Combustor refractory lining prefabricated building block for cement kiln, production method and application of combustor refractory lining prefabricated building block

A burner and refractory lining technology is applied in the application field of refractory materials, which can solve the problems of short service life of the burner refractory lining body and good use effect, and achieves improved thermal shock resistance stability, rapid construction and replacement, and improved high-temperature thermal state. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

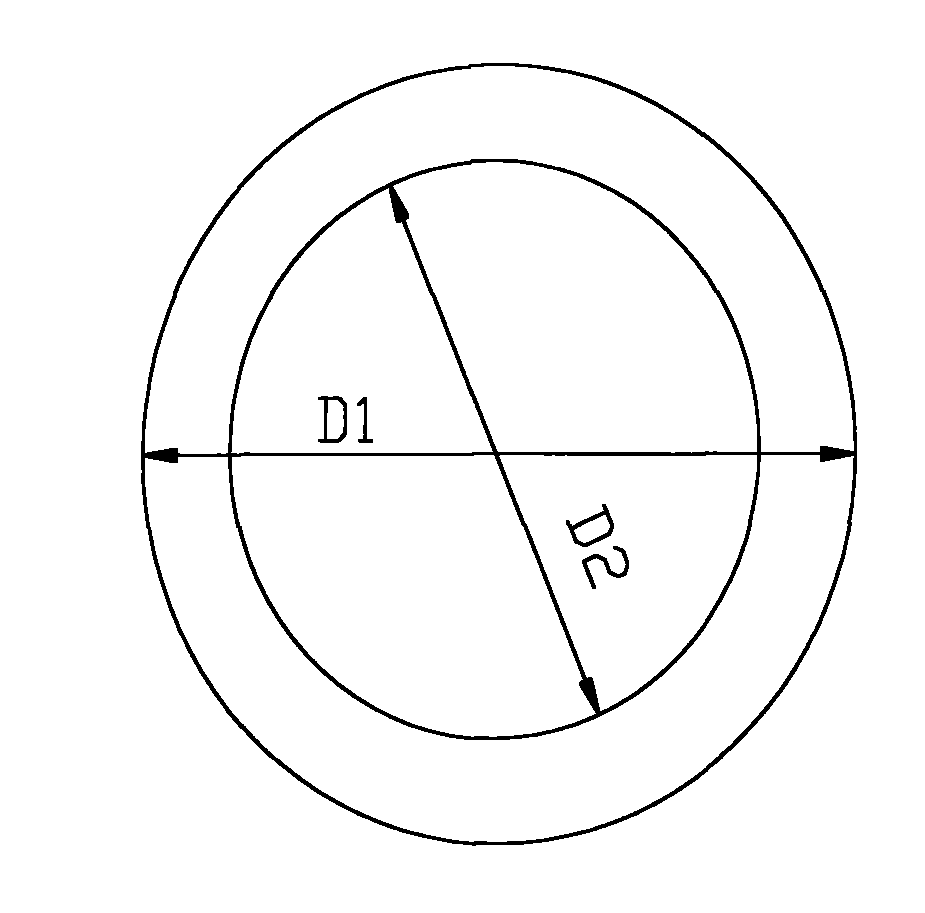

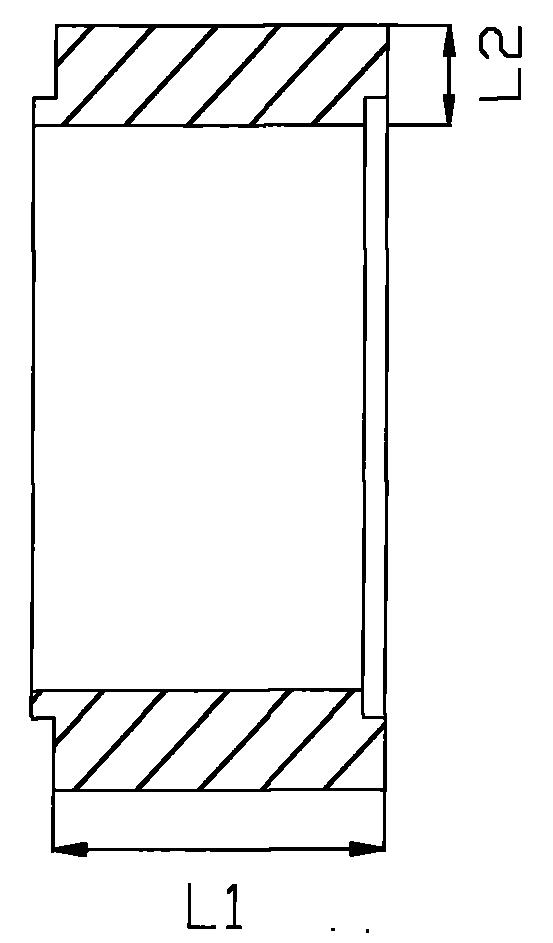

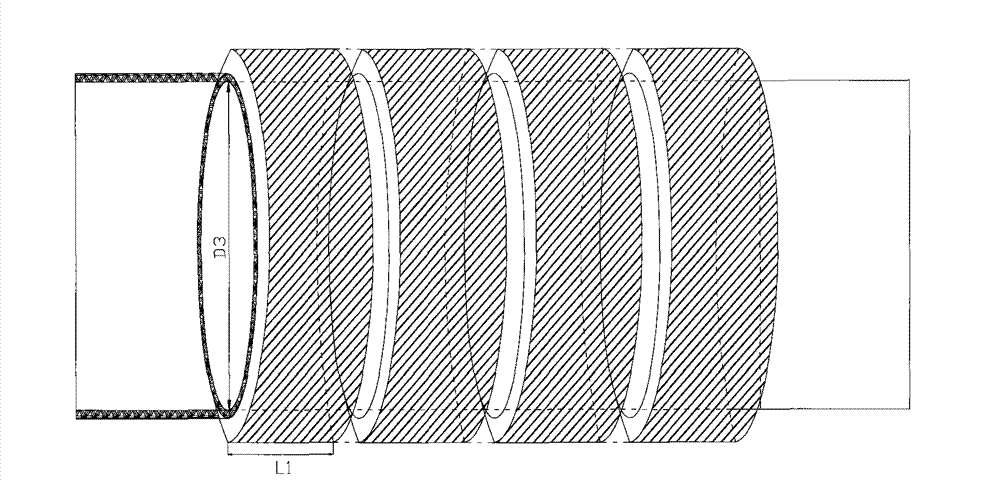

[0021] The building body is made by using the aforementioned wear-resistant castable. Burner D3=600mm, L=5715mm. There are a total of 19 buildings. It should be pointed out that the first building unit of the burner head has no boss, and the last one has no groove. The parameters of the first 18 structural units are: length L1=300mm, thickness of refractory body 80mm, outer diameter D1=760mm, inner diameter D2=600mm, front-end boss height of unit structure 20mm, width 20mm, back-end groove height 22mm, Add the groove width at the rear end to 20mm. Except for the length L1=315mm, the parameters of the 19th structural unit are the same as the first 18 parameters. During construction, lay a high-temperature ceramic fiber blanket on the first layer close to the burner, with a thickness of 2mm, tie it with iron wires, and then put each structural unit on the burner, and insert the boss of the latter structural unit into the previous structural unit The 19 building units are conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com