Frequency conversion speed control stable line feed control method of coke oven heavy load locomotive

A heavy-duty locomotive, frequency conversion speed regulation technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as difficulties and large positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

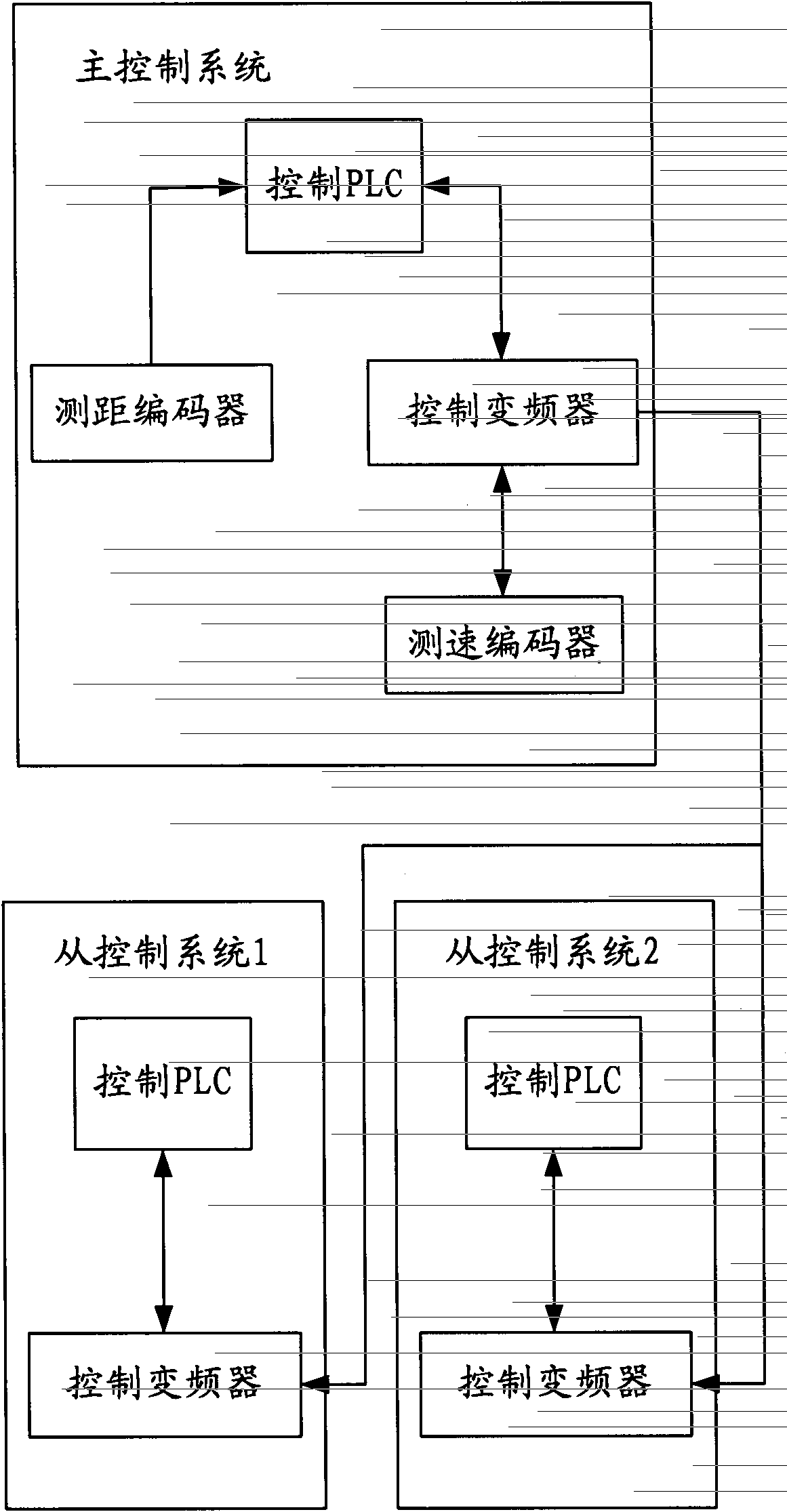

[0017] The coke oven heavy-duty locomotive control method for smooth running with frequency conversion and speed regulation in this embodiment is based on figure 1 The shown set of main control system and several sets of slave control systems are realized. The main control system includes: control PLC, distance measuring encoder (using incremental photoelectric encoder), control frequency converter connected with locomotive travel motor, and The speed measuring encoder (incremental photoelectric encoder) is coaxially connected to the output shaft of the locomotive running motor. The distance measuring encoder, control PLC, control frequency converter, and speed measuring encoder are connected in sequence. The control inverter connected to the locomotive running motor and controlled by the control PLC, the control inverter of the slave control system adopts the torque control operation mode, and the output torque of the inverter controlled by the main control system is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com