Indoor test system and test method for seepage characteristics of jointed rock mass

A fractured rock mass, laboratory test technology, applied in the direction of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc. Detailed description of rock mass fracture network, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

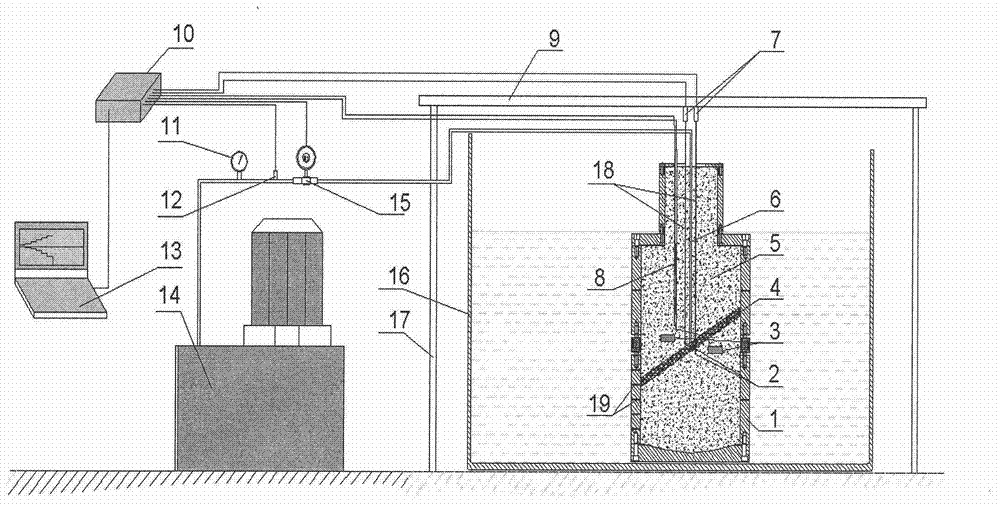

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] See figure 1 , one An indoor test system and method for seepage characteristics of fractured rock mass. In the laboratory, similar materials are used to artificially simulate cracks according to the conditions of cracks on site, and the distribution characteristics of rock mass cracks are studied through crack description, measurement and analysis. Select specific fractures for experimental research, and adjust the dip angle grouping according to the structural plane of the fractured rock mass.

[0032] The minimum splitting pressure in the fracture area is determined according to the high pressure water data of the drilled holes on site. So as to determine the classification standard of high-pressure hydraulic test, the general pressure series is 7-10.

[0033] The indoor test device for seepage characteristics of fractured rock mass has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com