A bridge elbow joint of a spool and a bridge elbow

A technology for crossing bridge bends and elbows, applied in the direction of electrical components, etc., can solve problems such as failure of bending pipes, cracking or breaking of pipes, labor-intensive problems, etc., to achieve the effects of easy search and use, improved production efficiency, and increased applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

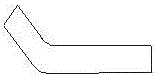

[0027] Such as figure 1 As shown in FIG. 1 , a bridge-crossing elbow of a line pipe is formed by connecting a straight section and an inclined section.

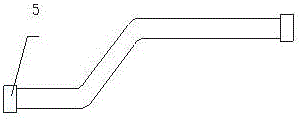

[0028] At least one port of the bridge-crossing elbow is provided with a socket female interface 5, and the inner diameter of the socket socket 5 is adapted to the outer diameter of the bridge-crossing elbow pipe.

[0029] The bridge elbow is provided with a mark showing the type and size of the bridge elbow.

[0030] The included angle between the straight section and the inclined section is an obtuse angle.

[0031] The bridge crossing elbow is formed by connecting a straight section and an inclined section at the ends, and the straight section is located on the left side of the inclined section.

Embodiment 2

[0033] The invention provides a bridge-crossing elbow of a line pipe, such as figure 2 As shown, the bridge crossing elbow is formed by connecting an inclined section and a straight section at the end, the straight section is located on the right side of the inclined section, and the angle between the straight section and the inclined section is an obtuse angle.

[0034] The bridge elbow is provided with a mark showing the type and size of the bridge elbow.

[0035] In this embodiment, the two ports of the bridging elbow are not provided with socket female interfaces.

[0036] Such as Image 6 As shown, the bridge elbows of Embodiment 1 and Embodiment 2 are connected to form a Z-shaped elbow.

[0037] Such as Figure 7 As shown, the bridge-crossing elbow of the line pipe in embodiment 1 and the bridge-crossing elbow of embodiment 2 are rotated 90 degrees and connected to each other to form a 90-degree elbow.

Embodiment 3

[0039] The present invention provides a kind of bridge crossing elbow of line pipe, the difference between embodiment 3 and embodiment 1 is, as image 3 As shown, the bridge crossing elbow is formed by connecting end to end with two straight sections and an inclined section located in the middle of the straight sections, and the two straight sections are located on both sides of the inclined section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com