Anti-fog sheet and manufacturing method thereof

A manufacturing method and technology of anti-fog sheet, applied in the field of anti-fog sheet and its manufacturing, to achieve the effect of improving light transmittance, reducing maintenance cost and improving effective running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

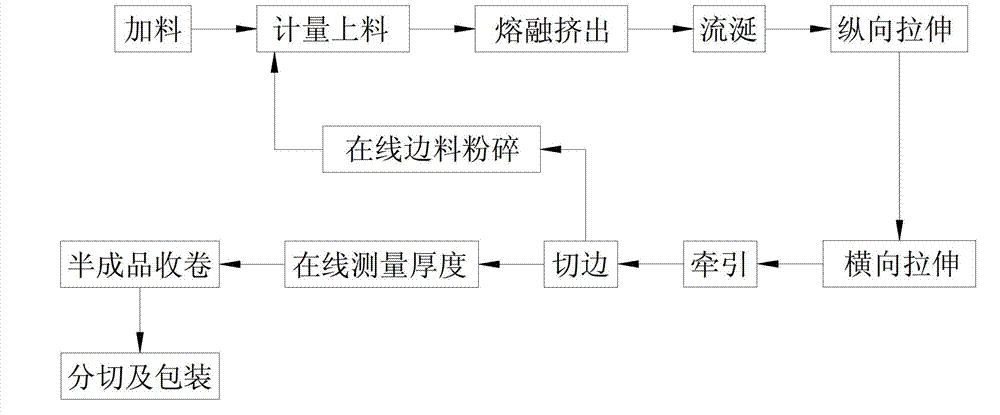

[0019] The present invention will be further described below according to the accompanying drawings.

[0020] Such as figure 1 As shown, an anti-fog sheet, including polystyrene resin, anti-fog functional masterbatch, is characterized in that: the polystyrene resin is 94.9%, and the anti-fog functional masterbatch includes anti-fog agent and White oil, anti-fogging agent is 5%, white oil is 0.1%.

[0021] A method for manufacturing an anti-fog sheet, which is prepared by the following process steps:

[0022] (1) Feeding, the raw materials composed of polystyrene resin and anti-fog functional masterbatch are added to the raw material silo, and the vacuum pump sucks the materials into the small hopper above the extruder;

[0023] (2) Metering and feeding. According to the process requirements, adjust the speed of the feeding motor of the small hopper, so that the feeding ratio of the small hopper reaches 20:1. The raw materials added according to the set ratio first fall into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com