Plasma apparatus for the abating emissions of per-fluoro compounds and plasma vortex reactor for making the plasma apparatus

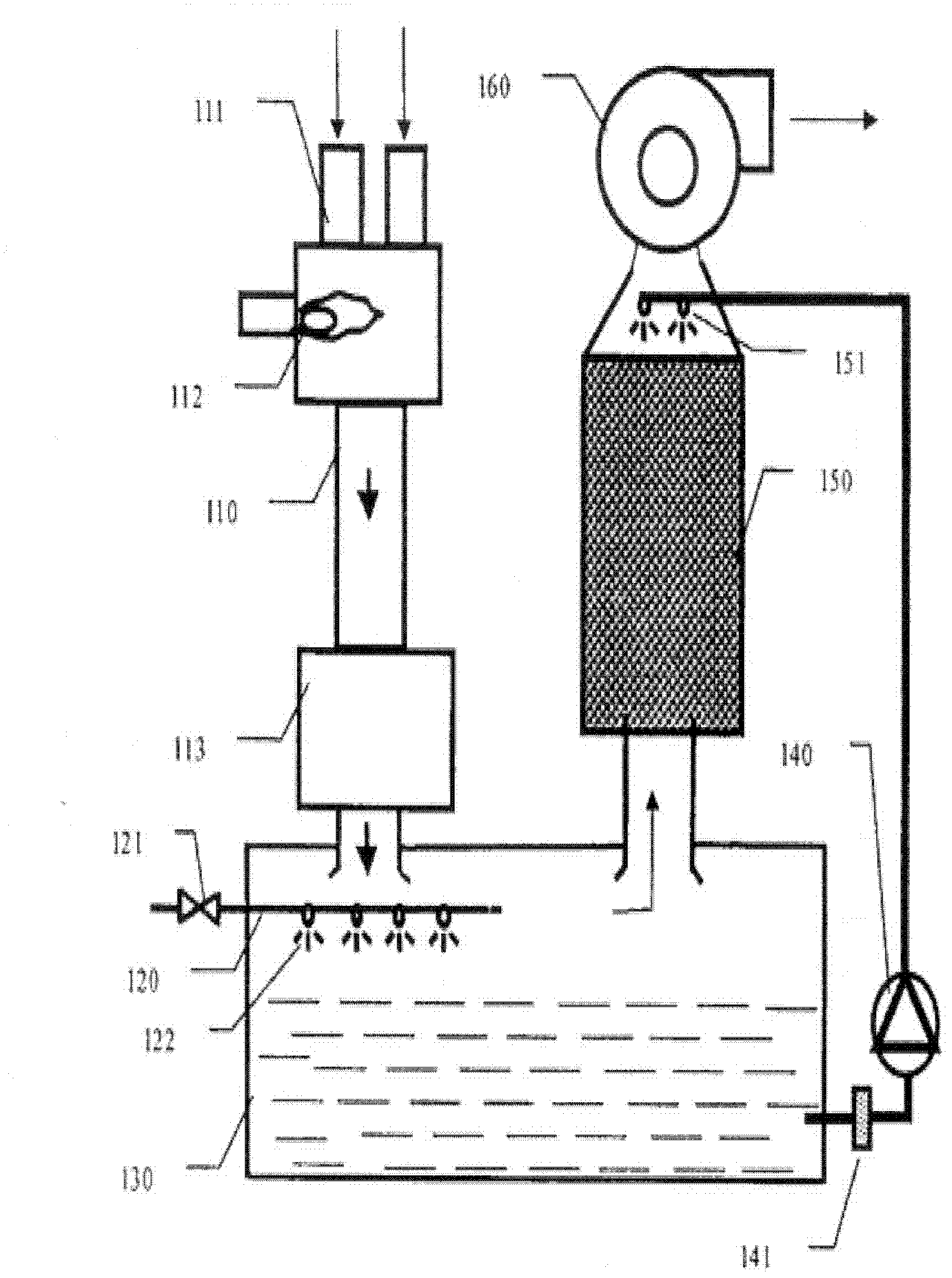

A plasma and processing device technology, applied in the field of plasma processing devices and vortex plasma reactors, can solve the problems of destroying perfluorinated waste gas, particulate matter pollution of pipelines and downstream equipment, and the impact of wet scrubber 150 cleaning performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

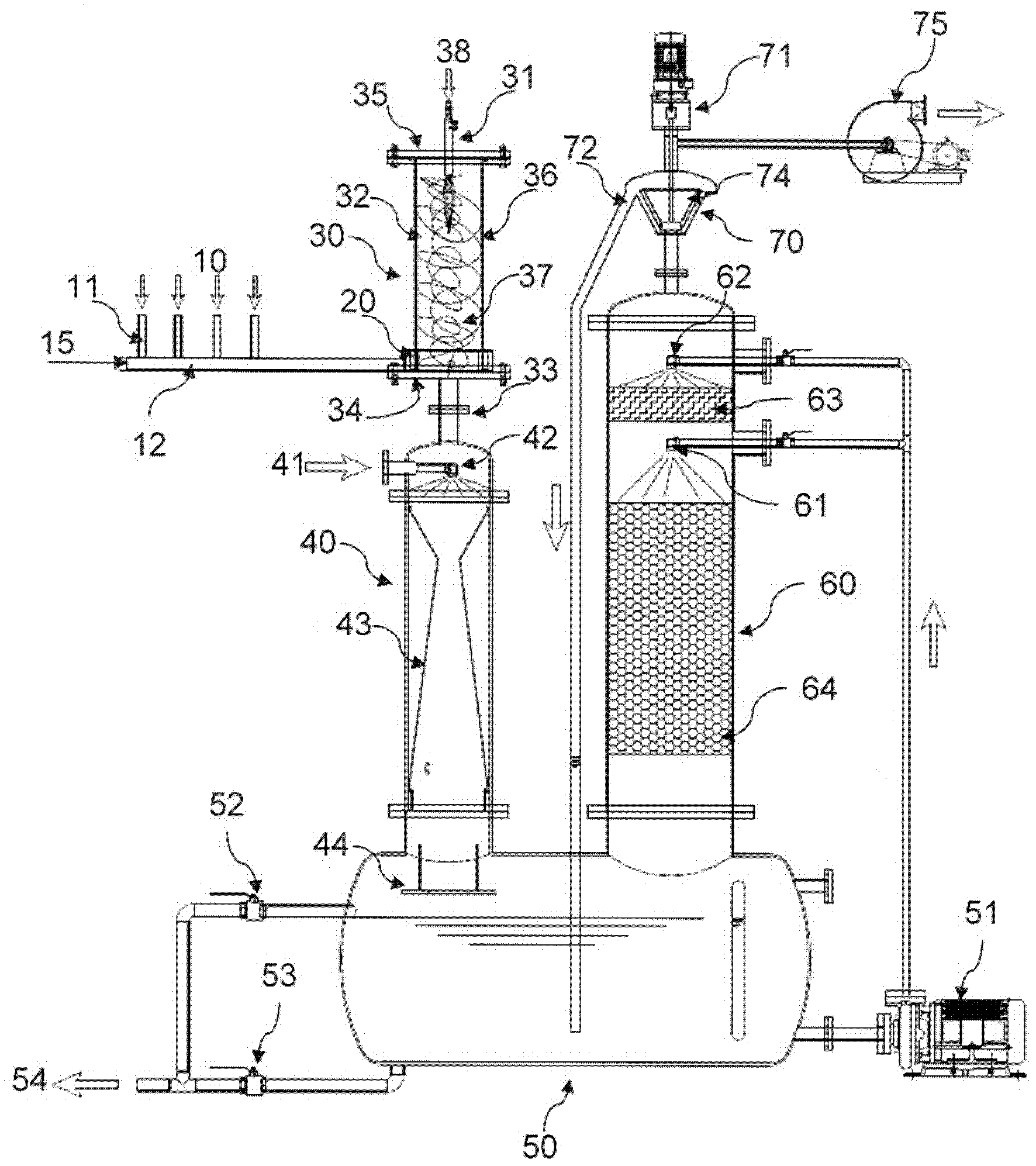

[0059] Such as figure 2 Shown is a preferred embodiment of the plasma processing device for perfluorinated compounds of the present invention, and its principle and operation will be described below.

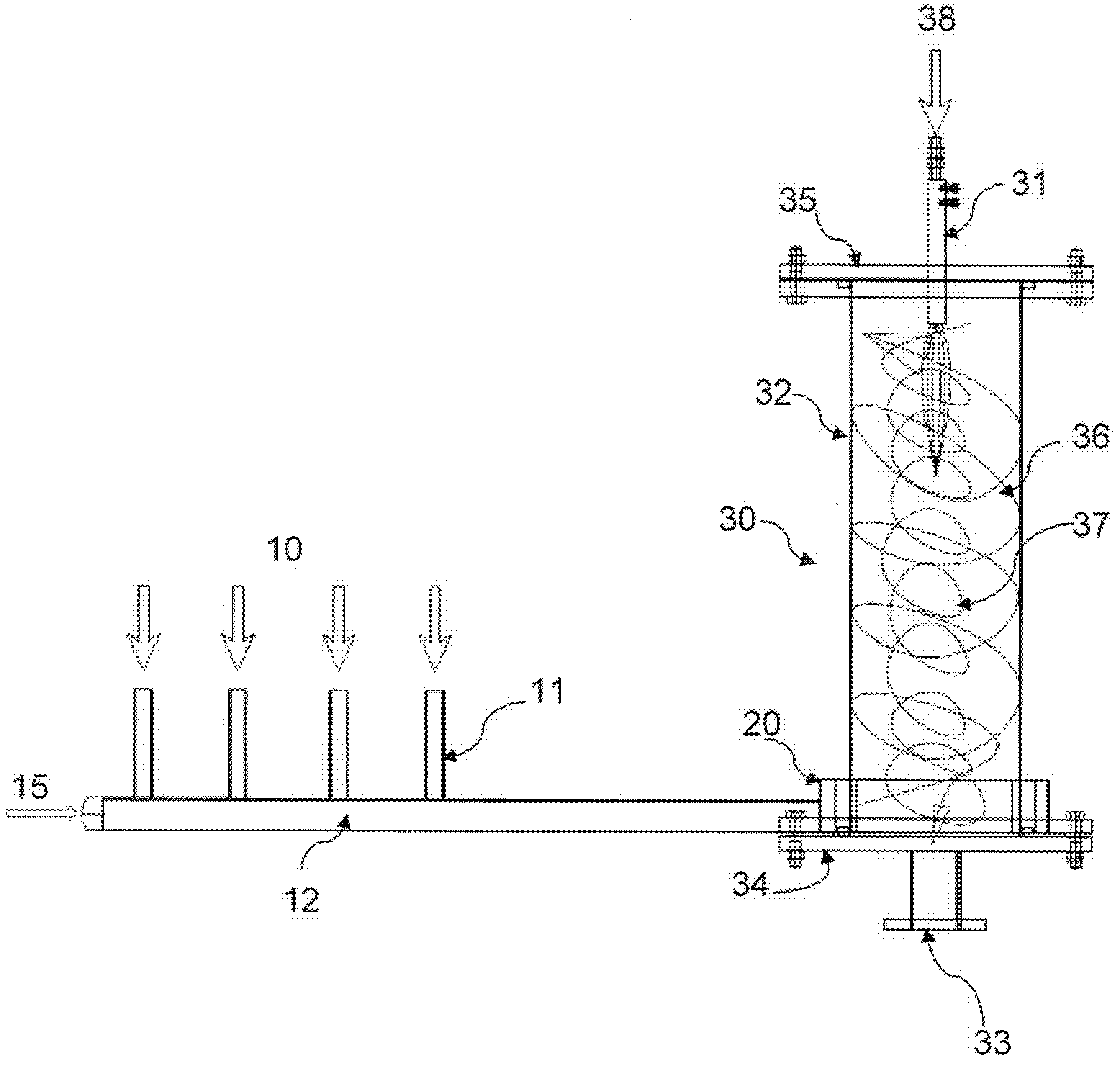

[0060] The plasma processing device of perfluoride of the present invention is a kind of utilization perfluoride waste gas to inject in the vortex plasma reactor 30 with tangential line, make it generate cyclone vortex, in the vortex plasma reactor 30 interior utilize The DC plasma torch 31 at one end pyrolyzes the perfluorinated waste gas, uses the Venturi scrubber 40 and the wet scrubber 60 to wash and lower the temperature to remove acid gas and particulate matter, and then uses the foam remover 70 to entrain the airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com