Degradable material and preparation method for anesthesia laryngoscope

A technology of anesthesia laryngoscope and base material, which is applied in the field of degradable materials and manufacturing methods for anesthesia laryngoscope, can solve the problems of iatrogenic diseases cross-infection, human health damage, environmental pollution, etc., and achieve good biocompatibility, Fast degradation and reasonable compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

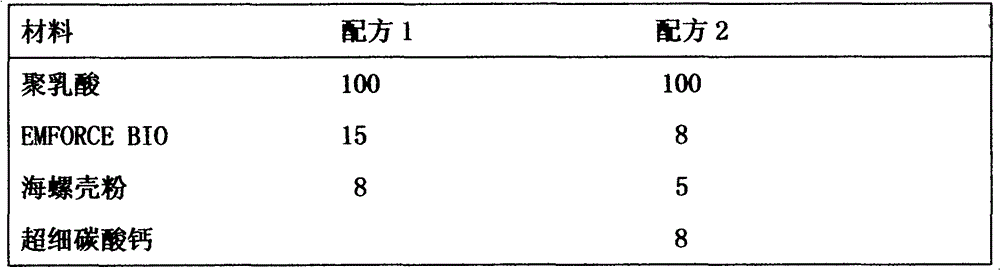

Method used

Image

Examples

Embodiment 1

[0026] The injection molding method of embodiment 1 anesthesia laryngoscope:

[0027] The first step, vacuum drying: the degradable substrate pellets of formula 1 or formula 2 were vacuum-dried at 50° C. for 3.3 hours, and then used.

[0028] The second step, injection molding: add the dried degradable substrate pellets of formula 1 or formula 2 to an injection molding machine for injection molding.

[0029] The barrel temperature is set as follows: feed inlet 150°C, compression section 160°C, metering section 170°C, nozzle 170°C;

[0030] Mold temperature: 20°C;

[0031] The injection pressure is: the first section is 75pa, the second section is 80Mpa, and the third section is 50Mpa;

[0032] Injection time: 55 seconds;

[0033] The holding time is: 0 seconds;

[0034] The screw speed is: 180 rpm.

[0035] Anesthesia laryngoscopes employing degradable substrates of formulation 1 or formulation 2 were obtained.

[0036] The above-mentioned embodiments have described the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com