG E-20-2011 [Sub-Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering], parameters such as penetration, penetration index, ductility, elastic recovery, softening point, and kinematic viscosity were measured. The data is as follows:

[0067] performance Penetration (25°C, 100g5s) 0.1mm The penetration index is not less than 15℃ ductility 5cm / min Softening point ℃ Elastic recovery at 25°C Kinematic viscosity Pa.s Example 1 60 0.23 50 56 75 2.5 Example 2 86 -0.20 55 57 60 1.8 Example 3 62 0.20 40 53 70 2.3 Example 4 76 -0.10 60 60 78 2.0 Comparative example 1 62 -0.30 35 50 65 2.0 Comparative example 2 63 -0.52 38 54 58 1.8 No. 70 asphalt 64 -0.88 150 49 - - No. 90 asphalt 93 -1.23 128.3 45.5 - - testing method T0604 T0604 T0605 T0606 T0662 T0625

[0068...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com