Method and device for pretreating thickened oil refining sewage

A technology for refining and chemical sewage and pretreatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (super) heavy oil sewage pretreatment technological process

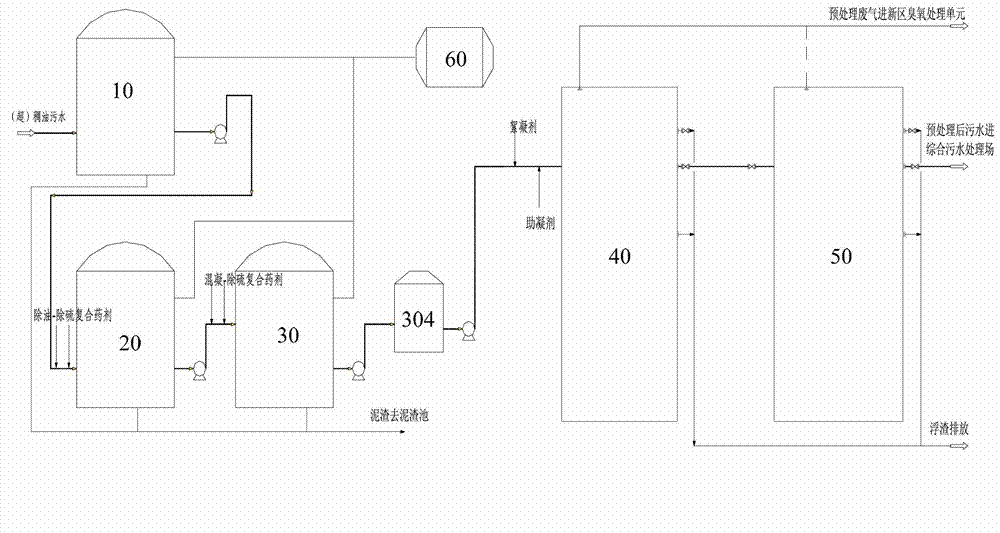

[0044] seefigure 1 , the device for the pretreatment of heavy oil refinery sewage of the present invention comprises a homogeneous settling tank 10, a demulsification and oil removal tank 20, a coagulation settling tank 30, a primary ozone oxidation device 40 and a secondary ozone catalytic oxidation device 50 arranged in sequence , the homogeneous settling tank 10, the demulsification and oil removal tank 20, the coagulation settling tank 30, the primary ozone oxidation device 40 and the secondary ozone catalytic oxidation device 50 are sequentially connected through sewage pipelines. In addition, the heavy oil refinery sewage pretreatment device is also provided with a waste oil tank 60 for collecting floating oil from the homogeneous settling tank 10 , the demulsification tank 20 and the coagulation settling tank 30 . A buffer tank 304 is provided between the coagulation settling tank 30 and t...

Embodiment 2

[0052] Embodiment 2 Ozone high-pressure catalytic oxidation device

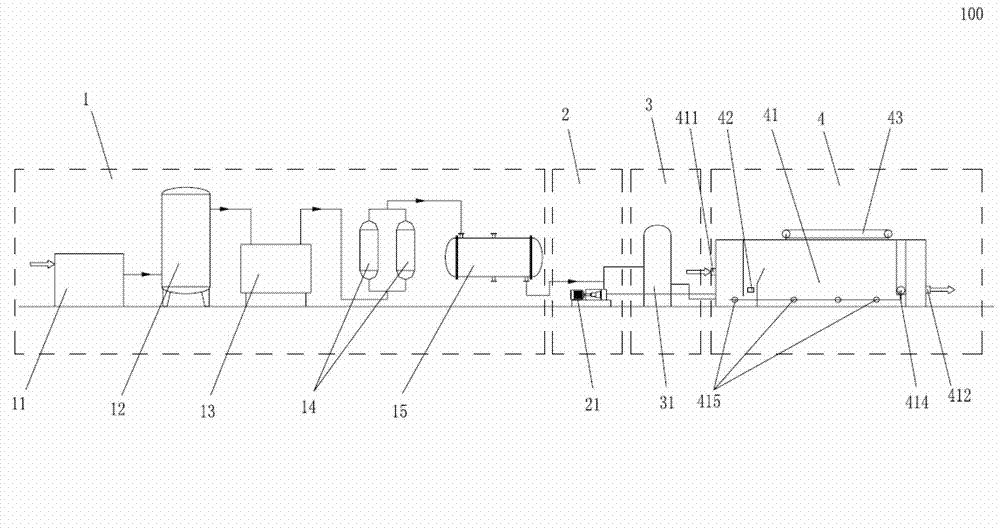

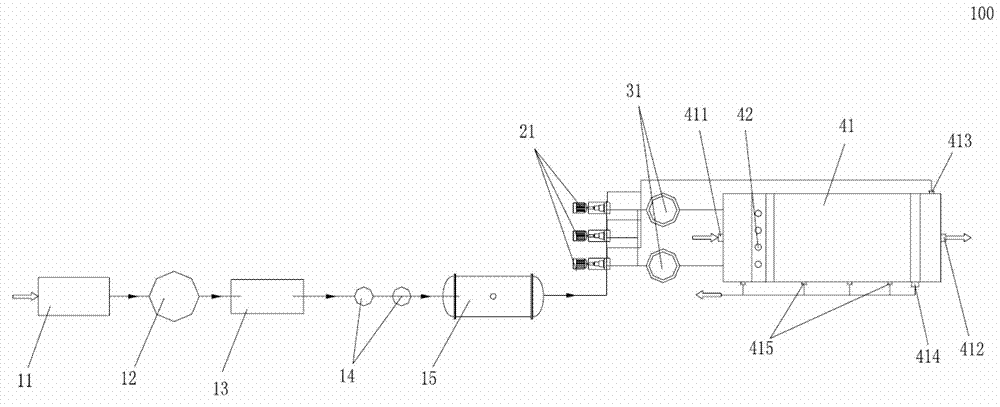

[0053] The structures of the first-stage ozone oxidation device 40 and the second-stage ozone catalytic oxidation device 50 used in the device process of Example 1 are basically the same, except that the secondary ozone catalytic oxidation device is filled with a catalyst. Specifically, the structure of the primary ozone oxidation device and the secondary ozone catalytic oxidation device is as follows figure 2 , image 3 Described.

[0054] Such as figure 2 , image 3 As shown, the ozone (catalytic) oxidation device 100 (first-stage ozone oxidation device 40, secondary ozone catalytic oxidation device 50) includes an ozone generation system 1 connected in sequence by pipelines, an ozone dissolved gas water generation system 2, an ozone (catalysis) Oxidation system 3 and oxidation reaction separation system 4; Ozone generation system 1 is connected with ozone dissolved air water generation system 2 entra...

Embodiment 3

[0060] The preparation of embodiment 3 ozone heterogeneous catalysts

[0061] Weigh the coarse porous silica gel (the average pore diameter of the coarse porous silica gel is 8.0~10.0nm, the specific surface area is 300~400m 2 / g, pore volume 0.8 ~ 1.0ml / g;) 18 grams was dried at 110°C for 10 hours, added 5% hydrogen peroxide solution, soaked for 14 hours, taken out, dried in the shade, and set aside; soak the above-mentioned coarse-pored silica gel in equal volume Stay in the mixed solution of 6 grams of manganese nitrate and 4 grams of ferric nitrate, keep for 20 hours, dry at 110°C for 10 hours, and then calcined at 500°C for 5 hours to obtain a catalyst for catalytic oxidation treatment of sewage.

[0062] Figure 4 , Figure 5 and Figure 6 They are respectively the nitrogen adsorption and desorption curve, the pore size distribution curve and the transmission electron microscope diagram of the ozone heterogeneous catalyst prepared in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com