Smart lifting jack verification indication device based on embedded platform and verification method thereof

A technology of indicating devices and jacks, which is applied in the field of automatic measurement and verification of jacks, can solve problems such as complicated operations, inability to conduct man-machine dialogue, inconvenient installation, etc., and achieve the effects of fully automated intelligence, compact hardware and energy saving, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

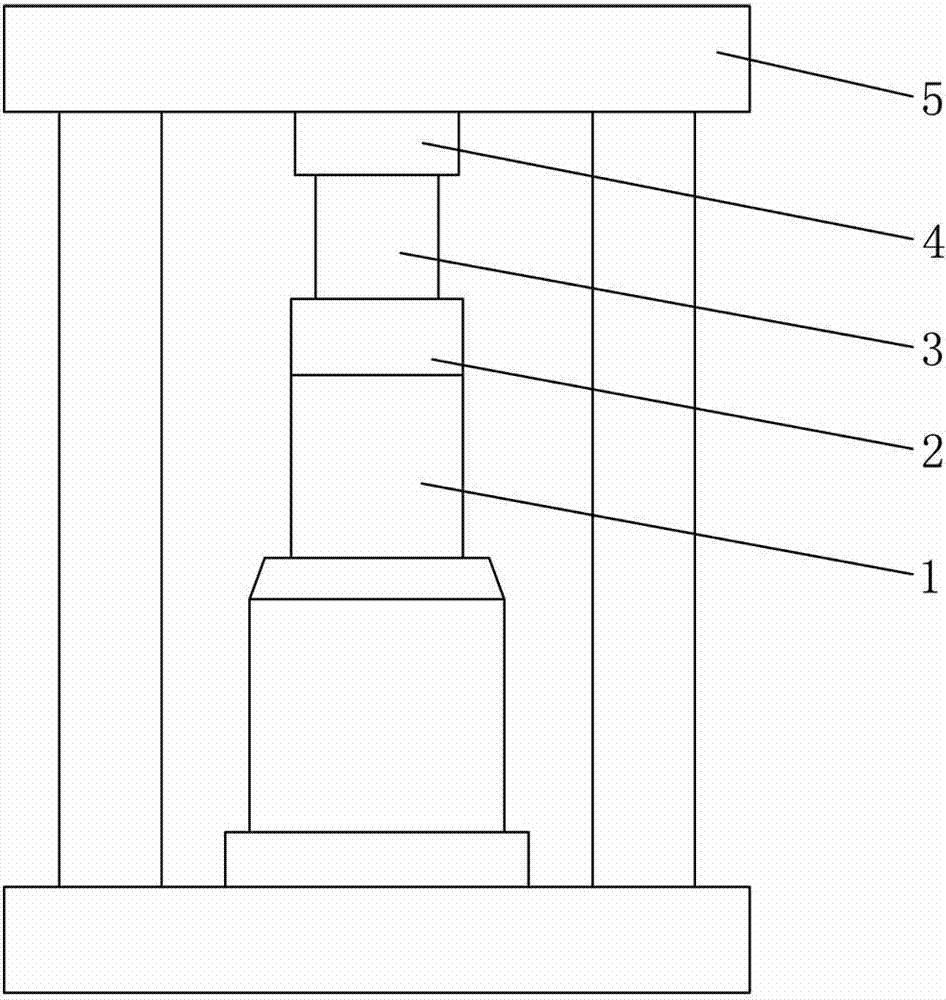

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

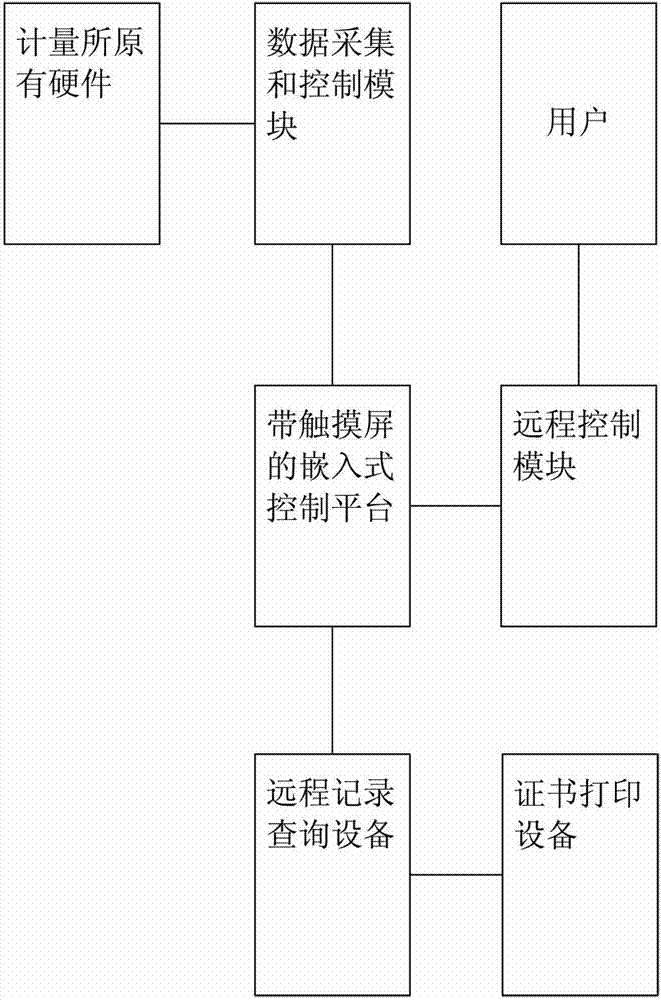

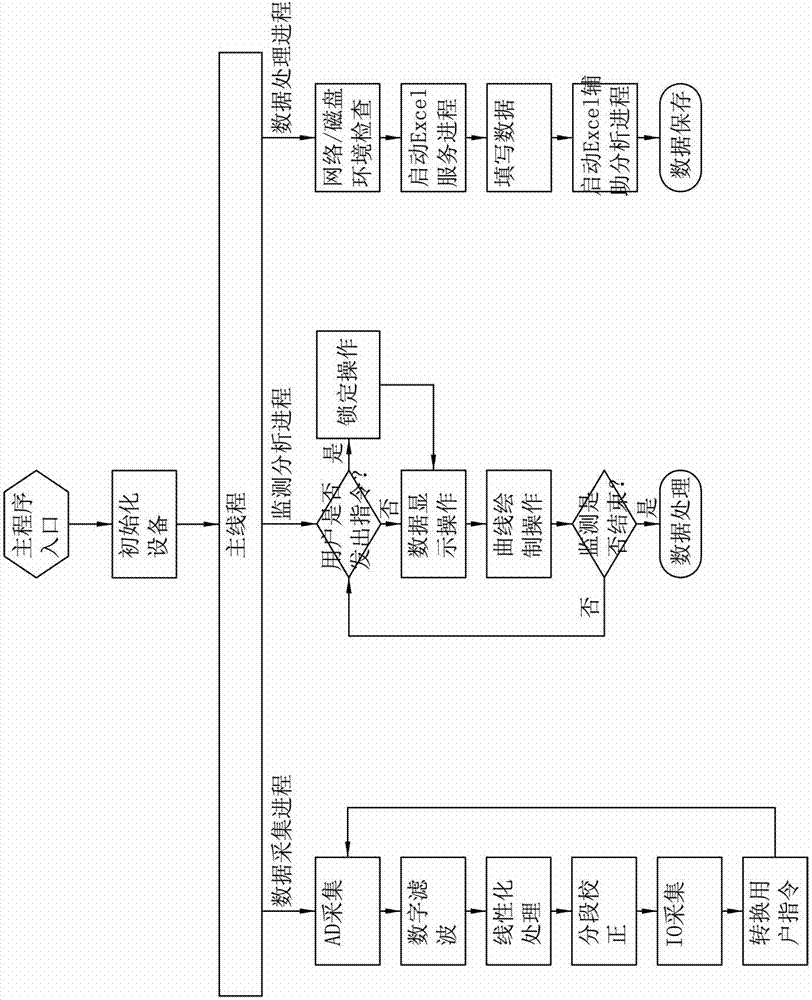

[0050] Such as figure 1As shown, an intelligent jack verification indicator device based on an embedded platform, including a standard dynamometer (original hardware, including sensors, etc.), a data acquisition and control module, an embedded control platform and a remote control module; data acquisition and The control module is electrically connected between the embedded control platform and the standard dynamometer, responsible for receiving the force value analog signal of the standard dynamometer and the remote control module digital signal of the remote control module, and amplifying the force value analog signal After processing and analog-to-digital conversion, it is sent to the embedded control platform; the embedded control platform is an embedded control platform with a touch screen (the core part of the entire system), which is responsible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com