Multi-robot logistics warehousing system based on bus mode and control method thereof

A warehousing system and multi-robot technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of low safety and reliability, complex coordination and control, and achieve the effect of high reliability and reduction of communication risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

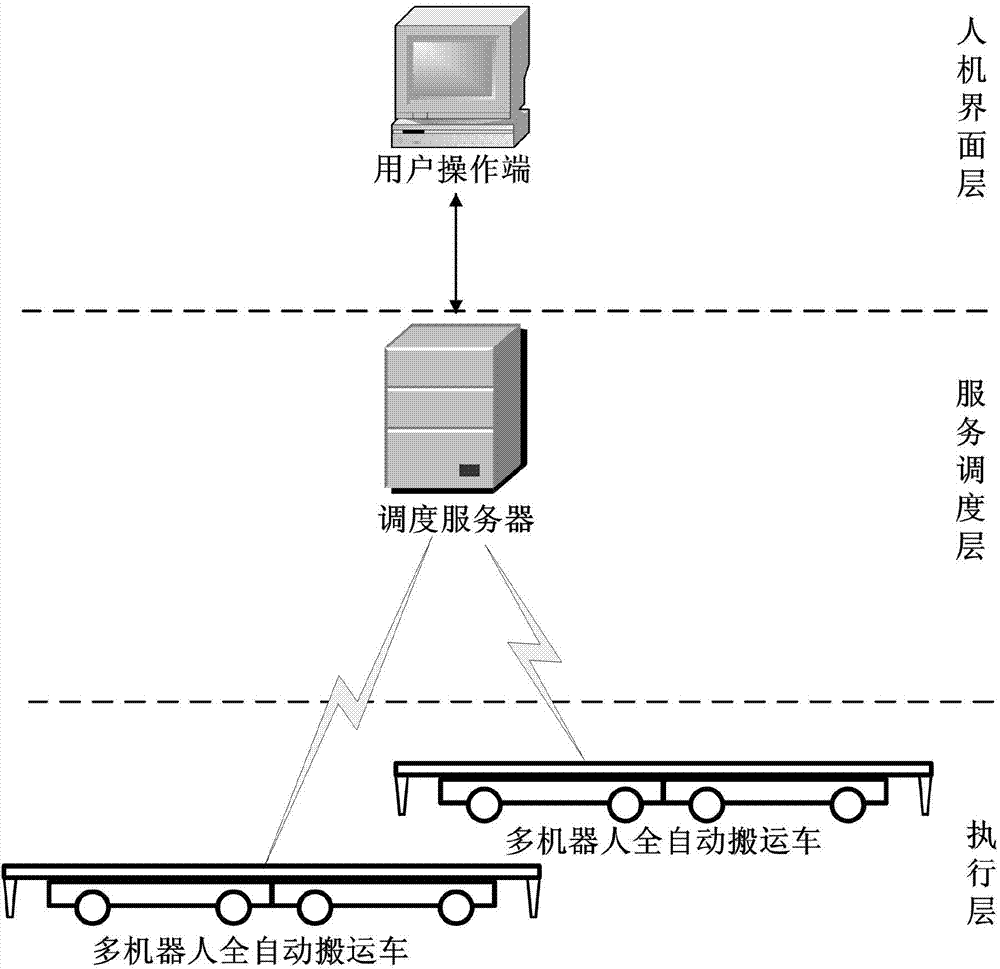

[0035] A bus-based multi-robot logistics storage system includes a warehouse and an intelligent storage control system. The warehouse can be a single-storey warehouse or a multi-storey warehouse. The goods in the warehouse are stored on pallets, and vehicle guide signs are laid on the ground of the warehouse; if the warehouse is a multi-storey warehouse, between each storey There is an elevator. like figure 1 As shown, the intelligent storage control system described is a three-layer architecture system, including a user operation terminal at the man-machine interface layer, a dispatch server at the service dispatch layer, and a multi-robot automatic transport vehicle at the execution layer. The network is connected with the user operation terminal for two-way communication, and the dispatch server realizes the access control function of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com