Method for producing white dry powder building coating base stock

A technology for architectural coatings and white pigments, applied in the production field of white dry powder architectural coatings base materials, can solve the problems of high color uniformity requirements, poor color management, low production capacity, etc., and achieve the effect of controllable production quality and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The basic components include cement, powdered calcium carbonate (300 mesh in particle size), water reducing agent, and redispersible latex powder. Weigh the materials according to the weight ratio in Table 1, mix them evenly, and detect the whiteness of the basic components. The degree is 76.35.

[0040] Table 1, the weight ratio of basic components in Example 1 (unit: kg)

[0041] materials Portland cement calcium carbonate Polycarboxylate superplasticizer Redispersible latex powder weight 20 71.5 0.5 8

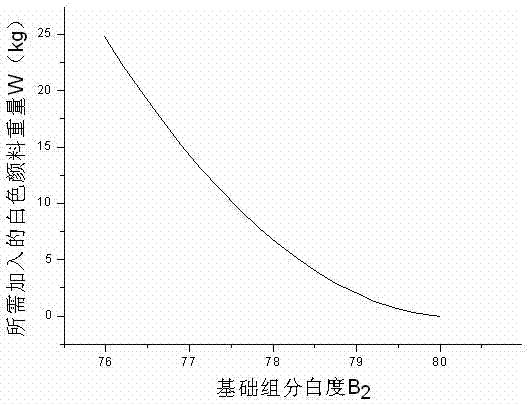

[0042] According to the B drawn in the above 2 For the relationship curve between W and W, find the ordinate value 20 of the point on the curve corresponding to the abscissa value of 76.35, which is the weight of the white pigment that needs to be added.

[0043] Weigh 20kg of white pigment, add it to the above-mentioned base component mixture, mix evenly, and the whiteness is 80.01, which is no obvious difference compared with the whi...

Embodiment 2

[0045] The basic components include cement, powdered calcium carbonate (300 mesh in particle size), water reducing agent, and redispersible latex powder. The materials are weighed according to the weight ratio in Table 2, mixed evenly, and the whiteness of the basic components is detected. The degree is 76.88.

[0046] Table 2, basic component material weight ratio in embodiment 2 (unit: kg)

[0047] materials Portland cement calcium carbonate Polycarboxylate superplasticizer Redispersible latex powder weight 20 71.5 0.5 8

[0048] According to the B drawn in the above 2 For the relationship curve between W and W, find the ordinate value 17 of the point on the curve corresponding to the abscissa value of 76.88, which is the weight of the white pigment that needs to be added.

[0049] Weigh 17kg of white pigment, add it to the above-mentioned base component mixture, mix evenly, and the whiteness is 80.03, which is no obvious difference compared ...

Embodiment 3

[0051] The basic components include cement, powdered calcium carbonate (300 mesh in particle size), water reducer, and redispersible latex powder. Weigh the materials according to the weight ratio in Table 3, mix them evenly, and detect the whiteness of the basic components. The degree is 77.40.

[0052] Table 3, basic component material weight ratio in embodiment 3 (unit: kg)

[0053] materials Portland cement calcium carbonate Polycarboxylate superplasticizer Redispersible latex powder weight 20 71.5 0.5 8

[0054] According to the B drawn in the above 2 For the relationship curve between W and W, find the ordinate value 10 of the point on the curve corresponding to the abscissa value of 77.40, which is the weight of the white pigment that needs to be added.

[0055] Weigh 10kg of white pigment, add it to the above-mentioned basic component mixture, mix well, and the whiteness is 70.03, which is no obvious difference compared with the whitene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com