Point contact type diode

A diode and point contact technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problem of poor forward and reverse characteristics of point contact diodes, no display of working parameters of point contact diodes, and inability to use large currents And rectification and other issues, to achieve the effect of cheap price, simple structure, convenient and correct use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

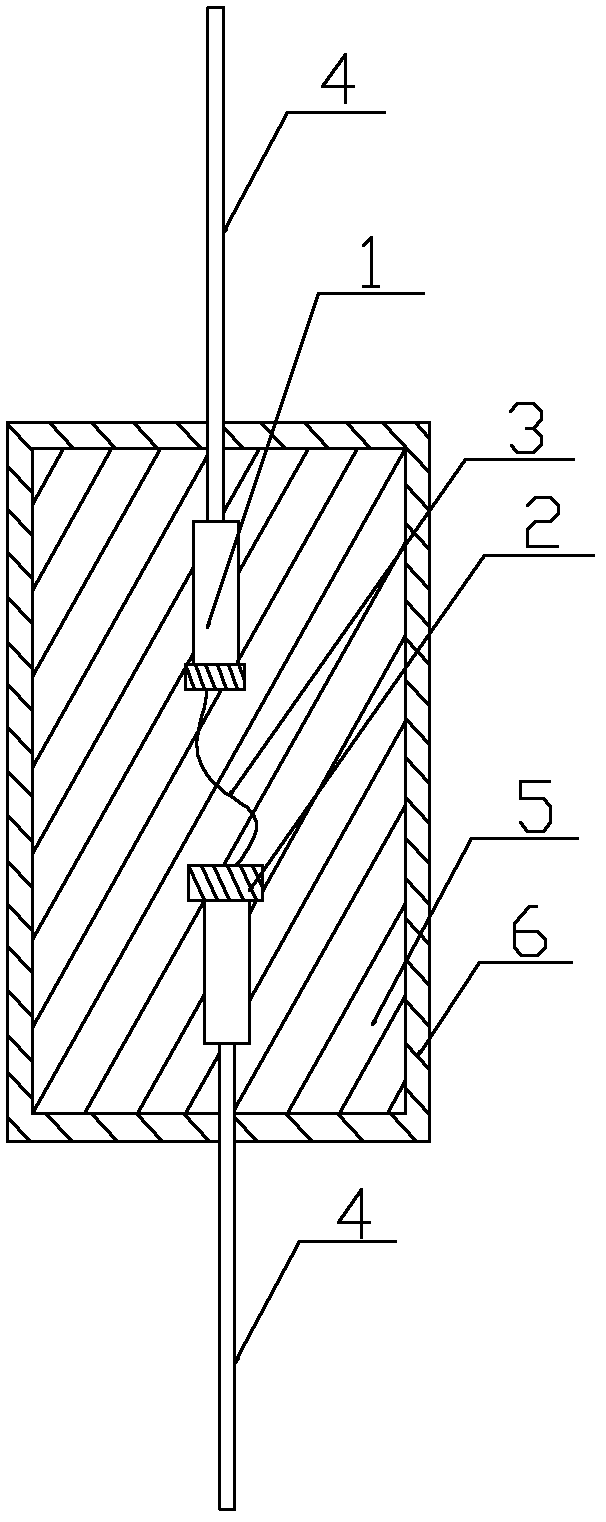

[0012] Such as Figure 1~2 The shown point-contact diode includes a diode body 1. The diode body 1 presses a contact wire 3 on a single chip 2, and a lead wire 4 is soldered to the other ends of the single chip 2 and the contact wire 3 respectively. Chip 2, contact wire 3, lead wire 4 welded with single chip 2 and contact wire 3 are partly plastic-sealed in epoxy resin tube 5, and epoxy resin tube 5 is coated with a layer that can clearly show the working parameters of diode body 1 Coating6.

[0013] The raw material of coating 6 is UV-curable ink, which can be cleaned by freon, alcohol, isopropanol and similar solvents, and the coating will not peel off.

[0014] Inspired by the above-mentioned ideal embodiment according to the present invention, throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com