Small Wave Flame Disturbance Extended Combustion Device

A combustion device and flame technology, which is applied in the field of wavelet type flame disturbance expansion combustion device, can solve problems such as unfavorable rotating airflow, poor adaptability of coal types, and poor coal seam ignition conditions, and achieves improved ignition conditions, increased flue gas temperature, and improved adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

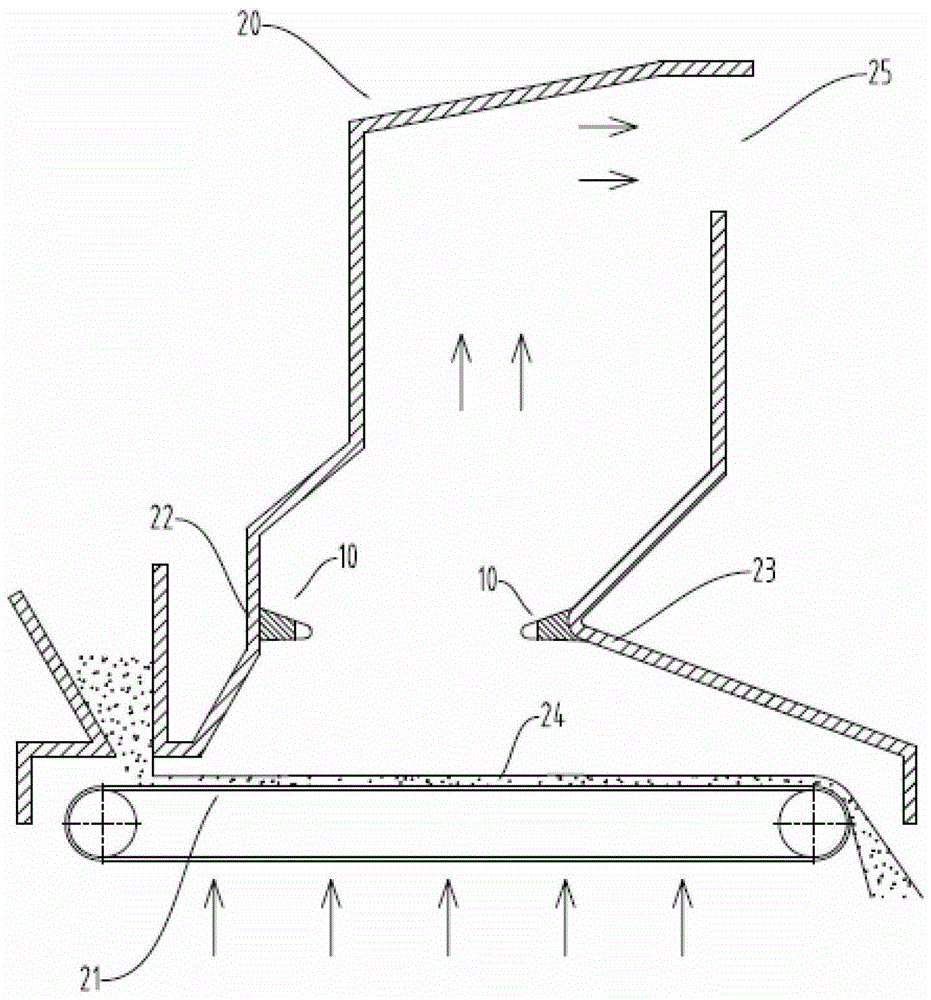

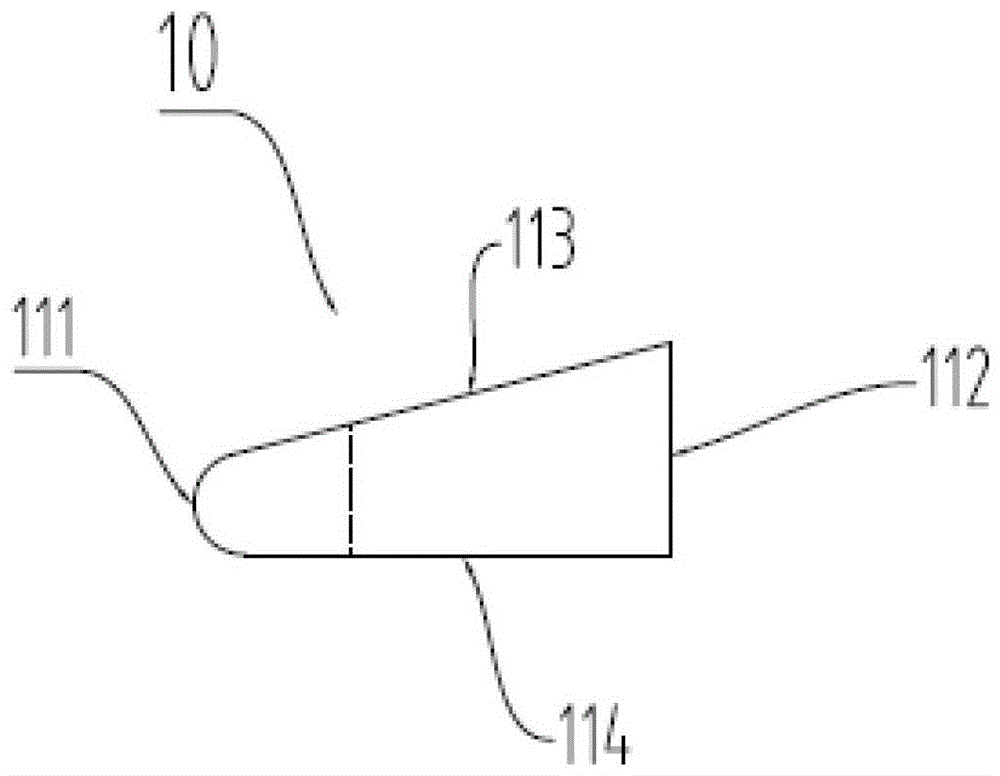

[0022] Such as Figure 1-4 As shown, the hearth 20 of the chain furnace includes a fire grate 21, a front arch 22, a rear arch 23, and an outlet window 25. The coal seam 24 moves slowly in the furnace chamber with the fire grate 21, and air is continuously blown into the furnace chamber from the bottom of the fire grate 21 to help The coal seam 24 burns, and the air blown into the furnace cavity simultaneously forms high-temperature flue gas with combustible particles and flows toward the outlet window 25. The present invention provides a wavelet flame disturbance expansion combustion device 10, comprising a main body 11 and at least two grooves 12, the main body 11 is a hexahedron, and the hexahedron includes an upper surface 113, a lower surface 114, a front surface 111, and a rear surface 112 , a side surface 115 and a side surface 116, the upper surface 113 is inclined at an acute angle with the horizontal plane, and the lower surface 114 is horizontal. A groove 12 is for...

Embodiment 2

[0027] In order to further enhance the disturbance effect of the small-wave flame disturbance expansion combustion device on high-temperature flue gas, another small wave flame disturbance expansion combustion device is provided in this embodiment.

[0028] Such as Figure 5 As shown, the present invention provides a small-wave flame disturbance expansion combustion device 10, including a main body 11 and at least two grooves 12, the structure of this embodiment is substantially the same as that of Embodiment 1, the difference is that this embodiment For example, the axes of the grooves 12 and the lower surface of the main body 11 are not perpendicular to each other, but are inclined at an angle to the lower surface, and the inclination directions of two adjacent grooves 12 are opposite. When the high-temperature flue gas passes through the inclined grooves 12, The flow channel increases, and the flue gas flows in opposite directions, which further enhances the disturbance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com