Ceramic tile paving machine

A technology for laying machines and ceramic tiles, applied in construction, building construction, etc., can solve the problems of difficult quality assurance, low construction efficiency, and high manual skill requirements, and achieve the effect of ensuring quality and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

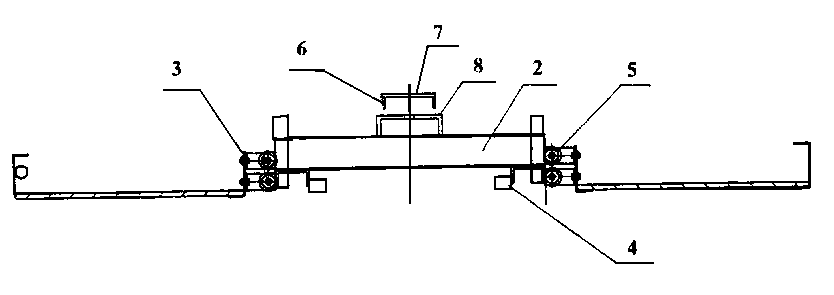

[0011] See figure 1 , figure 2 In the ceramic tile laying machine of the present invention, a motor 1, a traveling wheel of the frame, a ceramic tile laying frame 2, a ceramic tile laying frame lifting mechanism 3, and an electric control box are installed on the frame. The electric control box controls the motor. The motor is connected to the traveling wheels of the transmission rack. The rack traveling wheels at both ends of the rack move on two parallel station guide rails. The tile laying frame has multiple standard ceramic tile size frames, and the ceramic tile laying frame is connected by a lifting mechanism. Installed on the rack, the electric control box is also connected to drive the ceramic tile laying rack lifting mechanism 3 by controlling the motor 1. A guide wheel and a wheel cover 5 are installed between the ceramic tile laying rack and the rack, and ceramic tile laying is also installed on the rack. Lift limit block 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com