Method for performing carbon coating modification on nano-powder by adopting water-soluble polymer

A technology of water-soluble polymers and nano-powders, which is applied in the direction of electrical components, battery electrodes, circuits, etc., to achieve the effects of low production cost, high yield, and enhanced performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

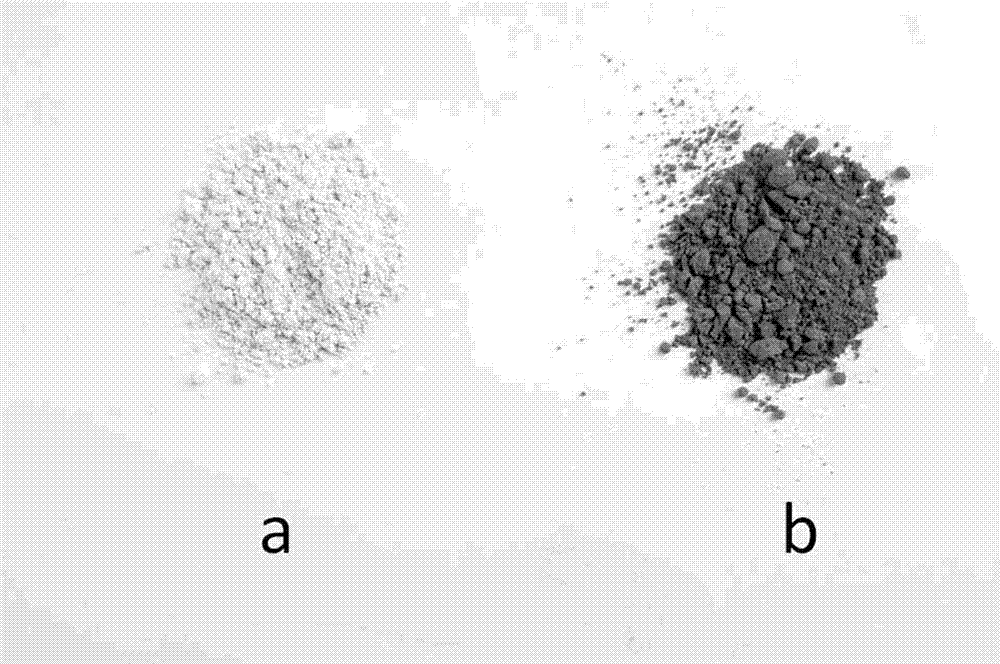

[0030] Weigh 2g of soluble starch, 0.5g of carboxymethyl starch, 1g of glucose, 0.5g of PVP and 60.08g of commercial nano-silicon dioxide, respectively, and add them to a mixed solution of 30mL of pure water and 10mL of ethanol in sequence, stir well and then filter with suction. Vacuum drying at 80°C for 5 hours to obtain the precursor powder. The precursor was annealed at 300°C for 3 hours in a 99% nitrogen atmosphere, and then annealed at 700°C for 6 hours to obtain silicon oxide nanopowder with good carbon coating. figure 1 Among them, a is the commercial silica raw material, and b is the carbon-coated silica obtained from the reaction.

Embodiment 2

[0032]Weigh cross-linked hydroxypropyl tapioca starch and glucose according to the mass ratio of 1:3, and mix them evenly. Take 1g, 2g, and 5g of the above mixture, mix them with 40g of commercial nano-titanium dioxide respectively, and stir them with 20mL of pure water respectively. Filter, vacuum dry at 80°C for 5 hours to obtain three precursor powders; anneal the precursor in 99% nitrogen atmosphere at 300°C for 3 hours, then anneal at 700°C for 6 hours, and finally obtain three carbon-coated nano-titanium dioxide in turn Powder. like figure 2 as shown, figure 2 a is a commercial nano-titanium dioxide raw material, figure 2 b. figure 2 c. figure 2 d is the carbon-coated nano-titanium dioxide obtained by adding 1 g, 2 g, and 5 g of the water-soluble polymer, respectively.

Embodiment 3

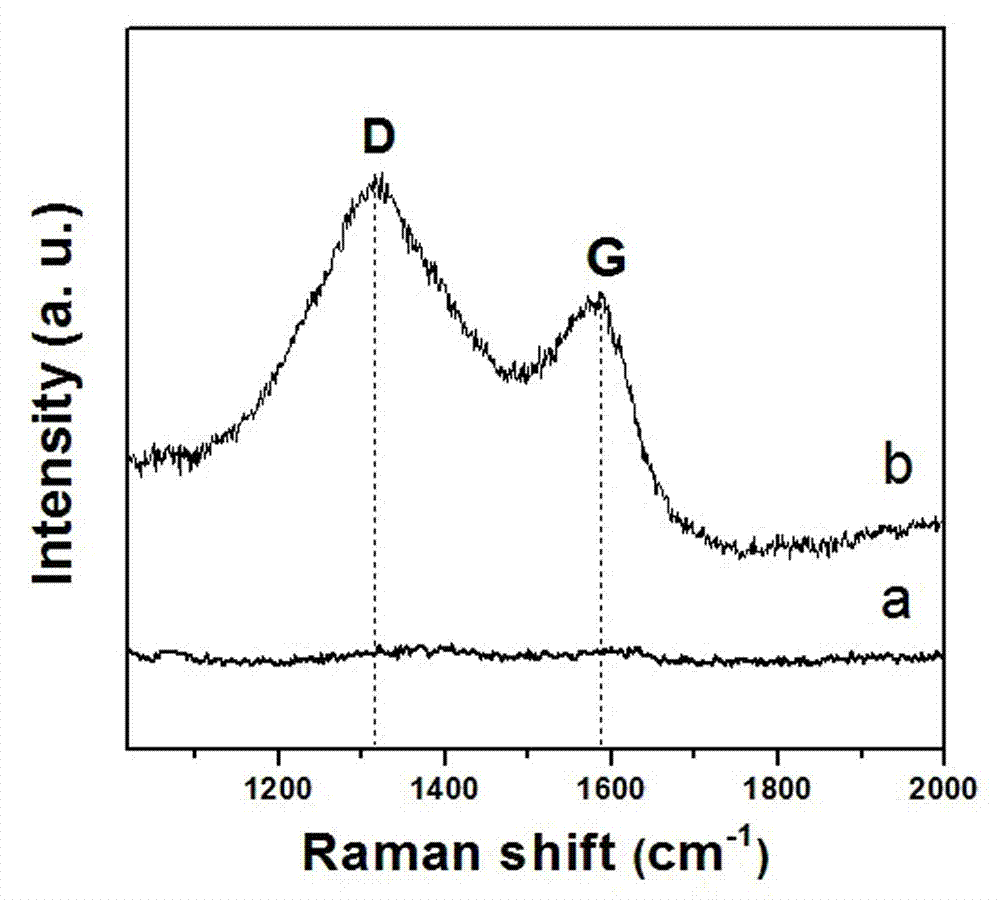

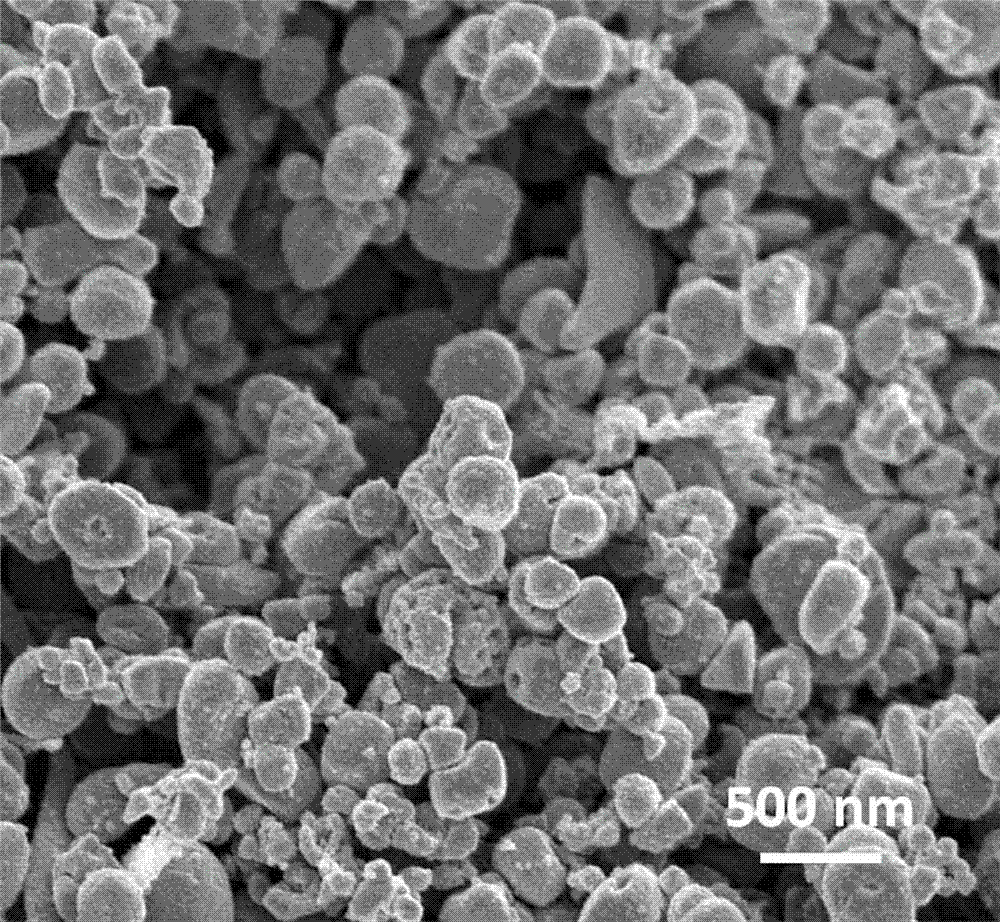

[0034] Weigh 1g of soluble starch, 2.5g of glucose, 0.2g of PVP and 39.5g of lithium ferrous phosphate, add them into a mixed solution composed of 15mL of water and 5mL of ethanol, stir them evenly, filter them with suction, and dry them under vacuum at 80°C for 5 hours to obtain the precursor The precursor was annealed at 300°C for 3 hours in a 99.9% nitrogen atmosphere, and then annealed at 600°C for 6 hours to obtain lithium iron phosphate nanopowder with good carbon coating. image 3 Lithium iron phosphate before carbon coating ( image 3 a) and carbon-coated lithium iron phosphate ( image 3 b) Raman test chart, it can be clearly seen image 3 There is a carbon component in b. By comparing the G peak and D peak, it can be seen that there is no graphite characteristic peak before carbon coating, and the degree of carbon graphitization in the product after carbon coating is relatively high, which is conducive to improving the conductivity of the material. Scanning electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com