Constant-current and constant-voltage composite type floating hydrostatic guide rail and control method thereof

A technology of static pressure guide rail, constant current and constant pressure, which is used in manufacturing tools, large fixed members, metal processing machinery parts, etc., can solve the problem of not being able to meet the high and low speed indexing functions of the turntable at the same time, and achieve convenient control methods and simple structures. , Improve the effect of bearing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, technical content of the present invention is described:

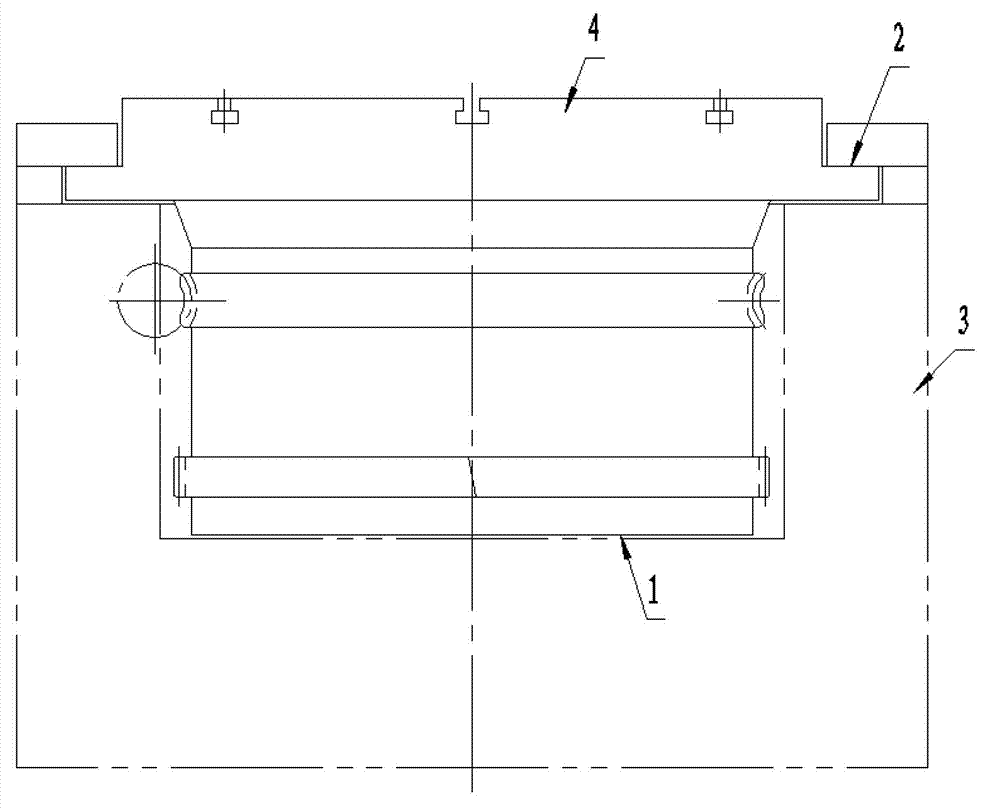

[0036] Such as figure 1 , the turntable is axially supported by the closed static pressure guide rail composed of the main guide rail 1 and the reverse preload guide rail 2. The main guideway 1 is a constant current static pressure guideway, which is composed of a moving guideway and a static guideway. The main guideway on the work surface 4 is a moving guideway, and the main guideway on the base 3 is a static guideway. The reverse preload guide rail 2 is a floating static pressure guide rail combined with constant current and constant pressure. The constant pressure system controls the size of the reverse preload, and the constant current system controls the thickness of the oil film.

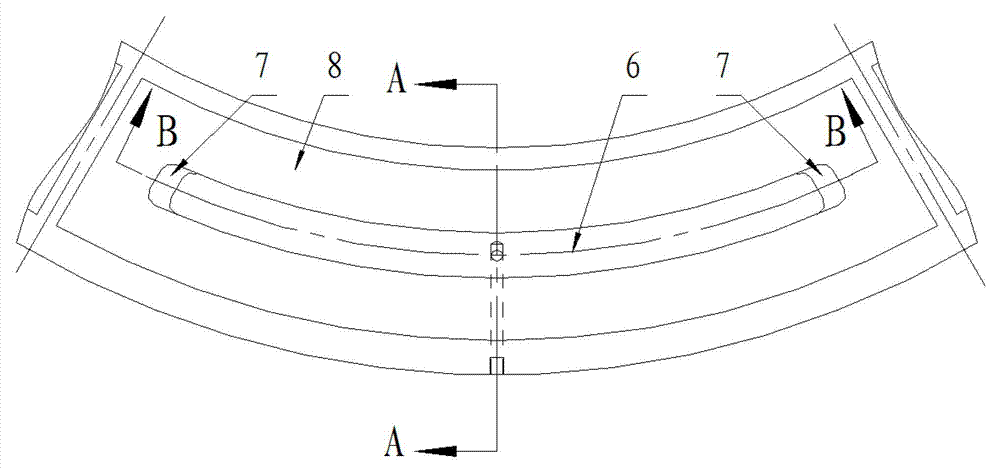

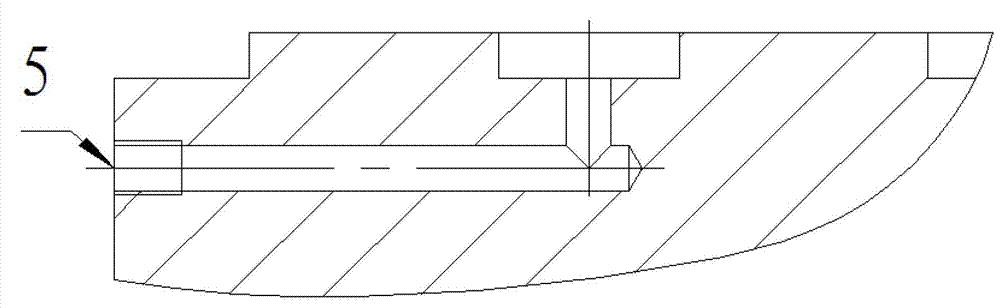

[0037] Such as figure 2 , Figure 2A , Figure 2B , the static guide rail of the main rail is a deep and shallow oil cavity structure, the shallow oil cavity 7 is distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com